|

Hello, New Member here

#14822

03/29/08 05:08 PM Hello, New Member here

#14822

03/29/08 05:08 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

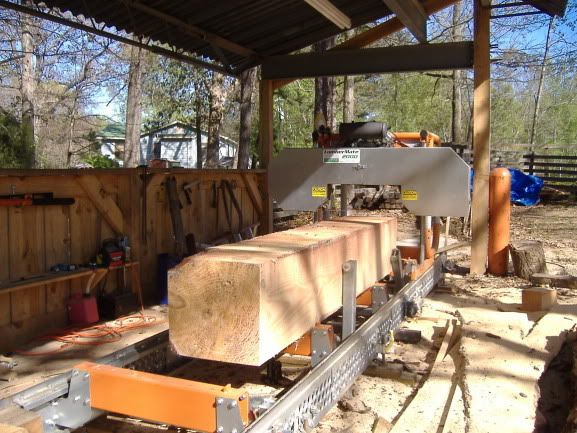

Hi everybody, I'm new here. I have owned a portable sawmill for about two years now. I would love to get into timberframing. I have been planing on sawing out some shop kits for the DIY's around here. I would rather make some timberframe kits. Can you all tell me what tools I should gather first? Also maybe soomeone could point me to a good book or two. Hope to get to know and become friends with many of you all.

Thanks and Have a Great day

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14833

03/30/08 10:48 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14833

03/30/08 10:48 AM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Wow, you guys are just too friendly. Oh well I got along fine before comming here and I'll do just fine Not comming back any more. Most unfriendly forum I've been to yet. Really not even a welcome?

God Bless and Good bye.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14834

03/30/08 01:39 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14834

03/30/08 01:39 PM

|

Joined: Apr 2002

Posts: 895

daiku

Member

|

Member

Joined: Apr 2002

Posts: 895 |

Let's see. You posted at noon yesterday, a saturday, and then at 5am this morning you get frustrated and leave. So you basically gave us half a saturday (during march madness, no less) to reply to your post. This board is not ARWW -- it averages maybe 4-5 posts a day. Lots of newbies get lots of expert advice here, from knowlegeable folks who are generous with their time. Settle down, and try again (without the attidtude). We are a freindly bunch if given a chance. CB.

--

Clark Bremer

Minneapolis

Proud Member of the TFG

|

|

|

Re: Hello, New Member here

[Re: daiku]

#14835

03/30/08 03:34 PM Re: Hello, New Member here

[Re: daiku]

#14835

03/30/08 03:34 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Whatever, 36 views and not one hello or welcome, just chastizing. BTW I don't have any attidtude that I didn't gain from here. And You my friend, just add to it. I asked a simple question and you won't even answer that one question. Thanks for ALL your help.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14836

03/30/08 04:18 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14836

03/30/08 04:18 PM

|

Joined: Dec 2007

Posts: 29

Alpmeadow

Member

|

Member

Joined: Dec 2007

Posts: 29 |

Welcome woodbutcher!

I am a new member of this forum and have been helped (most times) with my posts. I have a woodlot and woodmizer mill and have joined the TFG as a member to learn and experience timberframing. Gotta a long way to go. However if your experience here is not what you want there is another forum which helps newbies like me and this post shows a list of tools, prepared by Jim(who is a great contributor on this forum also).

http://www.forestryforum.com/board/index.php/topic,6403.0.html

I hope this helps

Cheers

alpmeadow

Irv Graham

Alpine Meadows Lodge & Woodlot

Golden BC

2001 Kicking Horse TF Bridge a great experience!

|

|

|

Re: Hello, New Member here

[Re: Alpmeadow]

#14838

03/30/08 07:57 PM Re: Hello, New Member here

[Re: Alpmeadow]

#14838

03/30/08 07:57 PM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

Welcome

i do think you jumped the gun a little. The 36 views may not have even been registered members!! Anyway some say all you need is a mallet and a chisel. Others like to move things along at a more reasonable pace and for that.... Chain mortiser and a larger circular saw are important.. other than that you probably have the rest of the tools nessicary.... framing square, exacto knife.

My favorite book is "A Timber Framer's Workbook" by Steve Chappell

Use the search tool on the forum and you will find a ton of info!!

good luck,

Carlos

I cut it twice, and it's still too short!!

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14840

03/31/08 01:54 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14840

03/31/08 01:54 AM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

Hi there woodbutcher, if you're still there that is... a good tool on the forums is the search engines we have. One is at the top of this page. try searching tools, books or whatever you're interested in, you may find some answers there, as there are many old posts to read through. General questions on books and tools often come up, so everybody doesn't jump in to answer one more.... Another search engine is located here.

Last edited by Mark Davidson; 03/31/08 01:56 AM. Reason: syntax

|

|

|

Re: Hello, New Member here

[Re: Mark Davidson]

#14841

03/31/08 10:52 AM Re: Hello, New Member here

[Re: Mark Davidson]

#14841

03/31/08 10:52 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I am not sure where to start.

I just picked up the guilds green book Timber Frame Joinery and Design volume 2. I particularly liked Sobons tips on short cuts and the bit on sap wood. That is a book. And here is a tool. Stanley's Sharp saw, I call it a shark saw because of the picture on the cover. I will even add a tip too, find one with 8 or 9 TPI. I am not sure why the stores stock the fine ones, I am always grumbling over that. Or a even better saw is the Docking saw, they can't be found new, you need to keep your eyes open as they are elusive but well worth it. Once you have found that saw learn how to sharpen it yourself, don't risk sending it out, and you will learn more by doing it yourself. Where did the green letters come from? Tim

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14845

03/31/08 01:13 PM Re: Hello, New Member here

[Re: TIMBEAL]

#14845

03/31/08 01:13 PM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

You live in the neck of the woods where there are a ton of timber frame companies. You will learn a ton if you sign up for a week-long introductory class. They're going to tell you to bring a 1.5 barr chisel, a mallet, squares, maybe calipers, and pencils. Then after you come home, you'll probably want a 2" chisel, a nice hand saw, and a couple of good planes. You can do a lot of this work without power tools, for example you can use a boring machine to cut the mortices. However, most starting out today buy circular saws, sanders, big drills, planers, etc. Then you'll need straps and rigging to raise your frames. And it's more than just tools. If you are selling these frames to put up most places, your timbers have to be stamped by a grader, and you'll need an engineer stamp for your plans. Sobon and Benson books are where most people start these days. Do an Amazon search. They aren't hard to find.

|

|

|

Re: Hello, New Member here

[Re: DKR]

#14846

03/31/08 01:31 PM Re: Hello, New Member here

[Re: DKR]

#14846

03/31/08 01:31 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

I don't check the boards much on Friday and Saturday due to the low activity. Every body is either getting ready for the wekeend or out doing work already and too tired to check the board on Sat night typically. Makes sense. All I can say is - Wow! I guess he's gone already, so I don't have to welcome him or address his question. Someone with so little patience probably doesn't have the patience for timberframing, eh?

|

|

|

Re: Hello, New Member here

[Re: brad_bb]

#14861

04/01/08 08:36 AM Re: Hello, New Member here

[Re: brad_bb]

#14861

04/01/08 08:36 AM

|

Joined: Feb 2006

Posts: 718

Dave Shepard

Member

|

Member

Joined: Feb 2006

Posts: 718 |

I agree Carlos, the spiders can really rack up the views counts.

The WoodButcher, there are many possible reasons why you did not get an immediate welcome, not worth going into at this point, but don't blame everyone here. This is a great group of people who are very happy sharing any knowledge they have with anybody.

I agree that making timber frame kits for the DIYers is a good idea, something I have been working on for a while now. Why don't you stop back and try again?

Dave

Member, Timber Framers Guild

|

|

|

Re: Hello, New Member here

[Re: Dave Shepard]

#14875

04/01/08 09:15 PM Re: Hello, New Member here

[Re: Dave Shepard]

#14875

04/01/08 09:15 PM

|

Joined: Oct 2002

Posts: 209

Will B

Member

|

Member

Joined: Oct 2002

Posts: 209 |

For a first book, I suggest Jack Sobon's "Build a Classic Timber Frame House" for someone that wants to learn to layout and cut joinery. Tedd Benson's "The Timber Frame Home" for someone more interested in design and systems issues. And of course, the DVD with all the back issues of Timber Framing magazine for everyone! Welcome, Woodbutcher (if you're back).

Last edited by Will B; 04/01/08 09:16 PM.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14878

04/01/08 10:41 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14878

04/01/08 10:41 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Hello to All of you. Sorry for being so impatient in my earlier post. (really) Please Forgive me. I am starting my timberframing of with the sign for my sawmill business. I have never done this kind of work before, but have always been fascinated with TF. My sign post is 8"X8"X12' I am going to use the mill to cut what tenons I can. Mortise's on the other hand, are fun for awhile, but it's a short while lol, I really enjoy it. Can someone tell me how long my tenons should be? I have my first one cut at 2"T X 6"H X 4"L I think it should be longer. Am I right? Was thinking about going all the way thru? BTW It's gonna be a cantalevered sign post with the actual sign hanging from it. Which will be a 3"T X 24W" X 4'L slab of red oak.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14880

04/02/08 12:11 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14880

04/02/08 12:11 AM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

not quite sure of what your plan is for the sign, but if you have a horizontal piece... I wouldn't put the mortises right through as you are just giving water access to more end grain.

Carlos

I cut it twice, and it's still too short!!

|

|

|

Re: Hello, New Member here

[Re: CarlosCabanas]

#14881

04/02/08 01:43 AM Re: Hello, New Member here

[Re: CarlosCabanas]

#14881

04/02/08 01:43 AM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

I'm confused about the design to. Is your sign kinda sorta going to look like a real estate sign. An upside down L with a sign hanging from it?

|

|

|

Re: Hello, New Member here

[Re: DKR]

#14883

04/02/08 09:13 AM Re: Hello, New Member here

[Re: DKR]

#14883

04/02/08 09:13 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

That's what it sounds like to me. I would use rot resistant wood. With a Dutch theme, use a 24" through tenon with a wedge on the out side, and a peg or two. A big tenon like that should be simple on your mill. Stick in a naturaly curved brace for some support of that slab of Oak. The books Will mentioned will be of great help in understanding. Is that Yellow pine? Tim

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14884

04/02/08 09:20 AM Re: Hello, New Member here

[Re: TIMBEAL]

#14884

04/02/08 09:20 AM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Hi All, Yes you are all right about the sign looking like a giant real estate sign. Also that is SYP.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14886

04/02/08 10:03 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14886

04/02/08 10:03 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

How well does SYP hold up to the weather? Does SYP have much of a sap ring? If it does, cut all of the sapwood off your stock. Tim

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14889

04/02/08 03:28 PM Re: Hello, New Member here

[Re: TIMBEAL]

#14889

04/02/08 03:28 PM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

Are there going to be two posts, with a beam between them from which the sign will hang? Or is there only going to be one post with a beam from which the sign hangs? I had tought the latter, but if that's it, then I don't understand why you've cut two mortices.

|

|

|

Re: Hello, New Member here

[Re: DKR]

#14890

04/02/08 04:49 PM Re: Hello, New Member here

[Re: DKR]

#14890

04/02/08 04:49 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

It's like a hammer beam. Lower mortise is for the brace, upper mortice is for the hammer beam. The sign hangs off the end of the hammer beam. The hammer beam has a tenon that goes in the post, and a mortice for the other end of the brace.

Not sure what is meant my using a mill to cut tennons? I would use a circ saw to score cut the shoulders and knock the chunk out with a chisel, then par the tenon and shoulder.

Last edited by brad_bb; 04/02/08 04:52 PM.

|

|

|

Re: Hello, New Member here

[Re: DKR]

#14891

04/02/08 04:49 PM Re: Hello, New Member here

[Re: DKR]

#14891

04/02/08 04:49 PM

|

Joined: Dec 2006

Posts: 103

DKR

Member

|

Member

Joined: Dec 2006

Posts: 103 |

By the way, I think that generally a 2x6x4 tennon in an 8x8 is ok.

|

|

|

Re: Hello, New Member here

[Re: brad_bb]

#14893

04/02/08 10:44 PM Re: Hello, New Member here

[Re: brad_bb]

#14893

04/02/08 10:44 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

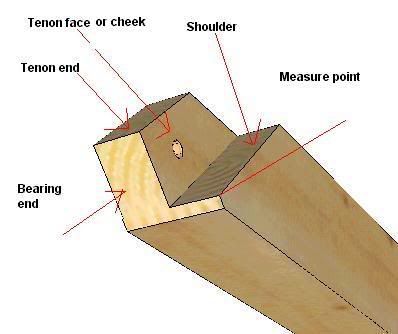

Yes Brad you hit it on the head with your description. As far as using the mill to cut tenons goes, I cut them while the cant is still laying on the mill and make the Cheek cuts.(I think thats what there called?) with the mill. Then make the other 2 cuts with a circle saw, Very fast in my world. Oh, and BTW, scorecut, par and shoulder,.... are all new to me, LOL you all, gonna have to work with me on the termanoligy, I have been a crane operator for the last 30 years LOL. I am really tired of being bottled up in that crane day in and day out. I figure, I have the mill, a log supply, most all of the support equipment (A Good sized forklift). And I kinda like to think I'm not so thick between the ears that I can't learn how to do this kind of work. I do Enjoy it. Ok I'll shut up.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14894

04/03/08 02:12 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14894

04/03/08 02:12 AM

|

Joined: Feb 2007

Posts: 56

CarlosCabanas

Member

|

Member

Joined: Feb 2007

Posts: 56 |

I would have put a tenon on the end of the post and the mortise in the "top plate". The way you are doing it the joint is in tension and relying on the pegs.

just my 2 cents

I cut it twice, and it's still too short!!

|

|

|

Re: Hello, New Member here

[Re: CarlosCabanas]

#14896

04/03/08 09:06 AM Re: Hello, New Member here

[Re: CarlosCabanas]

#14896

04/03/08 09:06 AM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Wouldn't that make all the weight of the sign & cantaleverd Beam be hanging from the peg at the top of the post?

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14899

04/03/08 10:35 AM Re: Hello, New Member here

[Re: The WoodButcher]

#14899

04/03/08 10:35 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

With a long sawmilled through tenon you may not even need the brace, but put one in for looks. Here is another term "reference face", When sawing the tenon put the ref. face down than make the cuts. Saw the shoulders first with the hand/skill saw. Then you won't have to back the blade out and risk pulling it off the wheels. In short the ref. face is the side you bace your lay out off. Tim

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14901

04/03/08 12:47 PM Re: Hello, New Member here

[Re: TIMBEAL]

#14901

04/03/08 12:47 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Woodbutcher: Here is a drawing showing some terms or labels:

Whatever you do, have fun doing it!

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14905

04/03/08 02:34 PM Re: Hello, New Member here

[Re: Jim Rogers]

#14905

04/03/08 02:34 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

I've never used a mill so I just pictured it like using a sledgehammer for a fly swatter. Maybe not, perhaps it's more like the bandsaw method in the "Braces" post.

Carlos, it's only hanging out there probably 4 feet or so, I don't think the pegs or tenon are in any danger of failure. The brace will be supporting most of the verticle. Also using the mortice and tenon would allow him to continue the post up for a finial or other embellishment. Plus I think it would look better.That's the way I would do a mailbox post too(and will in the future now that I know how to make a proper post with TF methods).

You are right in that it would be like a tie beam if you were actually building a hammer beam bent. So my analogy was a little misleading.

Brad

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14909

04/03/08 09:30 PM Re: Hello, New Member here

[Re: Jim Rogers]

#14909

04/03/08 09:30 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Wow, You all sound sharp! I'm impresed. Thanks Jim Rogers for the help with pix, I love it, keep it coming. I'm gonna be here alot I can tell. Here's a question for you all. I am going to turn my own pegs on the lathe, what should I use, oak?

Hey there TIMBEAL your are very right about pulling the band off the mill, that makes a nasty sound don't it.

Hey brad_bb , I can just lay the timber on the mill at an angle with the far end sticking off the mill & clamp in place. Works like a charm.

Last edited by The WoodButcher; 04/03/08 09:39 PM.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14911

04/03/08 10:37 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14911

04/03/08 10:37 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Use a shaving horse and a draw knife and make your own, faster than a lath.....  Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14912

04/03/08 10:50 PM Re: Hello, New Member here

[Re: Jim Rogers]

#14912

04/03/08 10:50 PM

|

Joined: Jan 2007

Posts: 12

The WoodButcher

OP

OP

Member

|

OP

Member

Joined: Jan 2007

Posts: 12 |

Need more input Jim Rogers what is that

|

|

|

Re: Hello, New Member here

[Re: brad_bb]

#14913

04/03/08 11:04 PM Re: Hello, New Member here

[Re: brad_bb]

#14913

04/03/08 11:04 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

tenons are usually 2inches with no pegging, 3-4in for a 1" peg with no tension, and 5 or more inches for pegs in tension.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14922

04/04/08 01:41 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14922

04/04/08 01:41 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

Oak is the most common material for pegs as it tends to have the highest shear strength against the grain. You can also buy pegs. I haven't bought any yet, but I found www.Pegs.us on the web. It looks like they are really set up to make pegs. I guess the question is, do you want to start making your frame, or make pegs for awhile.

|

|

|

Re: Hello, New Member here

[Re: The WoodButcher]

#14923

04/04/08 04:11 PM Re: Hello, New Member here

[Re: The WoodButcher]

#14923

04/04/08 04:11 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Need more input Jim Rogers what is that  It is a shaving horse with a peg in the clamp. I sent you an email about it. Jim Rogers PS: a quote from that email: this is what you need to make in order to produce your own pegs. We do this all the time. In fact one of the girls at the high school where I teach timber framing, at the after school program, are now making pegs at under 5 minutes each peg.....

Last edited by Jim Rogers; 04/04/08 04:49 PM.

Whatever you do, have fun doing it!

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14924

04/04/08 07:42 PM Re: Hello, New Member here

[Re: Jim Rogers]

#14924

04/04/08 07:42 PM

|

Joined: Aug 2006

Posts: 242

timber brained

Member

|

Member

Joined: Aug 2006

Posts: 242 |

Jim. Where do you find a shaving horse? or do you make your own? I prefer the riven pegs off the horse compared to lathed pegs, just the same as an axed timber over a sawn timber , as I think it allows the wood to have a say in its new shape. Welcome Woodbutcher, I believe black locust is also a great wood for pegs. tb

|

|

|

Re: Hello, New Member here

[Re: timber brained]

#14927

04/04/08 10:28 PM Re: Hello, New Member here

[Re: timber brained]

#14927

04/04/08 10:28 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Rain changed over to snow, so a short day. timber brained, a shaving horse is easy to make, an hour and you can be shaving pegs. I have a simple design via Bill Copperthwaite, it's based on simple living. The idea is any one can make this machine and move on to the item at hand, in this case pegs. This horse has no legs, you just set it anywhere, a chair, pony, chopping block etc.. It's light and easily moved, so it can be taken to the work site. It is friendly to young and old.

The problem is a picture is worth a thousand words and as everyone knows I don't do pictures. So I am going to try something else. We'll see if it works. Tim

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14929

04/04/08 11:35 PM Re: Hello, New Member here

[Re: TIMBEAL]

#14929

04/04/08 11:35 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Due to copy right laws I can't post any pictures of the plans of my shaving horse, because I got them out of a book. But I can email them to you. There are several ways to make them but the one I have you sit on and push on the pedal to clamp the peg stock between the clamp jaw called the dumb head and the ramp. It is very easy to clamp and un-clamp and we bore a test hole through the seat to test each peg through. You just keep shaving until it fits through. We start with straight grained red oak lumber and cut it on a table saw into squares just a little larger, say 1/8" then the finish size of the peg. At a shaker village, I visited a few years ago, I saw all different type, and sizes of shaving horses: Here are some:   And here is a close up of my horse with a peg in it's clamp:  Email me if you want the plans, anyone..... Wow, what a corrupt upload.....

Whatever you do, have fun doing it!

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14936

04/05/08 11:36 AM Re: Hello, New Member here

[Re: Jim Rogers]

#14936

04/05/08 11:36 AM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

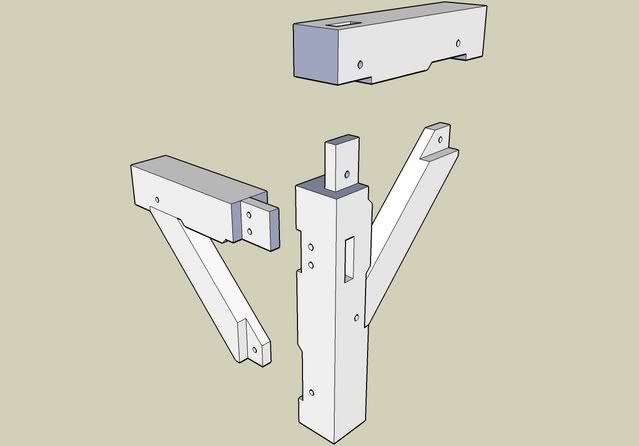

From Timbeal:  And:  He can explain these shots. Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: Hello, New Member here

[Re: Jim Rogers]

#14938

04/05/08 12:03 PM Re: Hello, New Member here

[Re: Jim Rogers]

#14938

04/05/08 12:03 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Thanks Jim, there is 2 knots with holes for testing peg fit, as Jim mentioned. No plans included it is up to the individual to make changes to fit their needs, just keep it simple. Shaving pegs is a kid friendly job. That is my daughters boot to the left. Time wise one of my sons, at age 13, made 60 pegs in an hour, after riving. I have found in sawn stock, the grain can run off, it's worth the time to rive. Tim

|

|

|

Re: Hello, New Member here

[Re: brad_bb]

#14942

04/05/08 07:40 PM Re: Hello, New Member here

[Re: brad_bb]

#14942

04/05/08 07:40 PM

|

Joined: Oct 2002

Posts: 209

Will B

Member

|

Member

Joined: Oct 2002

Posts: 209 |

Tenon length depends on the work it has to do, if any. 3" for minor girts, studs and braces, 4" for post tops, and longer than that for major horizontal members like tenoned joists, tie beams. If there's any tension at all, 5" would be a minimum. You have to balance that with the hassle of a deep mortise (if not thru). The weather problem with an exposed tenon end is a good point by Carlos. I would suggest making the tenon on the horizontal piece 5" long and using two 3/4" pegs 1.5" off the shoulder with 1.5" edge distance (3" in between pegs). Keeping the pegs nearer the shoulder gives good relish at 3.5"

Eric Sloane and "Woodworking in Colonial America" have plans for shaving horses.

|

|

|

Re: Hello, New Member here

[Re: Will B]

#14975

04/07/08 04:28 PM Re: Hello, New Member here

[Re: Will B]

#14975

04/07/08 04:28 PM

|

Joined: Jan 2007

Posts: 603

brad_bb

Member

|

Member

Joined: Jan 2007

Posts: 603 |

How do you get kids to sit and rive 60 pegs in an hour? I wouldn't think kids would have the pateince. Isn't it like punishment to them? Or do you place a Playstation in front of the horse? Is this a violation of child labor laws?

|

|

|

Re: Hello, New Member here

[Re: TIMBEAL]

#14991

04/08/08 01:49 AM Re: Hello, New Member here

[Re: TIMBEAL]

#14991

04/08/08 01:49 AM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

one of my sons, at age 13, made 60 pegs in an hour, after riving. 60 pegs! -- that's awesome. Oak? Green?

|

|

|

Re: Hello, New Member here

[Re: Gabel]

#14999

04/08/08 10:58 AM Re: Hello, New Member here

[Re: Gabel]

#14999

04/08/08 10:58 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

NO violation, family member. And a shaving horse is so far ahead of a play station, its not funny. There was one day he worked in the kitchen, shaving pegs for so long he had blisters. He has a self motivated drive. For the 60, I showed him the post and he said "no way it was 100" I said " come on, it was only 60" he said "probably". He was taking acccoustic up right base lessons and he rented the base, to pay for the rent he made pegs, a buck a peg. He would try and keep up with me when he was younger and now I have to keep up with him. I am not bragging with times, just sharing what is possible. I think, most folks think hand tool are slower, which they are, but they are also very efficient, and often more effective. As is the case with pegs. My experience with sawn and turned is grain run off. Tim

|

|

|

Re: Hello, New Member here

[Re: Gabel]

#15000

04/08/08 10:58 AM Re: Hello, New Member here

[Re: Gabel]

#15000

04/08/08 10:58 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

NO violation, family member. And a shaving horse is so far ahead of a play station, its not funny. There was one day he worked in the kitchen, shaving pegs for so long he had blisters. He has a self motivated drive. For the 60, I showed him the post and he said "no way it was 100" I said " come on, it was only 60" he said "probably". He was taking acccoustic up right base lessons and he rented the base, to pay for the rent he made pegs, a buck a peg. He would try and keep up with me when he was younger and now I have to keep up with him. I am not bragging with times, just sharing what is possible. I think, most folks think hand tool are slower, which they are, but they are also very efficient, and often more effective. As is the case with pegs. My experience with sawn and turned is grain run off. Tim

|

|

|

|

|