|

parbuckling

#11120

04/15/07 03:44 AM parbuckling

#11120

04/15/07 03:44 AM

|

Joined: Aug 2006

Posts: 242

timber brained

OP

OP

Member

|

OP

Member

Joined: Aug 2006

Posts: 242 |

More and more, I try to make it possible to raise my frame by hand, partly because of the cost and damages of bringing a crane , and also because I am a traditionalist, and also beacause it just plain sounds fun to do.. I have reduced the size of my design and complexity of my frame and it now seems quite feasible to collect enough people on a select few days to raise this modest 20 by 30 frame. The 2 full length 30 foot plates seem to be the most difficult part of the assembly . The height at the eaves is 12 feet from the bottom of the subsill so I am not sure exactly how one would go about getting this full length plate up and fitted into the roughly 12 foot tall post tops. I recently came across a technique in an article by Jack Sobon in the green guild book called parbuckling which spoke of a way of raising the top plate up on top of these extended posts. It seemed that there was some rigging attached to the post tops and the plate was somehow pulled up to the top. I am quite confused as the there was not enough detail in the writing or the photo to understand it fully.It seems this would put a lot of stress on the tiebeam -post connections as you are lifting up the plate? I really would like to find a way to raise my frame without stressing the connections and members too much as I hear that much damage can be inflicted during the raising. Perhaps if I strap the bents well at these connections the stress would be minimal? Can anyone elaborate or explain this parbuckling technique more fully? Also does anyone have any other tips or tricks for raising by hand that might help me to develop a better script for my own barn-frame raising? Just in case it helps, the frame is a simple 20 by 30 foot english barn style frame with 12 foot eaves height, 1-2 post extension above the tie beam,12/12 pitch, 20 foot clear span on the 3rd of four bents spaced at 10 feet on each bay, collar ties only on the end bents, with principal- common rafter pairs ,no ridge beam. Thanks. Always appreciative of the wiser. tb

|

|

|

Re: parbuckling

[Re: timber brained]

#11122

04/15/07 05:38 PM Re: parbuckling

[Re: timber brained]

#11122

04/15/07 05:38 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

Perhaps you are refering to the idea of running at least two ropes down from the post tops, under the top plate, then back up to the top to a come along or several strong hands. The plate rolls its way up the sidewall, could be tied off at any point. Maybe you would need 4 ropes for your 30 footers...

|

|

|

Re: parbuckling

[Re: timber brained]

#11126

04/15/07 09:56 PM Re: parbuckling

[Re: timber brained]

#11126

04/15/07 09:56 PM

|

Joined: Jul 2006

Posts: 26

Mad Professor

Member

|

Member

Joined: Jul 2006

Posts: 26 |

How about using two gin poles and a couple of block and tackles?

|

|

|

Re: parbuckling

[Re: Mad Professor]

#11132

04/16/07 12:51 PM Re: parbuckling

[Re: Mad Professor]

#11132

04/16/07 12:51 PM

|

Joined: Aug 2006

Posts: 242

timber brained

OP

OP

Member

|

OP

Member

Joined: Aug 2006

Posts: 242 |

I am uncertain of how to construct a proper gin pole and was half hoping that with enough people , it might be unnecessary. Mark, how exactly are these rope lines attached to the post tops? does it seem to you that it may stress the assembled tying joints? Just the basic rope ratchet puller would be suffice or better to use a hand cranked winch? Thanks for the input .

|

|

|

Re: parbuckling

[Re: timber brained]

#11140

04/16/07 03:02 PM Re: parbuckling

[Re: timber brained]

#11140

04/16/07 03:02 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

I've never tried to lift a timber like this, I imagine the ropes would be attached to the tiebeams, then run over the tops of the posts.... There has got to be an interesting moment when the timber comes to the top??? how does it get over onto the post top tennons??? perhaps a strong 2x piece need to be nailed on the inside of the post???

|

|

|

Re: parbuckling

[Re: Mark Davidson]

#11142

04/16/07 05:49 PM Re: parbuckling

[Re: Mark Davidson]

#11142

04/16/07 05:49 PM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

How much do you estimate each plate weighs? How have you lifted so far when cutting the joints?

|

|

|

Re: parbuckling

[Re: DKR]

#11143

04/16/07 07:46 PM Re: parbuckling

[Re: DKR]

#11143

04/16/07 07:46 PM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

Seems to me like you'd want to build a 2x ramp to attach to your posts to pull them up, much like the loggers use to load their trailers.

|

|

|

Re: parbuckling

[Re: DKR]

#11144

04/16/07 08:17 PM Re: parbuckling

[Re: DKR]

#11144

04/16/07 08:17 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Depending on the size and weight of the plate you may be able to get away with one gin pole. We built one here and then built a windlass to wind up the rope. Works great, here is a shot of just the gin pole with two 8x8x16' timbers weighing 500 lbs total:  Here is a shot of the windlass (wooden winch):  Here is a helper tailing the line:  With this setup, I was able to pick up these two timbers totaling 500 lbs with one hand on the handle of the windlass and one hand on the camera to take a picture:  The load was 500 lbs, the blocks had four pulleys in them so the mechanical advantage was 4 to 1 so 500 / 4 = 125 lbs going to the windlass. The windlass mechanical advantage is based on the diameter of the drum vs the diameter of the circle at end of the handles (if I understand it correctly). Which is 13.5 to 1. So 125 lbs / 13.5 = 9.25 lbs. There are four handle ends so 9.25 lbs / 4 = 2.31 lbs if four people were turning the windlass. So alone, I only had to push one handle about 10 lbs pressure to lift 500 lbs of timbers. Works for me..... These are small enough to be transported around to different sites for raising frames..... Jim Rogers Have gin pole and windlass and will travel.....

Whatever you do, have fun doing it!

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#11146

04/16/07 10:23 PM Re: parbuckling

[Re: Jim Rogers]

#11146

04/16/07 10:23 PM

|

Joined: Jul 2006

Posts: 26

Mad Professor

Member

|

Member

Joined: Jul 2006

Posts: 26 |

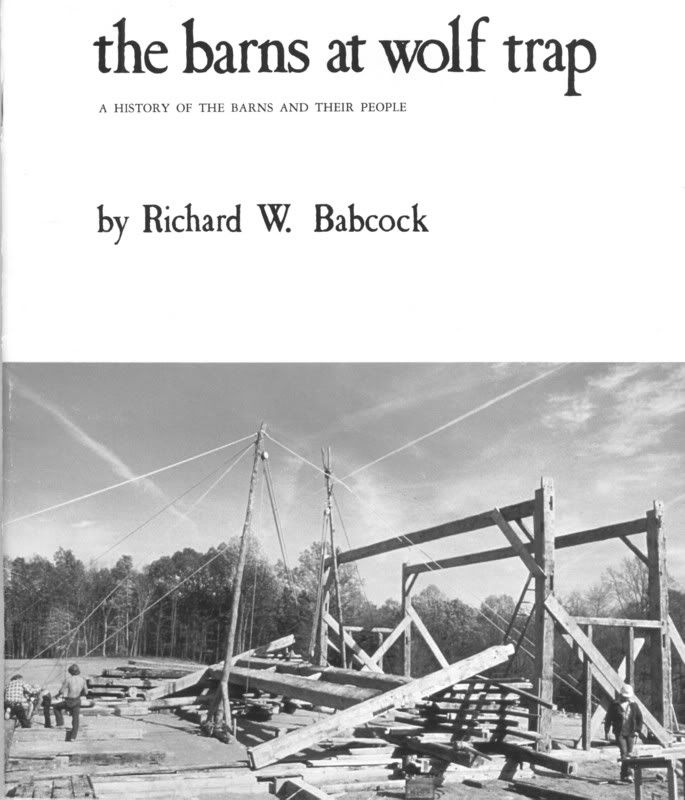

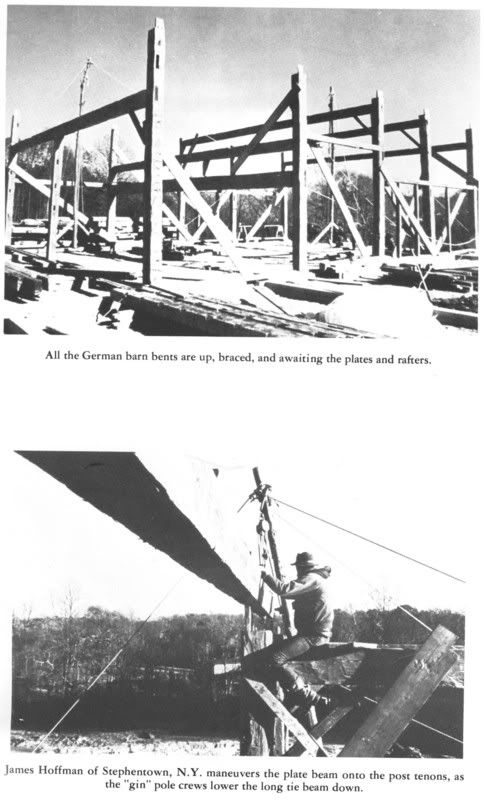

Nice setup Jim. The loader makes a nice portable "base of operations" for the gin pole! I've got some pictures I scanned of a little bigger stepup. The following are from a book "The Barns at Wolftrap" by Richard Babcock. He and his crew dismantled, moved and restored two huge barns all using only a gin pole for lifting. (Richard was kind enough to allow me to scan/post these as long as he was given proper attribution).

|

|

|

Re: parbuckling

[Re: Mad Professor]

#11147

04/16/07 11:48 PM Re: parbuckling

[Re: Mad Professor]

#11147

04/16/07 11:48 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

He inspired me to build my gin pole and windlass.....

All my gin pole and windlass designs were reviewed and approved by Jack Sobon....

Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#11148

04/17/07 12:49 AM Re: parbuckling

[Re: Jim Rogers]

#11148

04/17/07 12:49 AM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

Parbuckling is pretty easy and you could certainly get a 30' plate up to where it needs to be. Bents are all raised and braced. Put planks across tie beams to stand on. Run a separate rope through the tenon hole on the top of each post. Tie a knot. The rope is fixed at the top now, runs down under the plate, and back up to 2-3 people on each rope. Everyone pulls, the plate rolls up the rope, you sit it on the tenon shoulder, untie ropes and all is good. I have some pictures but no time to post them.

Brad

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#11213

04/24/07 01:07 AM Re: parbuckling

[Re: Jim Rogers]

#11213

04/24/07 01:07 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

Member

|

Member

Joined: Mar 2002

Posts: 1,198 |

Just a comment

The long plates were raised vertically in a horizontal position up the vertical end posts using ropes over the tops of the posts, and man power underneath. Men with pike poles would push and lift, and other men on the ropes would hold. near the top the plate would be rested on round pins driven into predrilled 2' holes. Many men then would be assembled on tempoaray scaffolding to lift the plate straight up and then let down over the tenons, fitting in the braces in the process.

NH

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#11214

04/24/07 01:09 AM Re: parbuckling

[Re: Jim Rogers]

#11214

04/24/07 01:09 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

Member

|

Member

Joined: Mar 2002

Posts: 1,198 |

Just a comment

The long plates were raised vertically in a horizontal position up the vertical end posts using ropes over the tops of the posts, and man power underneath. Men with pike poles would push and lift, and other men on the ropes would hold. near the top the plate would be rested on round pins driven into predrilled 2' holes. Many men then would be assembled on tempoaray scaffolding to lift the plate straight up and then let down over the tenons, fitting in the braces in the process.

NH

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#13545

12/15/07 12:16 AM Re: parbuckling

[Re: Jim Rogers]

#13545

12/15/07 12:16 AM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Jim, Did you use any references for your designs for the windlass and ginpole. I don't know much about them but would like to learn and eventually build and use one.

As for your ratios, If you make the drum smaller in diameter and the handles radiate further do you get a better lift ratio?

Thanks, mo

|

|

|

Re: parbuckling

[Re: mo]

#13553

12/15/07 10:18 PM Re: parbuckling

[Re: mo]

#13553

12/15/07 10:18 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Mo:

I discussed all designs with Jack Sobon before I built them.

The gin pole is a direct copy of the ones from Richard Babcock's book. The windlass was a direct copy of one from another book that Jack Sobon showed to me.

It is my understanding that you divide the diameter of the circle created by the end of the handles by the diameter of the drum to get the ratio. So if you decrease the size of the drum you would increase the ratio. But there is a trade off in doing that. The circumference of the drum gets smaller too. That means you'll wind up less line with a smaller drum.

We found this to be a problem when we used the windlass to pull parts of a covered bridge out of a river in southern NH. The block and tackle setup was three pulleys in one block and two in the other. That makes it a 5 to 1 ratio. So with 1 hundred pounds of pull out of the block you could lift 500 pounds of bridge. But the line moves very slow and not very far because it had to go through all the pulleys.

I just measure my drum and it is 7" in diameter and the handles are 98" long so that's a 14 to 1 ratio.

In the pictures I posted above, I was lifting two 8x8x16 timbers. They were eastern white pine, and not green but not dry. I figured they weighed about 249 lbs each. 249 x2 = 498 lbs. Going through my blocks, which are two pulleys each the ratio is 4 to 1. So to lift 498 lbs I need to pull the line at 124.5 lbs. Connecting the line to the windlass reduced the force by 14 so 124.5 / 14 = 8.89 lbs. Very easy to try the windlass at about 9 lbs pressure.

Now someone told me to add a friction drag load to the total due to the line going through all the pulleys. And that this load could be as much as 40% of the total loads. So doing the numbers again 498 x 40% = 199.2 -- 498 + 199.2 = 697.2 / 4 = 174.3 / 14 = 12.45 lbs. Again very easy to turn the windlass at 12.45 lbs of pressure. I actually lifted both beam by turning the windlass with one hand on one handle, and I took a picture of the timbers up off the sawhorses with the other.

And if you wanted to break it down even further and use all four handles with four people that would be 12.45 / 4 = 3.1125 lbs of force on one handle.... Very easy for about anyone to turn.

I was told to only lean the gin pole off of vertical not more than 20°. But in the picture I posted we let it lean way over. This was intentional as we were trying to break something to see if it would fail. I wanted it to break here in my yard where no-one could get hurt if it was going to break, instead of on raising day with the crew all around the frame.

We put twice the intended load on the setup and it didn't fail.

We used it to raise a frame here in my yard one day, and it worked great.

If you need any more info please feel free to ask, and if my numbers or assumptions aren't correct, please let me know.

Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: parbuckling

[Re: Jim Rogers]

#13558

12/16/07 04:01 PM Re: parbuckling

[Re: Jim Rogers]

#13558

12/16/07 04:01 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Jim, A couple of questions since you offered. Thanks.

Are there any sizing parameters for the gin pole depending on length and wood species.

What type of line did you use for the guys (I think that is the right term?) Those are anchored to your machine right?

And lastly, Does the ginpole have to be set perpendicular to the pieces placement and does it also have to have the block and tackle directly plumb over its placement too? The angle of the gin pole is not suppose to move right?

Thanks, mo

P.S. Great thread, Cranes can't get everywhere.

Last edited by mo; 12/16/07 04:04 PM.

|

|

|

Re: parbuckling

[Re: mo]

#13562

12/18/07 12:14 AM Re: parbuckling

[Re: mo]

#13562

12/18/07 12:14 AM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Are there any sizing parameters for the gin pole depending on length and wood species?

Well, we just used what we had on hand, which was eastern white pine. But to be technical you should figure out what your heaviest load would be and make sure a column or post of the size and type that you want to use will hold up that load. Probably strength parallel to grain psi value from the NDS or something like that. What type of line did you use for the guys (I think that is the right term?) Those are anchored to your machine right? In the failure test, which is the pictures I posted, yes the guy lines are attached to the backhoe fork attachment hooks, as well as the back line. These small white pieces of rope are actually one long piece that I made a loop in at the middle point so that I didn't have to cut it and it would be as long as possible. This was so that I could tie them off to other solid objects depending on the actual location where the gin pole was going to be used. This/these lines are 3/8" braided nylon. And lastly, Does the ginpole have to be set perpendicular to the pieces placement? No, I don't think so, but it does help it to remain stable as the upside down "T" base prevents it from shifting/leaning side to side. ....and does it also have to have the block and tackle directly plumb over its placement too? We did this so that when you lower the piece you don't have to swing it out or in to line it up over it's intended location. The angle of the gin pole is not suppose to move right? When I discussed this with Jack Sobon and the methods he used to raise his own side entry English barn, I asked him how he did it alone. He told me that he put a peg in his gin pole so that when his timber was raised up as high as it needed to go he could tie off his lift line and it wouldn't allow the timber to come back down. He also had a "safety line" that when from the top of the gin pole opposite the back line, tied off to something solid on the other side of his yard. This was to prevent the gin pole from going over backwards if the load shifted when fully raised. This seemed like a great idea to me as you are raising the center of gravity of the whole rig when a timber is up there. He aligned his gin pole to be outside of his building and the lift block was not over the wall posts. After he raised his plate to the top he adjusted his back line and side guy lines to allow the gin pole, and plate to lean in over the post's top tenons. Then with a tag line on one end of the plate, to help guide it, he lowered the plate until the lower end was sitting on the tenon. He then re-tied the line off to the peg in the gin pole and went up his ladder to adjust the plate's alignment to the first post top tenon. Once this tenon was engaged into it's mortise he lowered the plate some more. We usually have the lift point of the plate just off center a fraction so that one end will hang a little lower then the other end so that we can start with this low end to insert it's mortise onto the corner post's top tenon. Then that post's brace, then the next post down the wall and end with the last post or other end of the plate engaging the other corner post. This way you're not trying to align all post tenons and all brace tenons at once. Now this isn't much but just enough so that you can do this safely and easily. By the way good questions. Jim Rogers

Whatever you do, have fun doing it!

|

|

|

|

|