Tim – Good to hear your Plumbette is still finding itself in use in your shop. I've been making Drops off & on all week myself.

Ah, camber, often seen as a measure of success and used as a measure of a bridges health...

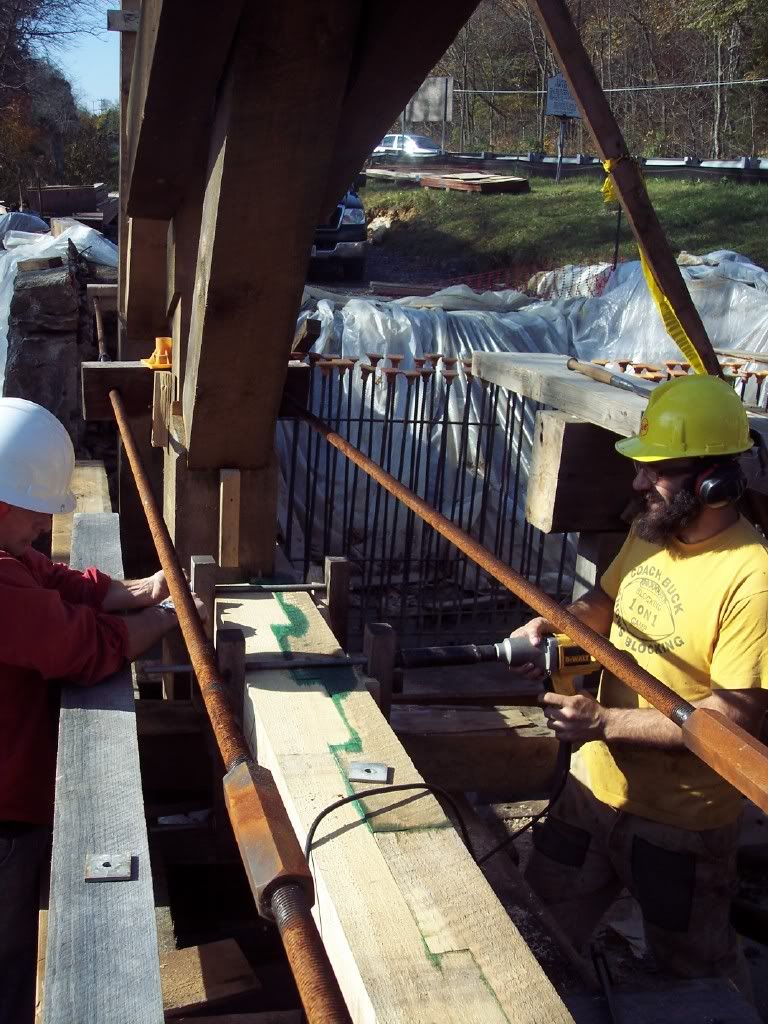

It really depends on the situation, in the case of the Moose Brook Replication, like Railroad bridges in general and a short one in particular, it's camber was, and will again be minimal at just an 1 1/4”-

With the exception of the salvaged Iron, with it being entirely new construction / framing, and with the scarf free Bottom Chords, I don't expect we will lose all of an 1/8”

Even in the restoration of historic spans, (when you're often recovering from quite severe negative camber) the loss in camber when loaded should be minimal. In the last major rehab we did, the negativity was 10” in the upstream truss and measureable in feet in the downstream. A catastrophic failure shortly before the get go had it sitting in an untypically semi-dry riverbed, this makes for some unusual and severe crush which must be dealt with – An enemy as common as the neglect which created it, yet one recoverable from.

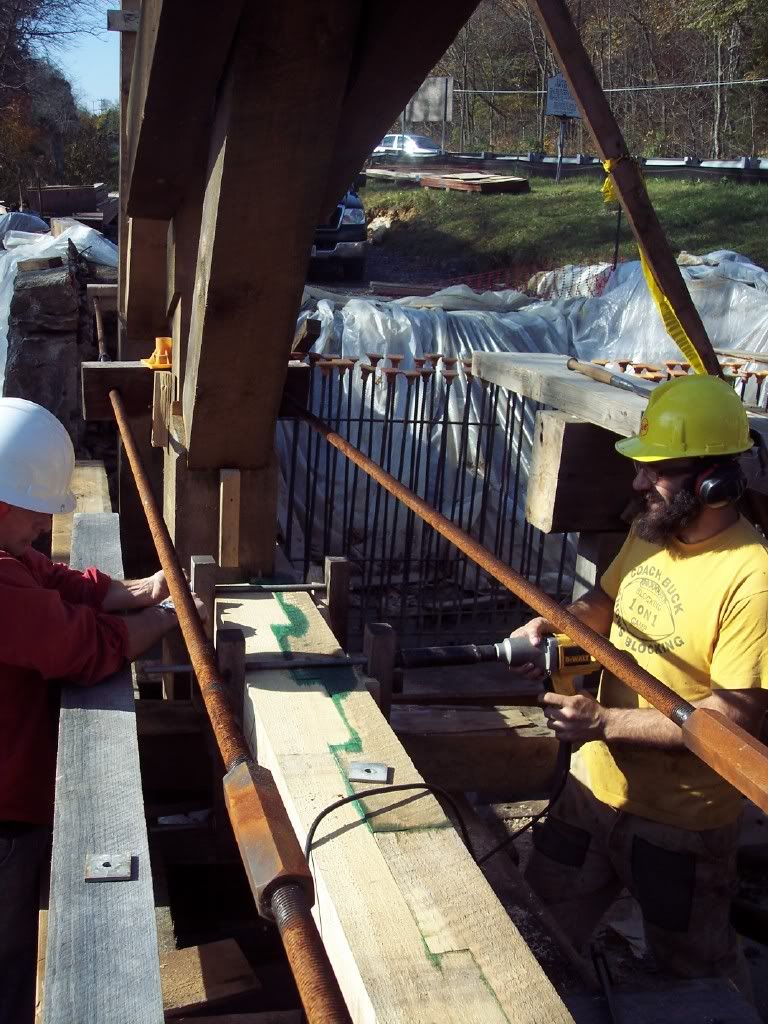

It had Chord Scarfs in every panel – Here we overcome extreme friction in a necessarily tight fit between a Shear Key and two inner Chord Lams.

The resultant 7 ½” camber created with slightly angled (always always in bridge work, you strive for the required full bearing everywhere) Chord Abutments (Butt to Butt joints) and the direct scribing of the Shear Keys to them.

At the reluctance of, but with the cooperation of the Eng of Record, we first loaded the Trusses, (contemporaneous written description and photographic evidence suggests that with good reason this was the order of things) and lost something in the neighborhood of a half inch. We then loosely shimmed the bridge back to the shoring, and kept adding dead load (flooring, rafters and the skip sheathing on them) pulling shims daily as we added more load, and tuned up the Arch Abutments to re-establish full bearing at all joints. Only then did we fit the Arch ends to the Skew Backs on the Bridge Abutments and prepared to load the joined systems.

We prepared to measure deflection and loading in multiple ways for this occasion, comparing a benchmark established at truss loading (another 3/8” as dead load was increased) with the transit readings before pulling the falsework, while at the same time, members of the nearby Johns Hopkins Eng Dept set up strain gauges and the other necessary equipment to collect data –

We then freighted up the bridge with a rolling live load quantified on the scales at the local truckstop. Here we take a transit reading whilst the good Doctor crunches her data.

Forget who came closest in the pool, lost another 1/8” when we cut 'er loose, all told we lost about an 1”- If we were to build the same bridge from scratch, I'd expect way less. All said, we were left with the kind of camber the bridge told us it did once have, but had lost 75 years before when all the floor beams but one and all the flooring had been changed out for mixed hardwood, a huge error adding immense dead load. An error based in the false assumption that stronger is always better.

For the New Moose Brook the documentation should be even greater, it's headed out to the Eng Dept at Case Western Reserve and their new structures lab to be used as a full scale model, they plan to load it up to about 80 kips. When it someday returns to NH (about a year in the lab) it is expected to carry trains again at one of the area RR museums.