|

Re: historic hewing questionnaire

[Re: northern hewer]

#14824

03/29/08 07:01 PM Re: historic hewing questionnaire

[Re: northern hewer]

#14824

03/29/08 07:01 PM

|

Joined: Oct 1999

Posts: 463

Roger Nair

Member

|

Member

Joined: Oct 1999

Posts: 463 |

Hewer you wrote: The only thing that I could add to your fine explanation is that your comment of the slope being 9\11.

If you were using the square to layout the cuts bottom and top of the rafter you would use 9.81 (plus a little bit more) inches in 12 to arrive at the 108 inches rise in 11 feet of run.

I hope the quote comes out well. Anyhow, I think the simplest or least derived slope ratio is the way to go when at work. In this case, 9 ft. rise over 11 ft run. Hold 9 in. over 11 in. on the framing square and step twelve times for rafter cut length. Take a minute and examine the outside back face scales of the traditional framing square, inches divided by twelths. In a time when roof pitch or total gain was specified the simplest modeling and calculation can be accomplished on the square directly. Lets say a building is 28-4 wide with the roof rise of 11-5. Using the back face of the square hold 14 2/12 and 11 5/12 and step twelve times for rafter layout. For layout with the best accuracy use the square for setting trammels or large dividers. Precise length or slope in base 12 is not necessary. On the cost I bid $1,235 with no factual underpinning. Old builders manuals such as Trautwine and Audels have costs at their time of publication, it would be interesting to find a close contemperary to 1875.

|

|

|

Re: historic hewing questionnaire

[Re: TIMBEAL]

#14828

03/29/08 11:48 PM Re: historic hewing questionnaire

[Re: TIMBEAL]

#14828

03/29/08 11:48 PM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

Hi Timbeal

Yes the dovetails had pulled apart some, I suspected from the shrinkage of the wooden dovetails, and probably the shrinkage of the wooden chord timber. I noticed that the shoulder of the vertical posts had lifted up out of their mortises approx. 1\2", nothing really to get excited about, but there was movement.

Well as promised here is the agreed cost between the school trustees and Elias Snyder the builder.

as stated "I bind myself to build said school house according to plan, and specifications, for the sum of $450 dollars to be paid in May and the rest when the building is completed".

At the bottom of the document there was a final entry--

"received sum of $485 of the trustees lot #6 Being the full amount in full dues 1877 Dec 26"

Elias Snyder

PS I notice that he also needed a few extra months like the contractors of today usually do

NH

|

|

|

Re: historic hewing questionnaire

[Re: northern hewer]

#14829

03/30/08 12:13 AM Re: historic hewing questionnaire

[Re: northern hewer]

#14829

03/30/08 12:13 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

Hi Roger

Well your reply to the rafter cutting is very interesting and I take my hat off to you!!, and may those looking in take heed of your comments.

The square is sure an interesting tool, and if well mastered one can do just about anything with it. I have in my possession an old text book that deals only with the "Steel square", may times I have read it.

Thanks for quoting on the cost of the school building, I am at a loss to know what the comparison between US and Canadian currency was at that time. I do know that British pounds were still floating around right up until confederation in 1867.

My dad who was a pretty good carpenter said that during his career he met one fellow that amazed him in his ability to produce any number of complicated cuts with his square, hardly ever making an error. My dad used to set me down as a young man and explain to me as much as he could what he knew about using properly the inscriptions on both sides of a good framing square. After he passed away some time ago I inherited his tools and I cherish especially his square, which by the way I never was allowed to use

Once in a while he would clean it thoroughly, and rub white paint into the markings to freshen it up and make its use easier.

Anyway thanks for the reply and information, I believe that every one aspiring to do carpentry, or timberframing should have a course in the use of the framing square, real early in their career.

NH

|

|

|

Re: historic hewing questionnaire

[Re: northern hewer]

#14843

03/31/08 11:22 AM Re: historic hewing questionnaire

[Re: northern hewer]

#14843

03/31/08 11:22 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Roger, thanks as well. I have a rafter book comming from Summer Beam Books and hope it shines more light. I have always used a 12 base for rafter layout. The 10th and 12th on the square have been a sore spot, I use the cheeper squares with 1/8's for general layout. I hope to find a better use for the traditional square. In some drawings of historical structures you will see a pitch in a base 12 with a rise of some odd fractioned number say 6-3/4", and I think you just explained it. Thanks

It seems I am more of a traditionalist than I thought. The builder of the school went over the time limit by a few months. That is where it comes from, it's a tradition. And I was a bit high on the quote. I have some prices of my Grandfathers boat work, where the numbers are very small in comparision to today. They almost worked for pennies a day. But the workmanship was much more. Tim

|

|

|

Re: historic hewing questionnaire

[Re: TIMBEAL]

#14852

03/31/08 09:47 PM Re: historic hewing questionnaire

[Re: TIMBEAL]

#14852

03/31/08 09:47 PM

|

Joined: Oct 1999

Posts: 463

Roger Nair

Member

|

Member

Joined: Oct 1999

Posts: 463 |

Thanks guys, but I'm just passing along things that I have learned from others. So I salute all the fine carpenters I worked under as a young man.

|

|

|

Re: historic hewing questionnaire

[Re: Roger Nair]

#14857

03/31/08 11:39 PM Re: historic hewing questionnaire

[Re: Roger Nair]

#14857

03/31/08 11:39 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

wow, what a thread this has turned out to be. thanks for a good one, NH!

|

|

|

Re: historic hewing questionnaire

[Re: ]

#14951

04/06/08 12:59 AM Re: historic hewing questionnaire

[Re: ]

#14951

04/06/08 12:59 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

Hi Derek:

I said don't worry about the spelling and thanks for the words, my old grandfather Michael couldn't spell his name but he could sure hew timber, and by the way he liked to get the young fellows together and see who could out lift him. Not many could.

He held the record at that time for the number of logs chopped down and square butted in one day.

I will be back with some more good pics I am readying for posting in a few days.

NH

|

|

|

Re: historic hewing questionnaire

[Re: northern hewer]

#14962

04/07/08 12:56 AM Re: historic hewing questionnaire

[Re: northern hewer]

#14962

04/07/08 12:56 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

Hi Everyone For those interested in half dovetail timberwork, here is a good historical example of a halfdovetail used in heavy timberwork associated with the timberframework in the 1847 Muley Sawmill at UCV. You will notice the 20" square 30 foot white ash timber being suspended in a shared dovetail mortise cut into sister posts, the dovetail is securely held in position by wedges driven in from the outside. Just for your information there is an identical timber right below the floor that is also suspended in the same fashion. this mill was constructed by the Beach Brothers who were English millwrights that was sent to this area by the British Government to establish mills in strategic locations to encourage settlement. I hope you enjoy NH

|

|

|

Re: historic hewing questionnaire

[Re: northern hewer]

#14963

04/07/08 12:59 AM Re: historic hewing questionnaire

[Re: northern hewer]

#14963

04/07/08 12:59 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

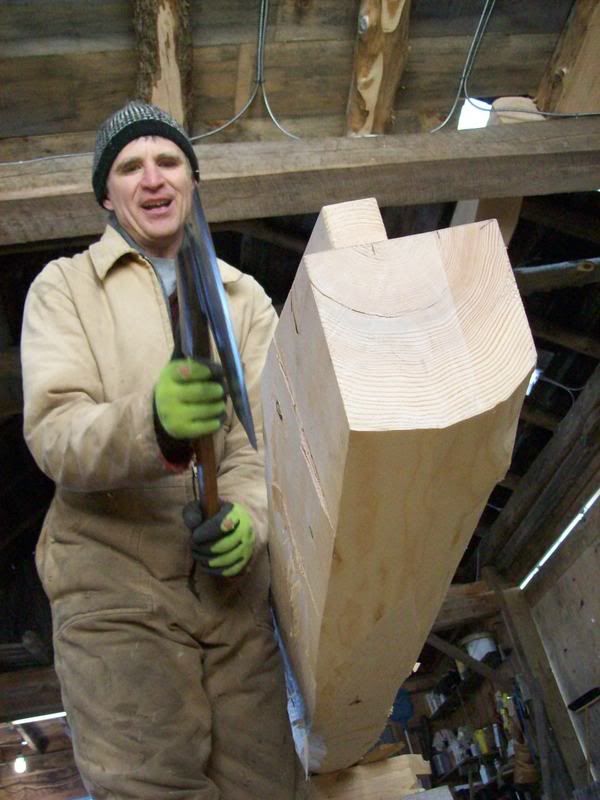

Hi Roger:

It looks like you swing a pretty mean broadaxe good photo.

Nh

|

|

|

Re: historic hewing questionnaire

[Re: northern hewer]

#15079

04/12/08 01:13 AM Re: historic hewing questionnaire

[Re: northern hewer]

#15079

04/12/08 01:13 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

OP

OP

Member

|

OP

Member

Joined: Mar 2002

Posts: 1,198 |

Hello everyone: Here is a sideview of the same timber to just give you alittle better prespective of the the extremely heavy timberwork associated with the mill framing just above the vertical blade and its guides and many parts. Notice also the very long sway braces that were used throughout the framework both on this level and on the lower level. This long bracing was necessary to hold the mill as steady as possible while the machinery was in operation, due to the jerky forward motion of the sawframe that advanced with each stroke of the vertical saw . NH

Last edited by northern hewer; 04/12/08 01:20 AM.

|

|

|

|

|