|

tie

#14435

02/28/08 05:27 AM tie

#14435

02/28/08 05:27 AM

|

Joined: Nov 2006

Posts: 850

mo

OP

OP

Member

|

OP

Member

Joined: Nov 2006

Posts: 850 |

I recently saw a "tie" that was two different sticks (king post). I thought that the rafter thrust on the connections below would create tension on the "tie". How do you have a tie that is two different pieces withstand tension?

|

|

|

Re: tie

[Re: mo]

#14462

03/05/08 03:04 AM Re: tie

[Re: mo]

#14462

03/05/08 03:04 AM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

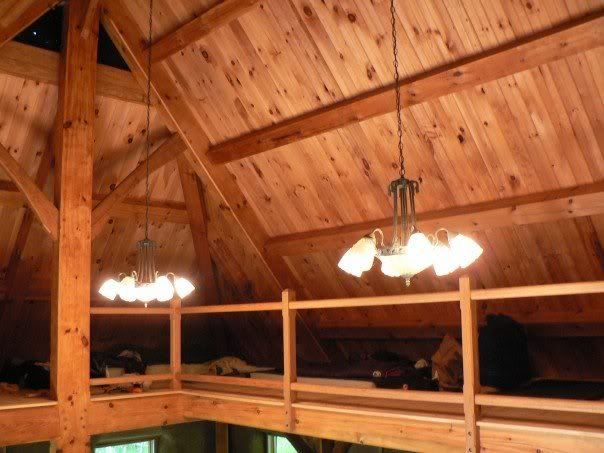

Simple... shouldered and pegged. Or two half dovetails... Steve Chappell does it quite often I believe. This is the Library loft at Fox Maple. I can't remember if this is half dovetailed or not, but you can see the shoulders and pegs.

I cut it twice, and it's still too short!!

|

|

|

Re: tie

[Re: CarlosCabanas]

#14465

03/05/08 01:21 PM Re: tie

[Re: CarlosCabanas]

#14465

03/05/08 01:21 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

That looks like a posted ridge -- so there wouldn't be any tension in the "tie". If you are clear spanning with a truss, the situation is different.

It takes an extremely serious scarf to join a tie beam for a truss of any size. We built some 36' kingpost trusses recently (with a continuous tie) and under design loads there is 15,200 lbs of tension in the bottom chord. And we don't have any snow loading to speak of here.

One way you could do it is a really long (maybe 4 feet or longer) tabled scarf with shear blocks or split rings. But to deal with 15.2 kips you will need 3 or 4 shear blocks and enough of a shear plane between them to develop enough capacity. It takes through bolts or steel bands to keep the pieces clamped together tightly.

Maybe some of the bridge guys can dig up a photo of a bottom chord scarf (Will - are you out there?).

|

|

|

Re: tie

[Re: Gabel]

#14468

03/05/08 02:31 PM Re: tie

[Re: Gabel]

#14468

03/05/08 02:31 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

Not exactly sure what a posted ridge is, but Carlos picture shows a kingpost with split tie beam. The very bottom of the king has a pendant (not a post) which is just out of range of the picture shot. I was there when he took the pic. The kingpost truss spans the width of the library. What you also see in the pic is a small partial perimeter loft framed by a couple floor joists. The center of the building is left open to the ceiling.

Steve showed us how this was possible so that you didn't need really long tie beam timbers. Of course you always have to work out all the loading and stresses, like on any design to be sure it is strong enough with enough margin of safety.

Last edited by brad_bb; 03/05/08 02:34 PM.

|

|

|

Re: tie

[Re: brad_bb]

#14470

03/05/08 02:48 PM Re: tie

[Re: brad_bb]

#14470

03/05/08 02:48 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

That roof of the library building is thatched and is something like a 14/12 pitch.

I have photographed that king post also....

Whatever you do, have fun doing it!

|

|

|

Re: tie

[Re: Gabel]

#14478

03/05/08 05:28 PM Re: tie

[Re: Gabel]

#14478

03/05/08 05:28 PM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

That looks like a posted ridge -- so there wouldn't be any tension in the "tie". If you are clear spanning with a truss, the situation is different. As brad stated that is a clear span with a pendant. Sorry it is the only picture I had available. I don't understand why you would state that there is no tension as it is a post!! There would still be tension as the rafter feet push outwards even if it is on a post. A post holding a king post would be rather redundant(depending on sizes of timbers and loads) as the king post actually pulls/holds the tie beam upward. Carlos

Last edited by CarlosCabanas; 03/05/08 05:30 PM.

I cut it twice, and it's still too short!!

|

|

|

Re: tie

[Re: CarlosCabanas]

#14479

03/05/08 06:03 PM Re: tie

[Re: CarlosCabanas]

#14479

03/05/08 06:03 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

I thought the kingpost was a ridge post, running from the floor to the peak and holding the ridge up since that is what it looks like in the picture. If that were true then the rafters would not be pushing outwards. If the top is held up, the only load at the feet is vertical.

What is the span of that building?

|

|

|

Re: tie

[Re: Gabel]

#14480

03/05/08 06:11 PM Re: tie

[Re: Gabel]

#14480

03/05/08 06:11 PM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

Sorry I'm not great at estmating distances... somewhere between 20 and 30 feet...

Yes I agree a ridge post would eliminate a lot of the horizontal thrust... somehow that skipped by....

Carlos

I cut it twice, and it's still too short!!

|

|

|

Re: tie

[Re: mo]

#14506

03/07/08 02:05 PM Re: tie

[Re: mo]

#14506

03/07/08 02:05 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Mo, Here is an awesome tension scarf in a bottom chord of a bridge. Photo by Will Truax -- Will, I hope you don't mind my posting this again.

|

|

|

Re: tie

[Re: Gabel]

#14530

03/08/08 08:33 PM Re: tie

[Re: Gabel]

#14530

03/08/08 08:33 PM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Gabel - don't mind at all, I posted it for folks to see.

I missed this initial call to arms. I must admit, sometimes I don't wade through all the chatter.

And as you suggest snowload is a huge factor in these calcs, I live about an exact hour southwest of Fox Maple Land and the GSL in my town (assigned town by town here - highly variable with differences in proximity to the coast and elevation - This years huge accumulation may have the powers that be re-accessing those assignments as was done after the last such winter which saw collapses) is 95 lbs psf

Brad - you suggest "Steve showed us how this was possible so that you didn't need really long tie beam timbers"

Would you elaborate please.

I'm asking for two reasons - I'm curious to learn as to how...

But perhaps foremost, I'm also concerned that someone could view this thread, and attempt to build a clear span King Post in the configuration pictured and that IMO, holds the potential for disaster.

|

|

|

Re: tie

[Re: Will Truax]

#14531

03/08/08 10:47 PM Re: tie

[Re: Will Truax]

#14531

03/08/08 10:47 PM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

Brad's statement was in reference to the evolution of timber framing. As longer timbers diminish in availablity, (Something that happened in Europe and is slowly happening in North America)one must find ways of spanning distances, without timbers long enough to span them... the evolution of the hammerbeam if I understand correctly.

I do remember Steve Chappell saying that god makes the best scarf joints (in other words any full length timber will always be stronger than a scarf joint) and he stated often that he liked to build frames with only compression joints and no tension joints.

As I have stated I can't remember for sure if the king post that I posted a picture of is a half dovetail or not. However I would be very suprised, based on Steve's overall philosphy of Timber framing if it were not a dovetail. Having said all this I don't think I have as much knowledge of timber framing that Steve posesses in his little pinky.

Carlos

I cut it twice, and it's still too short!!

|

|

|

Re: tie

[Re: CarlosCabanas]

#14541

03/09/08 11:56 AM Re: tie

[Re: CarlosCabanas]

#14541

03/09/08 11:56 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Steve C. used 2 wedged half dove tails. Tim

|

|

|

Re: tie

[Re: TIMBEAL]

#14619

03/13/08 03:33 AM Re: tie

[Re: TIMBEAL]

#14619

03/13/08 03:33 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Tim - Thanks, I knew that this had to be wedged dovetail tenons, but since there was no telltale details in the the photograph, I thought that just needed to be clarified, on the off chance...

Carlos - Thanks also for your reply - and while yes, like Europe of say some five hundred years ago the eastern US was once largly denuded (the late 19th & early 20th centuries) and timber of length was in scarce supply, This is simply no longer the case, stems grow longer every day, and while the market for long timber is still underserved, this too is reversing. Long timber can be had if it is desired.

Before I learned that I could purchase any length likely necessary to residential design just forty or so miles away, (closer still now) I bought sawlogs of my needed lengths from local loggers and hewed what I needed.

One needn't necessarily - find ways of spanning distances, without timbers long enough to span them...

Finding the lengths necessary is a real and viable option, nor does it necessarily require trucking from distance.

I've spoken to this in previous posts, so I will not wax on about seldomn scarfing anything or almost always designing with continuous ties and plates...

|

|

|

Re: tie

[Re: Will Truax]

#14622

03/13/08 08:25 AM Re: tie

[Re: Will Truax]

#14622

03/13/08 08:25 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Will, I have only to travel 100 feet to the mill, where I can saw up to 70'. The issue is getting the log to the mill, the loggers chuckle when I ask for some long sticks, or crooked pine from the wolf/cabage pines. Tim

|

|

|

Re: tie

[Re: TIMBEAL]

#14629

03/14/08 12:01 AM Re: tie

[Re: TIMBEAL]

#14629

03/14/08 12:01 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Tim, you mean like this ???  This guy didn't chuckle, when at the landing they pointed at this log in a pile with others like it, at what he saw as a pile of slash... He literally refused to truck it the first time, I believe he was quoted as saying - " Therah is simply, no way possible, therah, is any carpentah, anywerah, crazy enough to want that useless pile, 'a blankin bug food" Natty curves are a whole different level on the matrix of timber supply. Once foresters and loggers learn mills want something longer than standard lengths, they're happy to supply them - The out of the norm, unstackable, slightly outside the market (touched timberframer) aspect of dealing with crooks and curves, sometimes makes them see dollar signs - and that, from the chipper bound slash pile (Think of the beautiful curves spit into the air every day) that really aren't there. The trick I think, is to make it as easy as possible on their end. Have them just put candidates aside to then inspect and purchase, and maybe even arrange trucking yourself, so the time spent unloading your "wierd load" doesn't knaw at the back of their heads with how much more they could be making if that knuckle boom were swinging real logs at a real mill. Like long stuff, it is in part, about that end of the market understanding that this end is here and in numbers where the market can no longer be called "niche".

Last edited by Will Truax; 03/14/08 12:38 AM. Reason: vertical curve

|

|

|

Re: tie

[Re: Will Truax]

#14631

03/14/08 08:29 AM Re: tie

[Re: Will Truax]

#14631

03/14/08 08:29 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Will,

What would you do with the above crooked log ?

Break it in two and make 2 pairs of large arch braces ?

What about the reaction wood locked up inside ?

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: tie

[Re: Ken Hume]

#14650

03/17/08 04:31 PM Re: tie

[Re: Ken Hume]

#14650

03/17/08 04:31 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

Make it a cool looking post in the middle of a frame! like a center post in the center of a house on one side of a great room, how about that? It sure would be interesting to see. You'd have to keep it whole of course(debarked).

Last edited by brad_bb; 03/17/08 06:07 PM.

|

|

|

Re: tie

[Re: brad_bb]

#14652

03/17/08 08:31 PM Re: tie

[Re: brad_bb]

#14652

03/17/08 08:31 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Bug wood. It looks like that one is on the way to the bugs already. I had a buggy wood frame that went up, and after the heat came on in the late winter they started chew-chew-chewing, the little slivers falling out the holes, eventually out came the adults! I took in a live trap as a joke, had to lighten it up a bit. The worms are as big as my little finger. I found compressed air worked well, a bit messy. Some of the adults popped out not quite done and kind of translucent and resembling something out of a si-fi movie.

Nice cruck, I would cut it in half and get 2 sticks as Ken mentioned. It must be 25-30' as it hangs off the bed of the truck. Almost big enough for book matched pairs, 4 pieces. It all depends on its final use. I have a shot of a simular piece but taken from the operators chair. They don't stack well on the truck, lots of air.

I have found if they go into the frame wet you will get some gaps as it dries. I am now trying to let them dry for a while in the sawn stage and cut a bit longer than the intended use (with angles cut) than cut the joint just before raising.

TTRAG was great, I'm a bit wiped out and now need to rest so I can go back to work. I was seeing Fore Bay barns in my sleep. Tim

|

|

|

Re: tie

[Re: TIMBEAL]

#14704

03/21/08 12:05 PM Re: tie

[Re: TIMBEAL]

#14704

03/21/08 12:05 PM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Ken - That stick went into a colleague's frame which I nick-named the "Hex-o-Cruck" I put up the above picture and one of the frame a year ago now - http://www.tfguild.org/forums/ubbthreads...h=true#Post5791It was bookmatched, and they were used a set of 'modified' arched braces. I'll put up another when I get home, stay tuned for scribe - The tension wood issue (at least in EWP) hasn't been as great as I'd expected - have only found one piece ever, unuseable. As Tim suggests - Dry is in part how to achive stability, starting with winter cut it drys in small scantling (most braces)in a season. Tim, agreed TTRAG was a hoot, and it's always good to put another face to a name.

|

|

|

Re: tie

[Re: Will Truax]

#14925

04/04/08 08:08 PM Re: tie

[Re: Will Truax]

#14925

04/04/08 08:08 PM

|

Joined: Aug 2006

Posts: 242

timber brained

Member

|

Member

Joined: Aug 2006

Posts: 242 |

Will. I have difficulty finding timbers in lengths greater than 18 feet. Do you have any tips on how one would go about sourcing long timbers or even logs that could be hewn? I find my self in design work, being limited in creativity by the lack of sources for long continuous timbers. Most of the time the dimensions needed are 8" x 10" , so theses need not be gargantuan trees they are milled from. The few loggers and sawyers that I know, chuckle and see dollars when I mention my intent on using continous timber lengths. By the way I love that saying " that God makes the best scarf". tb

|

|

|

Re: tie

[Re: timber brained]

#14937

04/05/08 11:45 AM Re: tie

[Re: timber brained]

#14937

04/05/08 11:45 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

timber brained, my experience with the loggers has been good. If you treat them well they will treat you well. I keep in mind they are out to make a living and it is expensive and dangerous work. When cutting long stock they have numerous grades in that log. The butt could be of a high grade worth more than the rest of the whole log. But you need that high quality 12' log included to make the length. So you pay the price and are content, well the client pays in the long run. It just cost more to handle long sticks, and the benefits are worth it. On the other hand how much time is used in the extra joinery of splicing and interupted top plates? Maybe they are even more cost friendly than first thought. Do a cost comparison and include the freedoms given of the longer stock. Long sticks are an open door. Tim

|

|

|

Re: tie

[Re: TIMBEAL]

#14947

04/05/08 10:00 PM Re: tie

[Re: TIMBEAL]

#14947

04/05/08 10:00 PM

|

Joined: Jan 2008

Posts: 16

gregk

Member

|

Member

Joined: Jan 2008

Posts: 16 |

My experience with getting a long log cut was frustating. I had some beautiful tall, straight tulip poplar. Log buyers did not want them, no market in this area. Not that there is a market for much these days. The Amish do most of the log work here on the Ohio/PA border. They keep most of it for use in their community. Hemlock is "gold".

I found an old-timer who was running a mill behind his house, an old Frick mill. He claimed he could cut a long log but when it came down to it he said it was "a lot of monkeying around". So that meant that I had to push him a bit. Had to get involved in the process. Like suggest taking out a wall of his enclosure, and bringing some help over and my tractor with loader. He gradually came around and was "sold" once he saw I was serious about it. And that being off by a 1/4" was not a big deal. Actually think that he had trouble even thinking "long" because there is so little call for it these days. He would gladly do it again. He gets paid by the bd ft. As long as I helped move the material around, he was happy.

Hauling these logs was a challenge as well. Some had to be lifted one end at a time. 35' was about the longest we handled. The distance to the mill was only a few miles so we only ran on improved roads for a bit.

The economy being what it is, it would seem to me that there would be some interest in "fooling around with these logs if you looked for the "little guy".

Greg

|

|

|

Re: tie

[Re: Will Truax]

#14980

04/07/08 08:49 PM Re: tie

[Re: Will Truax]

#14980

04/07/08 08:49 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

Will Truax,

This is in response to you question on page 1 of this post.

Steve illustrated that the kingpost frame is probably the most effecient use of timber for the given space. The original pic that Carlos posted is a kingpost that makes up the library at Foxmaple in Brownsfield, ME. His primary example was his timberframe workshop which is a 32foot clearspan kingpost. If I remember it is 3 clearspan kingpost bents and the 4th a conventional bent. The king post will allow you to span these distances using shorter timbers (you don't use a continious tie beam. The only downside is tension joinery, which can be used if propely engineered, just not preferable. By not preferable does not mean that it can't or should not be used, just that if there is a choice, try to use compression as a it will always be stronger in compression. Steve actually worked through stress calculations in both the kingpost and a regular joint to show the difference. More focus should be given to design of tension joinery, the selection of material, and the execution of the frame pieces (and proper support during raising) as there is typically less margin than a compression frame. One question I currently have is whether such a kingpost frame can adequeately support the extra load of a second floor (with sufficient margin of safety) on the king post truss. This must be flushed out by calculation in my opinion.

|

|

|

Re: tie

[Re: brad_bb]

#14983

04/07/08 10:44 PM Re: tie

[Re: brad_bb]

#14983

04/07/08 10:44 PM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

Brad

I've never heard of a "conventional bent" I believe they are all king posts. He may have had one with queen posts but the use of the word conventional risks the start-up of a whole new thread!!

You are worrying way too much about the load carrying capacity of a king post. Stop worrying about it and calculate your load and then the size of the members in consequence!!

Carlos

I cut it twice, and it's still too short!!

|

|

|

Re: tie

[Re: brad_bb]

#14998

04/08/08 10:54 AM Re: tie

[Re: brad_bb]

#14998

04/08/08 10:54 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Thanks Brad & understood.

Do know I was simply working to insure that it was clearly stated in the thread, that such a truss required a well designed tension joint and required very careful planning.

|

|

|

Re: tie

[Re: timber brained]

#15001

04/08/08 11:00 AM Re: tie

[Re: timber brained]

#15001

04/08/08 11:00 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

TB -

Tim has hit the ferrous peg on the head.

Work with them, and work to understand their business. Know how much area mills are paying per thousand, and then expect and be willing to pay a slight premium, you are likely buying clear butts. (and a choice one at that if the stem is strait enough to do what you want) Learn to talk the talk - meaning, work to learn the techno-jargon of both the sawyer and the logger.

Understand that the mans bottom line is based on getting as many loads to the mill as possible in any given day, and that your maybe undersized load (and the extra work putting it together and perhaps the phone call precipitating it) might mean getting one less full load out in a day, be willing to accept yours after hours, make it a bonus and not a pain.

I've gotten calls about one lovely and lonely cruck on a cut, and arranged trucking myself (love ramp truck wreckers - winch it up, dump it off) because it's known a check will maybe appear in the mail for the cost of putting a stem aside at the landing, and making a phone call.

Talk to other area framers, then to foresters, work with both to create a market.

We are fortunate and in a relativly rare position in todays world, where we often work a commodity from it's raw source through to it's end use -

Like beef does not really come from supermarkets on little styrofoam trays, wood products do not really come palletized in big box stores - The consumer is too removed from most of what he uses and how it is made - So too, is the other end of the market from its end user - Like a cowboy rarly shares a smile and a glass of wine with the people who end up buying the finest cut from the beef he knew on the hoof - A logger rarely sees the end use of the tree he knew on the stump...

Invite the man and his people to the raising - make him interested in what you do - Build real working relationships.

|

|

|

Re: tie

[Re: CarlosCabanas]

#15010

04/08/08 08:38 PM Re: tie

[Re: CarlosCabanas]

#15010

04/08/08 08:38 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

I was merely trying to distunguish between the kingpost truss in question and all other bents like queen post, and ones that do not clear span but have posts in king or queen positions. The kingpost is not unconventional per sae. Sorry for the poor word choice. You are worrying way too much about the load carrying capacity of a king post. Stop worrying about it and calculate your load and then the size of the members in consequence!!

I agree totally! I'm working on it, trust me. Just reviewing my statics last night- method of sections and joints, sum of forces and moments equal to zero etc. Been bogged down with plumbing work at my mom's house and my own(farm house).

|

|

|

Re: tie

[Re: brad_bb]

#15244

04/26/08 01:23 AM Re: tie

[Re: brad_bb]

#15244

04/26/08 01:23 AM

|

Joined: Aug 2006

Posts: 242

timber brained

Member

|

Member

Joined: Aug 2006

Posts: 242 |

Thanks for your help and insight with the issue of acquiring lengthy timber. Sorry to temporarily hijack the thread as well. Will, I definitely really relate to your ideas in relation to consumers being so far removed from the nature of products, in all ways. I think you are onto something good when you talk of developing community and understanding between all of the different stages of a project. Around here in my restaurant we have been doing something similar from the local farms to the kitchen and on to the consumers. I would like to develop this in all aspects including my work in timber framing. I think to get some side work in logging and millng to further my understanding and connections to the whole of the trade. Good ideas! thanks again tb

|

|

|

|

|