Posted By: mo

set back mortises - 06/25/08 11:07 PM

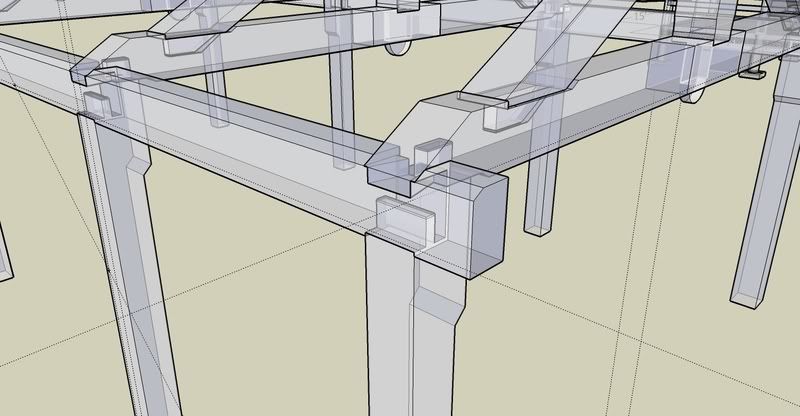

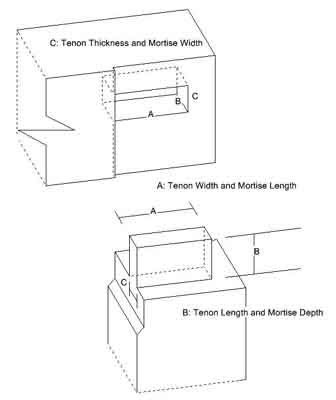

Hi all, I have seen this practice in a few shops now and was wondering how many are designing and cutting like this. Basically instead of mortising from the face of the intersecting timber the mortise is then inset X from the face so that four shoulders are created. I guess shops do this reduce visible sloppy mortises but I think it only adds to the problem ("just cut the tenon back some more" or lay-out doesnt need to be perfect). The braces are cut the same way (setback mortises for lack of a better term) only adding to design time for stick drawings, layout time, cutting time, and alleviating the consequences for bad mortising and cutting. Only on pieces with out housings in mill rule. Does anyone think that this adds up to too much wasted time (a lot more tooling, I'd would say twice as much on the stick below)?

*not to scale

*not to scale