When designing joinery, I usually start with establishing some "general frame rules."

These are rules that most if not all of the joints of the frame will have to adhere to.

Some standard general frame rules I use when designing a square rule frame are:

General Frame Rules:

1.) All timbers are framed down to the next one half inch in size.

2.) Joints are laid out two inches off the layout face and two inches thick.

3.) Bents are laid out from the South, except the North most bent.

4.) Braces are framed to four inches thick.

5.) All tenons are trimmed by 1/8" in length.

For quite some time I've been using the first four and just added the last one as it was assumed by me that everyone knew this, and I found that not everyone does.

When we cut joints here, during workshops, we cut the reference side of the joint first to establish that it is correctly spaced off the reference side. And then we make the tenon the correct thickness taking the back off and working down towards that thickness.

After that is done we have the tenon the correct offset of the reference face and also thick enough, we make it the correct width.

That usually means trimming off one side to the 1/2" under rule and creating the reduction along the timber.

When a tenon is joining a beam near the end of the beam there is a short section of the beam left to have enough relish on the end of the beam to make a mortise on all four sides of the tenon.

But when the tenon joins a beam in the middle it usually is flush to one side, the adjacent side. If it is housed then the mortise shouldn't show much when the timber shrinks.

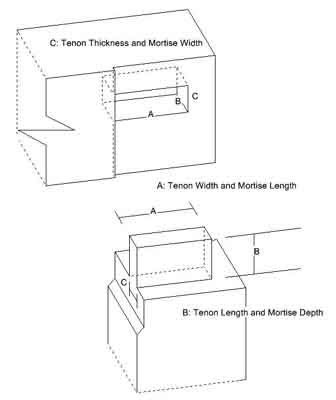

One good drawing I saw years ago in timber framing and one that I have recreated to use to teach the correct terms is this one:

Jim Rogers