I'm not an engineer, nor do a play one... anywhere....

I'm just interested in timber frame engineering.

Ditto, my hands are too torn up to claim anything more than being a simple carpenter. I do think we build better the more we know, I also hope Ken calls it if we step off the path.

Mike is right, tightening is not part of the consideration here, but the joint shouldn't be sloppy. The design values count on the connector being in shear, a gap will also put some bending in the dowel that was not considered.

Dowel, the NDS term for this type of connection covers nails, screws, lags, bolts and drift pins. Steel "dowels" are used in the NDS since they are the most common wood to wood connection, so what has been extensively tested. The NDS gives minimum specs on the yield strength of the steel in the various diameter dowels, this assures that the dowel is up to the loads listed in the tables. You'll need to check the peg report to keep its stresses within limits. This is the beginnings of the testing that will establish a wood dowel table. I hope to see that in the NDS in another cycle or two. There is actually enough info now to make a preliminary table that would probably be less confusing and thus safer than what we're doing here. But, that's why engineers make the big money.

Some specs;

The NDS minimum edge distance when loaded perp to grain is 4D from the loaded edge, 1.5D from the unloaded edge, that's your mortise. When loaded parallel to grain minimum edge distance is 1.5D , that'll be the minimum edge distance for the tenon. That takes care of edge distances...

End distances;

For the tenon, end distance(relish), loaded in tension, parallel to grain, hardwood, 5D for full design value, for reduced value the minimum can be down to 2.5D. In softwood 7D, min 3.5D. The strength reduction is linear, Cdelta=actual end distance/full design value distance.

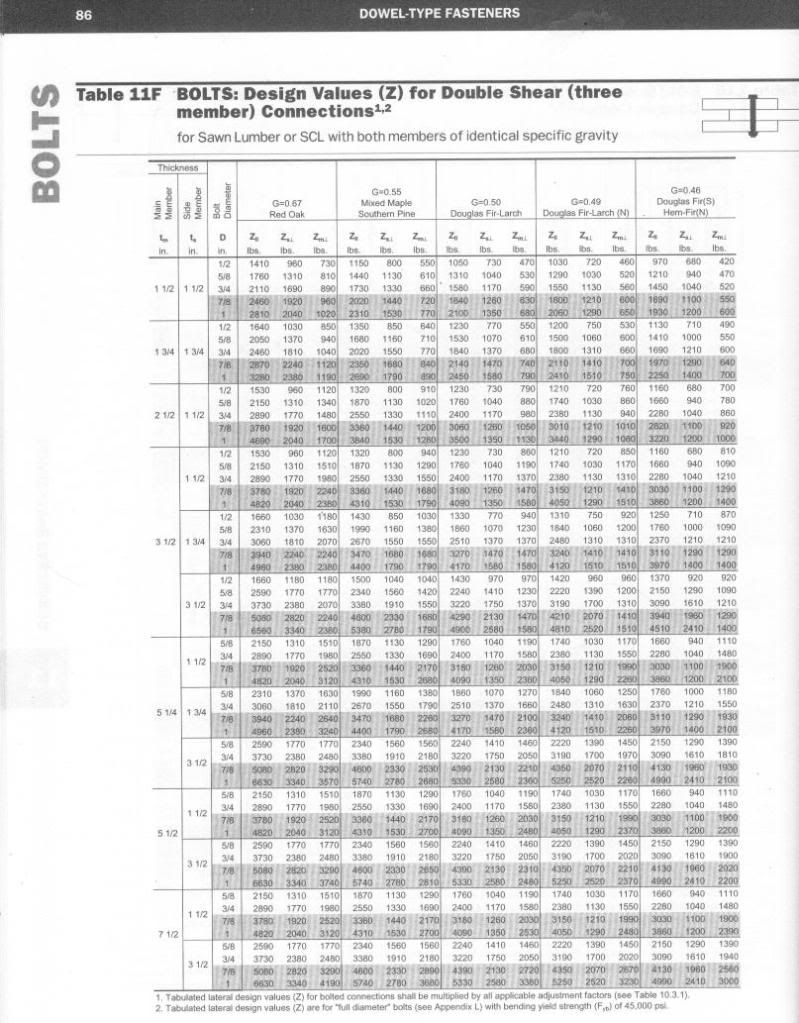

Without seeing a table this is probably getting pretty deep for alot of folks so for educational purposes I've scanned a page from the NDS. This is for a bolt in double shear, a tenon in a mortise. The main member here is the tenon. The side members are in tension perp to grain. Look across the top at the red oak column, the middle column under that heading "Zside perp" column is us. Look down the left edge if the tenon is 1-1/2" thick and the mortise sides are >1-1/2" then we are good to go. A 1/2" dowel is good for 960 lbs, 5/8=1310, etc.

As an example; Assume this is a red oak porch plate and we have a bit under 1000 lbs uplift. We need to adjust the design values for duration of load. Wind is short term so we can multiply the base design value by 1.6. lets check a 1/2" bolt... 960x1.6=1536lbs, OK. A 1/2" bolt would work so our edge distance would be 4x.5"=2" edge distance for the mortise. For the tenon end distance it would be 5x.5"=2.5" end distance. That worked but it was pretty crude.

You can interpolate from the table for a 2" thick tenon but the connections calc would be easier;

http://awc.org/calculators/connections/default.htmI've set it up for our example but using an 8x8plate and 2" thick post tenon to see if we can get better results;

http://tinyurl.com/yautmr5I made it with a 3/8" bolt so

4x.375"= 1.5" edge distance

5x.375"=1-7/8" end distance on the tenon

Still need to check the peg for the load but this hopefully gave a quick rundown of how to do the edge and end distances... for a single peg.