|

Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22847

02/28/10 12:13 AM Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22847

02/28/10 12:13 AM

|

Joined: May 2009

Posts: 14

johninnh

Member

|

Member

Joined: May 2009

Posts: 14 |

Well, I got the photo part figured out. Here is the picture.  This was also green and was a lot of work to handle. It was our first time and took a little practice before we were ready for this shot.

|

|

|

Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22855

02/28/10 03:01 AM Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22855

02/28/10 03:01 AM

|

Joined: Jun 2007

Posts: 108

Craig Roost

OP

OP

Member

|

OP

Member

Joined: Jun 2007

Posts: 108 |

Tim,

When I first used the gin pole it was green and I had peeled the bark off. The angle of lift was 60 degrees on the 20ft hand-hewn oak bent with minimum flexion or bending. And the angle of the lift for the sawn pine bent was greater than 60 degrees and the gin pole flexed enough for me to feel that it would snap. It is my opinion that if the flexion was the same for both lifts that happened 3 years apart that the second lift in question using the seasoned pole and the lack of moisture caused it to become brittle and not as solid as if it were green. The idea behind bending a green tree or sapling such as used in a animal snare, once triggered causes the sapling to spring back. This would not be possible with a dry or seasoned tree. The saying "strong enough to bend" comes into play when speaking of green gin poles. IMHO

Rooster

Yah-fur-sur, You-betcha, Don't-cha-know!

|

|

|

Re: Share your gin-pole systems.

[Re: Craig Roost]

#22856

02/28/10 03:22 AM Re: Share your gin-pole systems.

[Re: Craig Roost]

#22856

02/28/10 03:22 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I would almost question the size of the pole in this situation. Maybe a hardwood pole of the same size would not be an unreasonable possibility. Or even two poles.

Tim

|

|

|

Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22857

02/28/10 05:37 AM Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22857

02/28/10 05:37 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

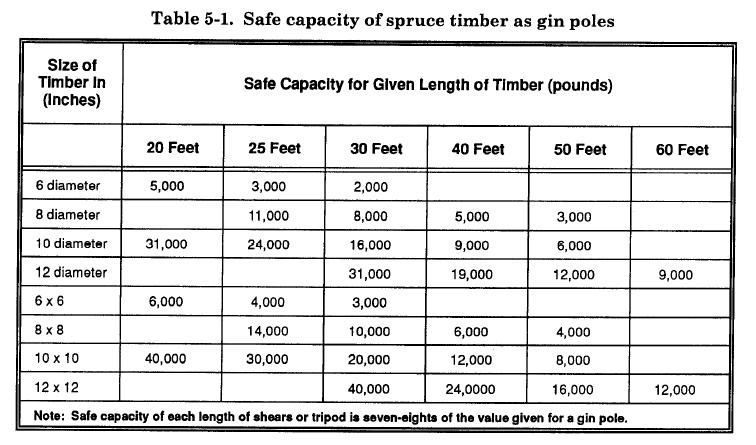

This is from the Army Rigging Manual posted earlier.

|

|

|

Re: Share your gin-pole systems.

[Re: Don P]

#22858

02/28/10 07:30 AM Re: Share your gin-pole systems.

[Re: Don P]

#22858

02/28/10 07:30 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Jim(R).

Re the pictures of your tractor and gin "tee" pole, why don't you put the "tee" inside the bucket and then you would have a crane ?

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: Share your gin-pole systems.

[Re: Ken Hume]

#22859

02/28/10 01:44 PM Re: Share your gin-pole systems.

[Re: Ken Hume]

#22859

02/28/10 01:44 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

As long as the hydraulics don't leak down that could assist in certain areas. I used a tractor bucket to hold something in place once, after going around with my water level I came back to my bench mark to find it was not right....back around to see where the issue was, when it was the bucket settling. The tractor bucket was holding my water level bucket, that was a half hour well spent.

The chart, sizing gin poles, is that for a specific angle, say a straight vertical lift? Or can the pole be tilted or the load lifted from a distance, inputting different loads on to the pole? What does the chart really tell us?

Tim

|

|

|

Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22861

02/28/10 02:05 PM Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22861

02/28/10 02:05 PM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

I'm pretty sure I own the copyright,

A gin pole consists of an upright spar that is

guyed at the top to maintain it in a vertical

or nearly vertical position and is equipped

with suitable hoisting tackle. The vertical

spar may be of timber, a wide-flange steelbeam

section, a railroad rail, or similar

members of sufficient strength to support

the load being lifted. The load may be

hoisted by hand tackle or by hand- or

engine-driven hoists. The gin pole is used

widely in erection work because of the ease

with which it can be rigged, moved, and

operated. It is suitable for raising loads of

medium weight to heights of 10 to 50 feet

where only a vertical lift is required. The

gin pole may also be used to drag loads horizontally

toward the base of the pole when

preparing for a vertical lift. It cannot be

drifted (inclined) more than 45 degrees from

the vertical or seven-tenths the height of

the pole, nor is it suitable for swinging the

load horizontally. The length and thickness

of the gin pole depends on the purpose for

which it is installed. It should be no longer

than 60 times its minimum thickness

because of its tendency to buckle under compression.

A usable rule is to allow 5 feet of

pole for each inch of minimum thickness.

Table 5-1, page 5-2, lists values when using

spruce timbers as gin poles, with allowances

for normal stresses in hoisting operations.

Off topic Tim, I was helping relevel a barn and had told my helper to put his thumb over the water level tube while we walked to opposite ends of the building. I couldn't get it to make any sense when I looked around the corner. He was following directions, his thumb was still firmly over the end of the tube.

|

|

|

Re: Share your gin-pole systems.

[Re: Don P]

#22863

02/28/10 03:29 PM Re: Share your gin-pole systems.

[Re: Don P]

#22863

02/28/10 03:29 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Interesting ratios, Don.

It should be no longer than 60 times its minimum thickness.

A usable rule is to allow 5 feet of pole for each inch of minimum thickness.

These both come out the same, I had to actually run the numbers.

If when leaning the pole one must ensure the base is well anchored. I was adjusting a pole once, moving it from one side of the building to the other, without taking it fully down, it was snowing and the deck was a little slick, coefficient of friction pops it head up, and down the pole goes, the base slipping out from under. It was like a slow motion movie, and nothing you could do but get out of the way. It was mortice and tenoned into an 8x8 as the base and this is fastened down in numerous ways to the floor, which was undone to move the pole.

Yup, when using water levels watch out for kinks, feet standing on the hose, rocks which can pinch the hose, the bucket running out of water, and items mentioned above, etc.

Tim

|

|

|

Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22864

02/28/10 04:00 PM Re: Share your gin-pole systems.

[Re: TIMBEAL]

#22864

02/28/10 04:00 PM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

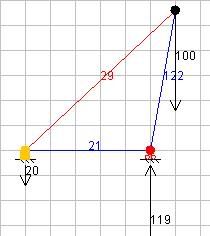

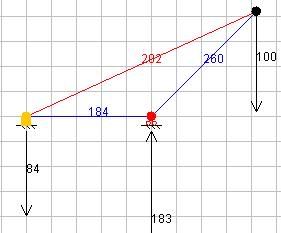

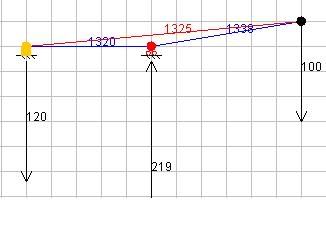

I was curious and thought of one way to play with the angles of the pole to see what the forces do, look at what happens not only to the pole but also the guys and anchors, pretty impressive.    Another ratio that comes to mind, in the NDS "the slenderness ratio for solid columns shall not exceed 50 except that during construction l/d shall not exceed 75." The rapid stress increase when the gin pole is lowered kind of makes me think the angle changed between Craig's lifts but it also made my mind wander, perhaps down a rabbit hole. Dry timber is roughly twice as strong as green but I also know the supple strength of green timber. Load goes to stiffness. There is nothing tougher than a dry knot and this is also the location of weakness. In a green, softer, timber does the stress flow around defects more uniformly?

|

|

|

Re: Share your gin-pole systems.

[Re: Don P]

#22880

03/01/10 06:04 PM Re: Share your gin-pole systems.

[Re: Don P]

#22880

03/01/10 06:04 PM

|

Joined: Oct 2007

Posts: 112

Waccabuc

Member

|

Member

Joined: Oct 2007

Posts: 112 |

Don, Concisely put. May I, with your permission, copy and paste and print this for my own use as a guide to setting up my gin poles? I'll put your name at bottom as author if you wish. I've never used a gin, have so far hung a block to an adjacent building (sometimes w a mast/pole fixed to it) or a nearby tree. Also attached a block to the forks on a all-terrain telescoping forklift. We always set up guy ropes and holdback ropes. I've raised more blown over trees than I have buildings with ropes and snatch blocks, comalongs etc. Always w the fallen tree re-raising I climbed nearby tree(s) to hang a snatch block and sometimes tie guy ropes to the "gin tree". I've raised fallen live trees 20' - 90' tall. Most are in wet ground or on ledge so the roots can't hold in the wind or heavy snow. Gotta make safety/strength judgement on the "gin tree", figure what angle I can get and where the lift point on the fallen tree will help most with the overall balance of of the load. Buckingham Co makes top quality snatch blocks and rope handling tools for arborists. I've gotten some other good rigging rules and diagrams from the Crosby Company catalog and booklets. Grainger used to sell Crosby (made in USA, tested, rated and guaranteed) shackles, turnbuckles, eyebolts, threaded eyes, snatch blocks, wire rope clips etc, but they switched to unbranded mostly chinese imitations of noticeably lower quality. I returned the offshore junk to Grainger and found a distributor for Crosby products in Oklahoma. Crosby also has good training and safety literature. www.thecrosbygroup.comRooster, I like your simple design and clear picture of the rope bullhook. Do you have rights to its design? Is it OK for me to have some made for my own use? Steve

Shine on!

|

|

|

|

|