I just did a little figuring, this could be cool, If I'm doing my math right, apparently by dumb luck I'm at the hairy edge of breaking this thing.

for the purposes of quick math, if you weigh 200 lbs, each of the 7 "spokes" only need support 28.5 pounds.

So if we carry that thought further... At my weight I point load each rafter with 27 lbs.

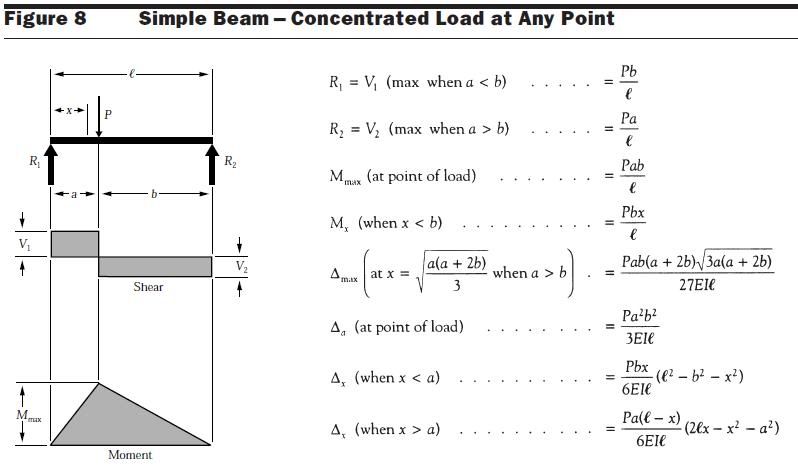

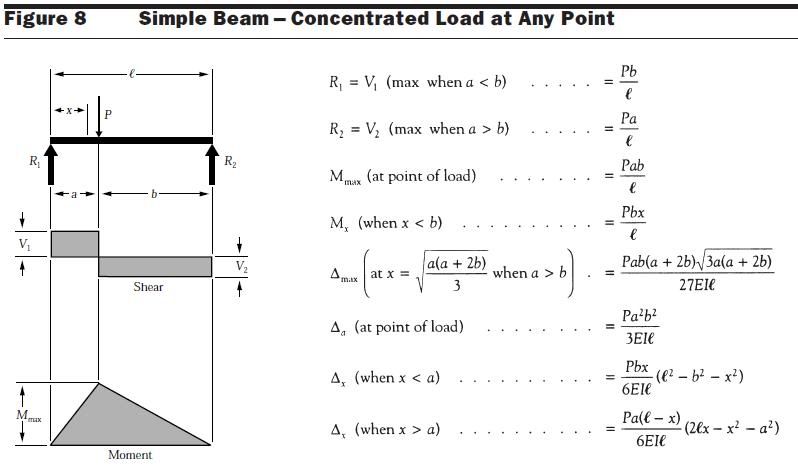

Each rafter in this case is simply supported beam. With a point load at a distance-"a" from one end.

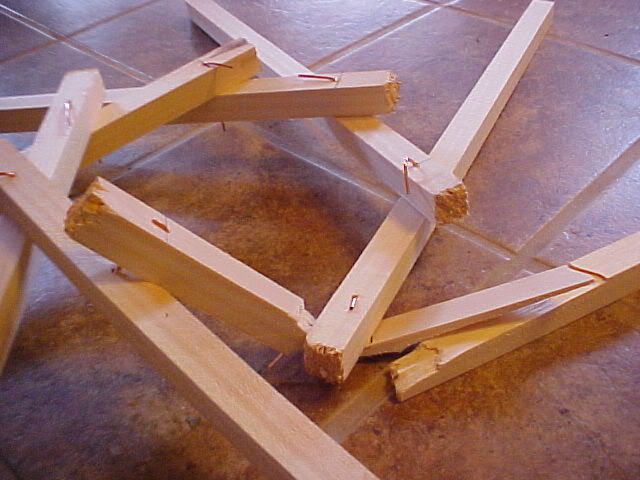

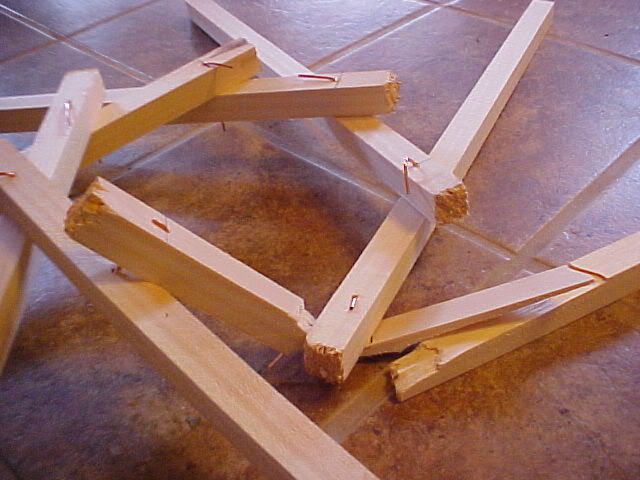

I measured the sticks, they are 19" from the foot to the upper hole, 15" from the foot to the lower hole, so the holes are 4" apart. The sticks are 15/16" square (.9375")

Maximum bending moment is under the joint in the 2 rafters

Mmax=Pab/L

Mmax=(28lbs*4"*15")/19"

Mmax=(1620)/19

Maximum bending moment=85 Ft/lbs

Section modulus required= (Mmax * 12)/Fb This was clear (Select Structural) white pine so NDS allowable Fb is 1250psi.

Sr=(85 Ft/lbs*12"/ft)/1250psi

Sr= (1020 in/lbs)/1250psi

Section modulus required=.816"^3

The formula to determine section modulus of a rectangle is (breadth *(depth*depth))/6

I drilled a 1/8" hole vertically through the rafter at the point of maximum bending moment.

Sm= ((.9375-.125)*(.9375*.9375))/6

Sm= .714/6

Section modulus of my rafters=.119"^3

I would need a section modulus of .816 to be code, I had .119, so I was just a tad overstressed, by code it would need to be about a 1-3/4"x1-3/4" rafter in the model to be safe. But it didn't break... I wondered why. I pulled out the "Wood Handbook" and looked up the Forest Produts Labs test data. Average modulus of rupture for clear, dry, white pine is 8,600 psi

Going back to Sr= Mmax/Fb I plugged in average modulus of rupture for Fb

Sr=1020/8600

Sr=.1186"^3 I was a cookie away and living dangerous

There have been more posts since I started ciphering and we got rained out today;

Timbeal, I bent the copper wires straight on the underside this morning, they were just an L shape to keep them from dropping out. Stepped up on it and no difference, held just fine. There is some thrust caused by the deflection of the rafters but not the thrust of an untied pair of rafters. IMO if the rafters were sized correctly for deflection then there would be no thrust. Seems like it would be simple enough to put a tension ring around the outer perimeter though.

Since it hadn't failed yet I had my wife start handing me books.

It supported 230 lbs and failed at 235 lbs, the failure was at the hole, the point of maximum bending. Backtracking through the math;

235/7=33.57lbs/rafter

Max moment was 106 ft/lbs

That works out to a MOR of 10,690 psi.

My guess here is that my test apparatus is not frictionless so some of the load was "absorbed" as axial column type loading between the rafter foot and the floor, the deflection thrust. But, off the top of my head that is also within the coefficient of variation in the material, maybe my white pine is better stuff than I thought. I'm not positive of any of this, still just trying to wrap my head around it.

Thanks for the links bmike, more to read.