Brad I don't ever recall seeing this drawing before? Sorry I missed, or overlooked it at some point. I did not do this intentionally and would love to know which post it was on if you could share that with me. I dislike missing things like that.

If...mixing and matching...systems of layout works for your style of timber framing, by all means employ such an approach. I wouldn't suggest to anyone that they stop using what works for them...I would only suggest that there maybe better, and/or easier approaches. I am always studying systems to learn more about the craft, or hone the systems I do employee. Further, I completely believe you could lay the example timbers out just as you describe...and I appreciate you query in how this could be possible with Line Rule. In small order, all I can say to that is one needs to fully understand all three systems completely to understand their comparatives, thus understanding how one is faster than another and perhaps (overall) much simpler to use.

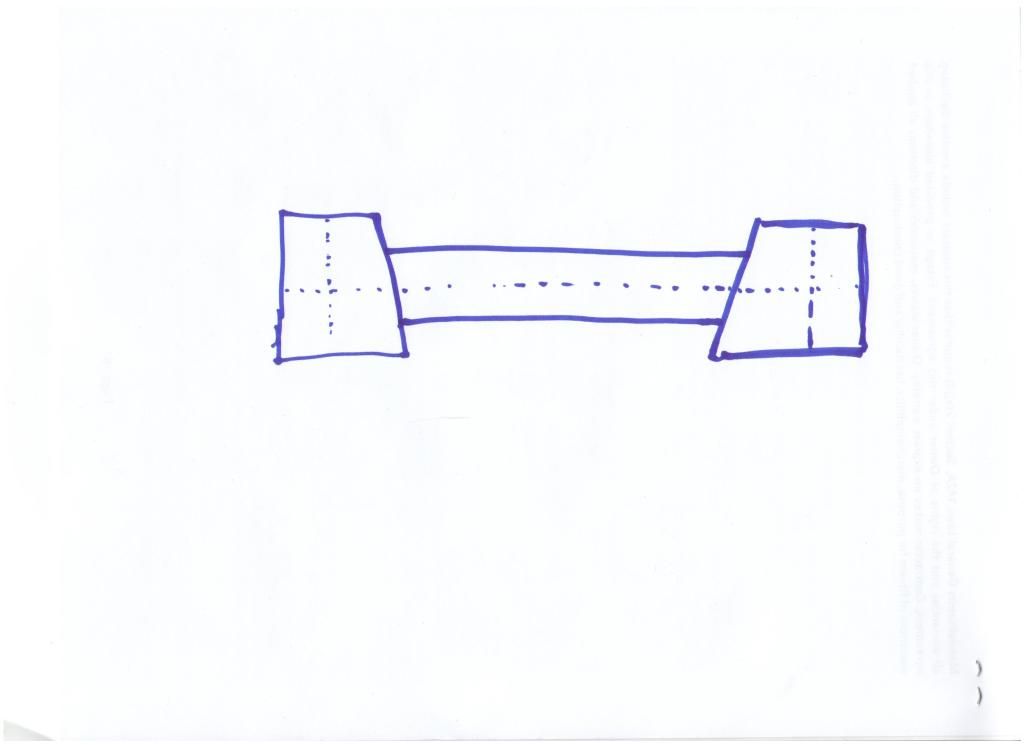

In the case of your drawing, if the timber configuration exists...as is...within your drawing as described, then laying this out with Line Rule is not only faster, it would be much more accurate than employing the Edge Rule system to a great degree (in my experience with all three systems) as I understand them. The only system that I know of that could even come close to the level of accuracy within all three of them (and match it in quality) would be Scribe

Rule accept this is much more labor intensive, generally slower, and involves all timbers being present together at one time.

I would further point out that with Line Rule (and its related templating and scribing systems that typical work in concert with it as it relates to Asian layout modalities that employ it) the posts could very well be in one location, and the connecting timbers in another, with little to no ill effect to accuracy of fit once the frame comes together. They could even be Live Edge and whether at sill, midspan or eave plate location has little bearing at all.

I grant the comments above are more a statement of application experience than a procedural outline. I would have to actually teach and/or illustrate to much greater detail the procedural elements if one is not acquainted with them, and there are many text and publications (mostly in Japanese, Korean, and related languages) that cover well this topic...much better than I could here in this brief post.

I can expand that I have seen done and done myself, very similar fittings to the one illustrated with not only...out of wind...timbers but those with tapers and live edges as well...which of course...brings into play scribing and templating systems as they apply to Line Rule methods of layout...yet not what we would typically find (overall) in the European systems of scribing.

I think Sean of Hylandwoodcraft...who is following this post thread and has fully embraced Line Rule yet understand thoroughly Edge Rule...could expand on this further from a different view point perhaps? With his added value perspective, I might be able to expand this reply in better context and application or procedural understanding...I am not sure?

You can't measure the distance off of the centerlines in this case. And what if it came in at an angle?

I must be (and very well could be?) missing something in regards to the above statement. I can (and have) measured off of the...reference lines...(we don't typically call them centerlines as often they are not just in the center of a timber...and...there may well be more than a single reference line such as on live edge and curved timbers.) Angles too have no context...other that what those angles may actually be (measured or empirically templated.) Further, all four sides of the timber could very well have (if one really wanted to make things this complicated for a visual aesthetic or artistic statement) completely different angles as well.

Or what if you didn't know the width of that center beam yet (you're trying to cut the mortise in one of the outer posts?

Again, I may be missing something? From the statement I will take it to perhaps reflect some scenarios I have experienced in the past where part of a frame is in one shop and the rest of the timbers to be jointed are someplace else. In that context, standardizations within the working model would be agreed upon by all active participants to the frame. As such, the standardization (even with live edge members) would still dictate your housing depths and related criteria to such joint unions.

As to being dogmatic in view, I don't believe I am (no more so than anyone else that may have a deeper understanding or experience with some topic.) I think anyone can agree that there is the existence of...bad ideas...be it in a topic like human trafficking/slavery, or something as simple or mundane..like a building system...That does not make it dogmatic I don't believe, just a commonly held perspective among a given group of individuals. The group of Timberwrights I work and associate with most commonly do not care for SIPs in general...particularly commercial SIPs...or any of these general insulative diaphragm approaches accordingly for a number of reason not germane to this layout post topic. If we do employ elements of this insulative diaphragm concept within some context of this system, or its applicable architecture application, we typically build them ourselves from raw material...