|

Pegs -- riven, sawn, drawn, turned, driven, etc?

#16056

06/27/08 07:21 PM Pegs -- riven, sawn, drawn, turned, driven, etc?

#16056

06/27/08 07:21 PM

|

Joined: Nov 2003

Posts: 687

Gabel

OP

OP

Member

|

OP

Member

Joined: Nov 2003

Posts: 687 |

What do you guys see? I have only seen drawn or otherwise shaved pegs in frames around here. And they're always made of dense, virgin, heart pine (southern pine) never a hardwood. Most pegs seem to be hastily made -- "good enough" seems to be the rule of thumb on the shaping. Some are roundish, some are octagonalish, some are very tapered along their whole length, some are pretty well straight w/out much taper, some I have seen evidence in these 40' kingpost trusses from the 1840's that at least some of the pegs were made from the waste blocks from the timbers -- there were some crudely shaved pegs with the end left square. On several of them, one face was water sawn and 3 were riven and on one peg, 2 adjacent sides were riven and the other 2 adjacent sides were water-sawn, which indicates it came from the corner of a sawn timber or plank. All of the wood in the trusses except the 42' long bottom chords was water sawn. I have seen photos of old frames w/ turned pegs and I have heard of pegs shaped by driving them through a hole in an iron/steel plate. Have any of you guys seen these kinds of pegs? If so, in what building? What different kinds of pegs have you guys seen in old work? are they tapered or straight? what is the point like? are they octagonal or rounded?

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16065

06/28/08 01:43 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16065

06/28/08 01:43 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Gable, I see mostly rived spruce pegs, 1", 8 sides, with a 4 sided point about 1-1/2" long and not much taper, fairly crude I don't mind saying. Once and a while I will see some hard wood pegs Oak or Maple.

I love my hand made pegs, they taper far more than the one I see of old.

I have tried sawing peg stock and shaving the taper and extra 4 sides with a draw knife, it was ugly. Riving is the way to go.

I need to take a closer look to see if the few buildings which are square ruled have tapered pegs, or at least more taper than the scribe ruled buildings, which form the bulk of the buildings In my area. Tim

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: TIMBEAL]

#16071

06/29/08 07:47 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: TIMBEAL]

#16071

06/29/08 07:47 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Gabel,

Metal plate dies are really used to check the final size of a rived peg to make sure that it does not overfill the peg hole causing split out the cheek or tenon thus a normal tapered octagonal peg would be made and then tapped through the hole. Should any excess wood be removed then this would leave a cylindrical surface on the leading "edges" of the peg. The aim is not to completely fill the peg hole but instead allow slight edge deformation on the peg facet edges

Peter McCurdy (builder of the Globe Theatre) brings along a bag of pegs when he teaches sessions on the Timber Building Masters course at The Weald & Downland and this bag contains all sorts of rareties and oddities that tend to alter long held perceptions on the right or wrong way to peg a joint.

Some simple considerations might be as follows :-

Durability:- where a peg is exposed externally then the ability of the peg to survive weather and bug attack is important so oak and chestnut would be a good choice and ash a poor choice.

Flexibility:- pegs will deform in service and in fact need to be able to do so otherwise the tenon relish might split or pull out, worse would be when the peg is located too close to the edge of the arris causeing the cheek to split out. The likelihood of this type of failure mode being encountered is made worse by using rows of close spaced pegs e.g. as in arch braces where large shrinkage is expected. Ideally pegs should behave like springs rather than fixed restraints allowing a degree of movement but basically holding everything together. Soulace brace joints present a particular challenge for pegs.

Failure:- Pegs should fail preferentially before tenons or cheeks. Its much easier to replace a peg than repair a joint. Peg grain should be set with the annular rings parallel to the direction of developed force such that all rings are made to work together. There are differences between the crushing strength of early and late late growth wood and also differences year to year. The objective is thus to reduce the effect that weaknesses in annual growth rings might have in allowing preferential crushing or worse still ring separation potentially resulting in the loosening of a joint.

Grain:- not sloping and ideally wood species that exhibit long fibres with peg material taken from any clear wood avoiding juvenille and sap wood with clear growth areas being found between annual growth knot whorls or branches. Pine can be used along with oak, chestnut, cherry. Avoid brittle woods such as yew and elm and some (black) ashes where separation or "shelling out" can be encountered. Don't use soft pulpy woods such as aspen, willow, poplar which will yield in service.

Profile:- tapered pegs are used to draw a joint up tight that employs offset boring. Parallel pegs are used on drilled through assemblies where joints are pre tensioned by pulling up with come-a-longs or equivalent Spanish windlas. Parallel pegs are also used on centre line set tenons where a tapered peg might fail to pull the joint up tight before locking on its outside (thick) end. Square pegs are used to lock lap joints or joints where separation of both parts is to be resisted e.g. cruck blades, rafter peaks, common rafter to purlin.

I hope that this helps.

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Ken Hume]

#16072

06/29/08 01:02 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Ken Hume]

#16072

06/29/08 01:02 PM

|

Joined: Nov 2003

Posts: 687

Gabel

OP

OP

Member

|

OP

Member

Joined: Nov 2003

Posts: 687 |

Thanks for the info Ken --that is a thorough intro to pegging that many will find quite helpful. Perhaps when we can add topics to TFwiki that could serve as a start on a peg entry?

You mentioned Mr. McCurdy's bag of odd pegs -- I infer that there is quite a wide variety in types and shapes? Is there one type that is seen more than others? Is there any consistency across regions or time frames or does it seem to be locally and date specific? (or random?)

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16073

06/29/08 01:48 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16073

06/29/08 01:48 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

pegs here in ontario are all riven, then drawknifed hardwood, mostly oak. I see the old builders doing the same thing I do, in that there are different tapered pegs in some holes. I assume this means that the builder knew which holes where over drawbored, etc.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Mark Davidson]

#16096

07/02/08 01:22 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Mark Davidson]

#16096

07/02/08 01:22 AM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Hi Gable;

I agree with everything Ken wrote. In my experience in Northern New England I have never seen evidence of a peg shaped by driving it through a metal plate. I had formed my own opinion that draw-bored joints have long, slender gently tapered pegs. Sometimes they very in diameter which makes me think they may have been adjusted in size if the draw-boring holes were too far out of alignment. Red oak seems to be predominant but I have seen red maple, pitch pine (the only southern yellow pine which grows in Maine), and spruce. Powder post beetles seem to like red oak better than softwoods and the oak pegs show more damage than the framing. Most holes I have measured are 7/8". The smallest holes I have seen were 5/8" in a lightly framed 14'x40' carrage house.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16097

07/02/08 01:46 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16097

07/02/08 01:46 AM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Two more things, I have only seen one barn in New England with un-pegged braces although I understand having un-pegged braces is the rule in parts of the Mid-West and Central Canada. I have only seen one barn (circa 1857) in New Hampshire, with turned pegs.

Does anyone have a preference to call pegs pins or vice versa?

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16100

07/02/08 09:09 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16100

07/02/08 09:09 PM

|

Joined: Aug 2007

Posts: 21

Sussexoak

Member

|

Member

Joined: Aug 2007

Posts: 21 |

Yes,

Pegs are for hanging your hat on.

Pins are tapered pointed articles to secure things together with.

So it should really be pins, but pegs, possibly derived from architects specifications for repairwork, has held sway for many years now.

Walter Rose, in the Village Carpenter, writes about Pins, from his recollections of carpentry in the 1880s.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16101

07/02/08 09:21 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16101

07/02/08 09:21 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

What about "tree nail" or trunnel... I could be wrong, but I doubt there is anyone alive using these terms. What say you Northern Hewer!?1?

I like "peg."

"Pin" sounds/ conjures up images of the metalic for me. But that's just me and likely reflects my woodworking history.

I did not pay paricular attention to pegging during my recent barn surveys. But I do remember most pegs had a rustic-looking nature... I don't believe I saw anything nice and smooth like turned pegs. And I think everything was tapered and protruded a good distance from the timber.

I don't recall seeing unpegged braces, but have heard of the practice.

And regarding "steel plates"... I know I've read this and seen diagrams in books. The thick plate had a concave/chamfered set of holes. The peg was rived to approx. diameter and then pounded through... I don't know how historically accurate this really is. Wouldn't it make a poor and weakened peg from all the pounding?? Straight grained wood should have been quite easy to rive to an approximate diameter. A block plane could have been employed if you really needed to get it perfect.

As far as draw-boring, I assume the only way to tell if a joint was draw-bored would be to dissasemble it. But would tapered pegs be used on a non draw-bored joint? I would think a slight chamfer would do fine on a non draw-bored joint, but I don't ever recall seeing chamfered pegs, only long tapers. Does that mean they're all draw-bored joints?

"Tree nail" is an interesting word/phrase. I have often wondered if siding/boarding was ever attached w/ pegs. Nails were costly luxurys back in the day. Has anyone ever heard of boards being attached w/ pegs? If you bored holes at slight downward( or even opposing) angles, I'd think you could attach wall/ roof boards this way.

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16105

07/04/08 01:07 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16105

07/04/08 01:07 PM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Sussexoak; do you make any distinction between pins being used for attaching planks to framing verses holding a mortise and tenon together? I originally learned to say pegs but I have seen your distinction between pins and pegs before. Often in dictionaries, etc. the words pins and pegs are used interchangeably and dowel is sometimes used. It seems these defintiions are cloudy enough that if someone intends a specific meaning they should spell out there intent. I will try to say "pins".

Not to further confuse the use of the word pin, I have come across a discription of a housed dovetail joint being referred to as a pin-and-socket type of joint, in generic terms.

Don, I do not recall seeing boards pinned to framing but it was common to pin floor planks to joists and vertical wall planks to sills/girts/plates. One type of rafter foot is cut flat without a tenon and a 2" trunnel installed through the rafter foot into the tie beam.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16107

07/04/08 01:28 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16107

07/04/08 01:28 PM

|

Joined: Apr 2002

Posts: 895

daiku

Member

|

Member

Joined: Apr 2002

Posts: 895 |

Just to add to the confusion: in cabinetry, the two parts of a dovetail joint are called "pins" and "tails". In our shop, we say "pegs". CB.

--

Clark Bremer

Minneapolis

Proud Member of the TFG

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16108

07/04/08 09:18 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16108

07/04/08 09:18 PM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi,

Its odd - but when a timber frame is being trial asembled it is common practice to use tapered steel pins to pull the assembly together but later when being erected in its final place - wooden pegs are employed. Same hole but different terminology (pins / pegs) depending on whether or not the securing device is removeable ?

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: TIMBEAL]

#16113

07/06/08 12:06 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: TIMBEAL]

#16113

07/06/08 12:06 PM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

This is typical to what I see –  Oaken, octagonal and most often, well drawn, with a short taper and a four sided point. Almost without exception these are 1” Like Jim, I have seen few examples of turned pegs in homes and barns, in my case I have come across two exceptions, both atypical in various other aspects also. (one had a trussed and suspended floor, the other the only example of centered braces in an SR frame I’ve come across) Both were built by wealthy industrialists, bringing weal (read that: conspicuous consumption) back to their hometowns. Trunnel – is still in common usage in the Bridgewrighting community, and (like the wiki suggests) is used in referring to the large pins that are common to bridges. As an aside to that, (and in contrast to the norm) turned pegs, even in small diameters are common to bridges, even early examples. This likely due to the constant forces found in them, and the desire for full bearing on the pins, and the logic of adding a bunch of 1” to the 1 ¾ “ order. These orders perhaps filled on typical lathes early on, but eventually this led to the advent of specialty trunnel lathes – As this trunnel spam suggests – click on the photo. http://tfguild.org/forums/ubbthreads.php?ubb=showthreaded&Number=9618&page=

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Will Truax]

#16118

07/06/08 05:46 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Will Truax]

#16118

07/06/08 05:46 PM

|

Joined: Nov 2003

Posts: 687

Gabel

OP

OP

Member

|

OP

Member

Joined: Nov 2003

Posts: 687 |

that's a cool video -- really neat to see it in action.

So these turned trunnels are for transfering shear when you need to have no slop in the connection? Makes sense. I'll have to go to the local bridges and see what sort of pins/pegs/trunnels they have. All the local surviving bridges are lattice, so plenty of trunnels in them.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Gabel]

#16119

07/06/08 07:19 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Gabel]

#16119

07/06/08 07:19 PM

|

Joined: Feb 2006

Posts: 718

Dave Shepard

Member

|

Member

Joined: Feb 2006

Posts: 718 |

I have only seen turned pegs in the few lattice bridges I have seen. I think I read somewhere that is the norm, could be wrong. I call'em pegs, usually.  Dave

Member, Timber Framers Guild

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16121

07/06/08 09:08 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16121

07/06/08 09:08 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Don, I do not recall seeing boards pinned to framing but it was common to pin floor planks to joists and vertical wall planks to sills/girts/plates. One type of rafter foot is cut flat without a tenon and a 2" trunnel installed through the rafter foot into the tie beam.

Jim

Hey Jim... So have you seen boards pinned/pegged to framing? Sills and girts and plates are framing members. Has anyone else seen heard of this? What kind of building was it Jim, and how old...where? I too have seen the 2" trunnel on the end of a rafter. One of the barns had a rough winter here and the snow snapped one of the major rafters. The carpenter putting it back to gether remarked about the "huge dowel" pinning the rafter to the crosstie. Tim: Those definitions are interesting. I wouldn't have thought there were so many forms of each word. I don't really have a preference what we call pins/pegs... but like I said before, "pin" sounds metalic: hinge pin cotter pin split pin wrist pin hat pin saftey pin pin the tail on the donkey! Will, that photo is typical of what I see here in Maine as well. And neat video.

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16122

07/06/08 09:16 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16122

07/06/08 09:16 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Funny, but "pin" feels more natural to use as a verb rather than a noun:

"pin that joint together"

"how did they pin the rafters at the peak?"

But I wouldn't say, "It will be hard to find a barn with pins made on a lathe..."

So maybe it's how we are using the word pin/peg?

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16124

07/07/08 01:26 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Gabel]

#16124

07/07/08 01:26 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Gabel – I believe most of Georgia’s surviving bridges are attributed to W.W. King, son of your best known bridgewright, Horace King – They built Town’s Lattice trusses almost exclusively, so you will find trunnels aplenty, but… Large diameter trunnels are not exclusive to Towns If you haven’t seen this film yet, you’re gonna want to - http://www.youtube.com/watch?v=4qQWPX3oaNU Jim & Don – The trunneled rafter to tie connection is a hyper regional variation unique to coastal Maine & NH – I know of but one inland example, got pix, I’ll upload to p-bucket and post one tomorrow

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Will Truax]

#16125

07/07/08 11:14 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Will Truax]

#16125

07/07/08 11:14 AM

|

Joined: Nov 2003

Posts: 687

Gabel

OP

OP

Member

|

OP

Member

Joined: Nov 2003

Posts: 687 |

Will

I'm a little familiar with the King's work -- but I have never seen that video. Thanks for passing that along, it looks like it will be great!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16131

07/07/08 08:02 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Housewright]

#16131

07/07/08 08:02 PM

|

Joined: Aug 2007

Posts: 21

Sussexoak

Member

|

Member

Joined: Aug 2007

Posts: 21 |

The pins I am referring to are for securing a mortice and tenon joint.

As Ken points out, the mortice and tenon is temporarily secured during layout with a hook pin, a metal tapered pin.

But remember also that the tapered framing pins are able to be removed by drifting them out from the inside of the frame.

I use "treenail" for the square pegs fitted into a round hole, used to secure scarf joints together and to secure purlins to rafters etc.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Will Truax]

#16132

07/07/08 09:28 PM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: Will Truax]

#16132

07/07/08 09:28 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Jim & Don – The trunneled rafter to tie connection is a hyper regional variation unique to coastal Maine & NH – I know of but one inland example, got pix, I’ll upload to p-bucket and post one tomorrow

Will, I do not have a picture, but I saw it w/ my own eyes. The carpenter can attest as well. The barn is in New Gloucester, Maine, about 7 miles from where we'll be meeting this weekend... all hand hewn from the early 1800's... and it's a CG. Interesting that it's regional like you say. This particular barn is about 15 miles inland (according to Google maps). Don

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16133

07/08/08 10:19 AM Re: Pegs -- riven, sawn, drawn, turned, driven, etc?

[Re: OurBarns1]

#16133

07/08/08 10:19 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Don’t know the extent of the range, just know what was shared at TTRAG ’04 and that I don’t see it in my neck, which is not all that far inland. I did find it in this Meeting House carriage shed, a little to the south west and farther inland, and an area whose buildings I am very familiar with…  A level cut and a trunnel – So I guess we’re still on topic.  Don’t think the hinges are, but I couldn’t resist.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Will Truax]

#16137

07/08/08 05:07 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Will Truax]

#16137

07/08/08 05:07 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

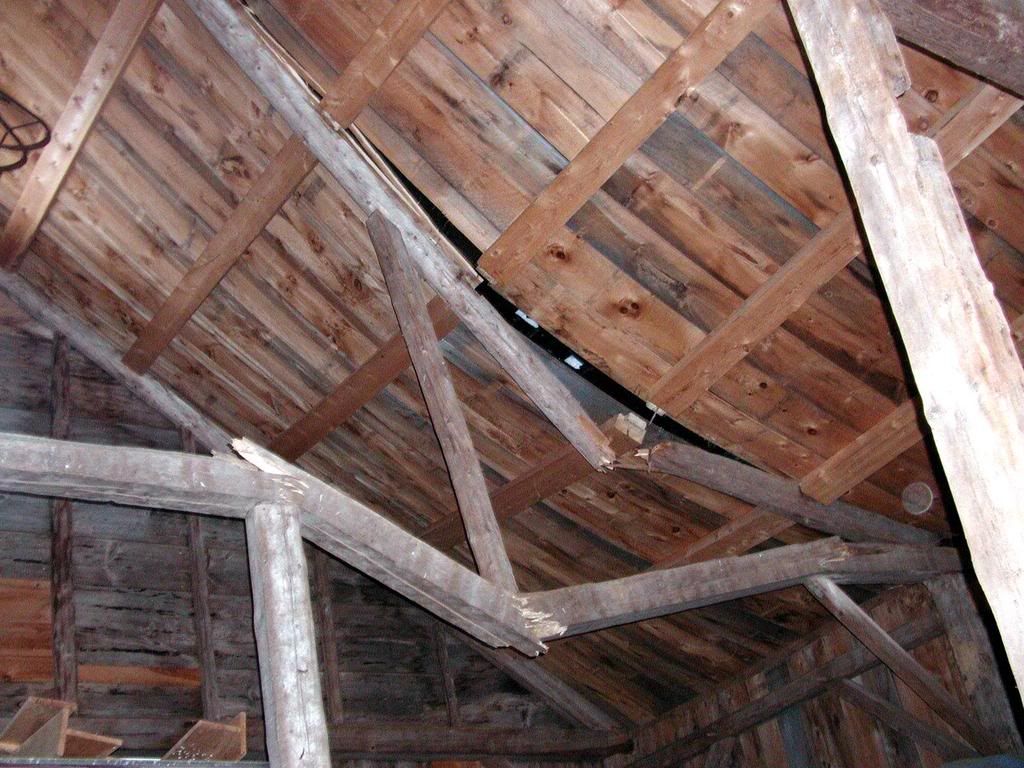

Will: Interesting that the trunnel protrudes through the crosstie. I'm not 100 percent sure, but in the barn I saw, no evidence can be seen... you have to remove roof boards to see the top of the trunnel: the bottom cannot be seen. The only way we saw it was upon the carnage. Check the photo. The snow got the better of this one.  The barn was built w/ undersized timbers 6x6. And the purlins-- that are spiked to the rafter--and roof deck are replacements from a restoration about 10-15 years ago.

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16138

07/08/08 05:09 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16138

07/08/08 05:09 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: ]

#16147

07/09/08 11:50 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: ]

#16147

07/09/08 11:50 PM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Don;

I wrote that I do not recall seeing boards pinned to framing, only planks. I that what you are asking me about?

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16149

07/10/08 01:20 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16149

07/10/08 01:20 AM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Jim

I guess I was wondering about pin/peg use outside of timber-to-timber joinery. Sounds like you have seen planks pinned (to joists, right?) Were the pins/pegs like normal timber-to-timber ones or different? Were they inserted at an angle, etc?

My curiosity stems from the whole "treenail" concept. Because nails were rare/costly, I think treenails could have been used to fasten sheathing/boards.

I guess this begs the question on the origin of the word "nail." You know, a sort of which came first kind of thing: the peg or the nail? (I know it's the peg, but why refer to them as "nails" at all?)

Treenail is a sort of hybrid word that hints they (pegs/pins) were used as nails.Maybe a look in the old dictionaries about "nail" would be interesting. It's origin and date etc.

KEN,

Are you listening? Have you seen pegs/pins/treenails attaching boards or sheathing?

I'd like to try it sometime...

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16150

07/10/08 06:51 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16150

07/10/08 06:51 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Don,

I am struggling to think of examples but one that does come to mind is ship decking where nails would corode quite quickly in service.

Another might be in the construction of clay dabbins, a rude cruck variant found in the Solway Firth area on the border between Scotland and England. These have plank roofs where the planks interlock and are pegged at the ridge running vertically down to sit on top of the side purlin and / or wall plate and where lower "half" planks are fitted then this is done by driving a treenail through one end of the plank which is then simply hung over the purlin and draped over the wall plate at the lower end. No pegs are applied at the lower ends of the plank rafters. The whole roof is then covered with turfs. Check out "Clay Dabbins - Vernacular Buildings of the Solway Plain" by Nina Jennings (ISBN 1-873124-38-4). My son gave Will Beemer a copy of this book so anyone visiting Heartwood School can check this out in their library.

I will forward the question about nails to Chris How MSc. (timber building expert) in Australia who is currently preparing a thesis on nails with professor Miles Lewis at Melbourne University.

The problem with using treenails with thin members would most likely relate to splitting of the thin member especially when driven near the ends which makes the clay dabbins example all the more intersting.

Is "clay dabbins" in the glossary.

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Ken Hume]

#16151

07/10/08 10:21 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Ken Hume]

#16151

07/10/08 10:21 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I think it is in one of Sobons books where there is mention of pegs at the eve to support a gutter. The gutter just sat on the peg, not through it. They found evidence of peg holes along the top plate which suggested a gutter? The original gutter system of course was long gone. Tim

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16153

07/10/08 02:08 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16153

07/10/08 02:08 PM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Don,

I have received the following email reply from Chris How in Australia and an extract from the same follows :-

Try CF Innocent pp176/177 for slate pegs. You may find the Romans used pegs to affix slates of stone or tile. Why the term trenail is used I guess is that the “peg” then fulfills another function, which is actually to effect a joint, against the peg, which is only to hang the slate or tile. The first settlement at Sydney in Australia used pegs thro cleft shingles, but these expanded when wet and cracked the wooden shingles, so there was an appeal to the motherland for shingling nails.

Nails go back to at least 3000BC so there is little point in asking why the word originated. We take “nail” from the Germanic/Norse root NAEGEL, whereas the French take “clous” from the Latin root, CLEVUS. The modern German word for trenail is DUEBEL, pronounced Derbelle, or T’derbelle. With some stretch of the imagination one could suppose that there is a phonetic shift from the Anglo-Saxon which would corrupt towards “trenail” given 1200 years or so. The Germans do not have a distinction between a peg and a trenail, so far as I am aware.

I read recently somewhere that the decorative head on spikes derives from their origins in timber which were left projecting and chamfered off or sculped out for appearance sake. These show in some German illustrations, but I know of no English equivalent. It may also be in Innocent.

There is a heritage woolshed in South Australia which has a red gum floorboards onto joists of red gum, all pegged together. Very unusual, even for Australia. So far as I know these are vertical holes and not angled. The driving–in process gives the tight fit required. There must be Medieval equivalents in UK of same.

There is a theory that nails derived from thorns used as pegs in the middle east, but the earliest illustration I have seen was a bronze age cast bronze nail. Fiona Keith Lucas may know what the ancient Egyptians used.

Most ship-board terms are straight Anglo-Saxon and convert across to specialized forms in mining/civil engineering terms such as “head-tree”. Can’t think of anymore at present.

C How

Looking back to see the way ahead !

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16154

07/10/08 02:11 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16154

07/10/08 02:11 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Pegs that hold up wooden rain gutter were common in Dutch barns:

Whatever you do, have fun doing it!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Jim Rogers]

#16158

07/10/08 08:18 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Jim Rogers]

#16158

07/10/08 08:18 PM

|

Joined: Feb 2006

Posts: 718

Dave Shepard

Member

|

Member

Joined: Feb 2006

Posts: 718 |

I'm gutting the interior of a c.1830 timber frame. There is a peg sticking down through the wide floor plank from the second floor. It has been draw shaved, and is nowhere near any of the main timber components of the frame. Hopefully I will be able to get a better idea of what it is there for as we open up the frame.

Dave

Member, Timber Framers Guild

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Dave Shepard]

#16159

07/10/08 09:10 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Dave Shepard]

#16159

07/10/08 09:10 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Great comments Ken and others.

Chris How's nail study sounds wonderful. Funny how such a "common" (pun intended) item as a nail could busy someone in scholarly reasearch for months even years at a time.

The thorn hypothesis is esp. interesting (must have been nasty thorns!)... The clay buildings w/ pegged roof boards that you mention Ken sound neat. I'll ask my brother in law who's a Scot about them. And pegging ship decking makes perfect sense.

But given the above responses, it appears that pegs were not used to apply sheathing to structures as a common practice. I had guessed it would have occured here in early America, and esp. Europe.

Oh well-- I still think I'll give it a try sometime on a wall.

If you used oak or hickory "treenails" say 3/4" dia. and drove them in at opposing angles, I'd think you'd have a good method. Not as good as real "nails" but good enough for a barn or other outbuilding that would require some economy. etc.

But there must have been a reason why it wasn't done.

may the education continue...

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16161

07/10/08 10:29 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16161

07/10/08 10:29 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

In Jack Sobon's articles about his constructing his English side entry barn, he created a groove in the bottom side of the tie beams for the siding to stick up into. This eliminated the need for a nail up there, thus reducing the over all total count needed for siding a barn.

There are old stories about how after a fire, in colonial times, that they go to the cold ashes where the house stood and find all the nails that were used in the house.

And reuse them.

The nails that were used to make a plank a door were usually too long for the thickness of the planks. And the tips were bent over on one side. When these "fired" nails were found and they tried to straighten them out; these bent points would break off. And you'd have a very short blunt nail that was not very usable.

And this nail was considered, "dead." And that the origin of the old saying "Dead as a door nail.".......

Interesting for sure.....

Whatever you do, have fun doing it!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16162

07/11/08 02:11 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16162

07/11/08 02:11 AM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Hi Don;

I have seen barn floor plank trenailed to the joists several times. I believe one barn they were skewed (toed, angled). I cannot recall the spacifics about the estimated age or even the type of barns. The most receint example was a single reused joist in connecting girt barn, I could not tell what type of barn the reused piece came from. Typically they are oak, 1" square pegs installed through the 2" plank and 1" subfloor boards into the joists and hold quite well.

A circa 1720 saltbox cape plank-on-frame house from Conneticut I reassembled had 1.5" pins holding the 1.5" oak planks to the oak frame only in the planks beside each original window opening and only into the girts, not the plates, ties or sills. All other fastening was with wrought nails. The 1" oak roof sheathing boards were nailed on.

Some plank houses have pins installed in the plank edges, between each plank, they are joggled. These pins keep the planks in line with each other and help prevent racking since only first-period houses seem to have bracing; most plank houses have no bracing.

I looked tree nail up in a few dictionaries and it is mostly referred to attaching planks to the frame in wooden shipbuilding with black locust being the best material because of strength and low shrinkage. Trunnel is a corruption of tree nail.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16163

07/11/08 02:34 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16163

07/11/08 02:34 AM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Hi everyone; I had not read the last few posts before my previous reply so here is some more information.

To clarify, Jack Sobon did not create the idea of a groove to hold boards without using nails. It is an early traditional practice, at least here in New England. There are plank grooves too.

Fire door clinch nails are still available for purchse and work well. Clinching the ends of the nails makes them act like screws, they hold two boards together much better than a simple nail.

I had forgotten about using pins to hold roof tiles in place, there are examples of this at Old Salem, North Carolina.

Interesting thread.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16164

07/11/08 06:55 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Housewright]

#16164

07/11/08 06:55 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Jim R,

Chris How just sent me the following rendition :-

“There he was crepyde in-to a krage and crouschede to ye erthe;

Ded as a dore-nayle doun was he fallen.”

Parlement of the Thre Ages. Unknown. 14th Century.

Regards

Ken Hume (after C How)

Looking back to see the way ahead !

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Ken Hume]

#16166

07/11/08 02:04 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Ken Hume]

#16166

07/11/08 02:04 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Jim:

I didn't say he created the idea, he just wrote that he used it.

I know he didn't create it as it has been found in older frames before.

Jim

Whatever you do, have fun doing it!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Jim Rogers]

#16168

07/11/08 08:53 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Jim Rogers]

#16168

07/11/08 08:53 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

A groove is a great idea. So simple.

I wonder why only floor planks got pinned/pegged.

I've also heard of folks collecting nails after fires... and wasn't a sign of wealth a front door w/ many extra nails?

As a side note:

looking forward to seeing folks tomorrow for the CG tour!

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16169

07/11/08 09:02 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16169

07/11/08 09:02 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Gabel:

Now that we've chimed in, does what you see in the south differ to a great extent? Ever seen pegs employed in ways other than joint-to joint, etc?

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16170

07/12/08 12:55 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16170

07/12/08 12:55 AM

|

Joined: Nov 2003

Posts: 687

Gabel

OP

OP

Member

|

OP

Member

Joined: Nov 2003

Posts: 687 |

Don,

The main difference is that I've yet to see a hardwood peg in an old frame in Georgia -- they're all heart pine. sometimes 30 rings to the inch. Mostly 1" holes. Pegs are riven and shaved to a taper. Some octagons, some rounder than that. All draw bored. Some crude, some well made. Sometimes in the same frame.

Honestly, I am often guilty of not looking closely at the pegs in a frame -- something I think a lot of us do. That is one of the main reasons I started this thread. If nothing else, a few of us will be paying more attention to the lowly peg next time we visit an old frame.

I can't think of any cases of things other than joints being pegged that I've personally seen. Oh, here's one. The window and door bucks on hewn log buildings were usually pegged with fairly large pegs -- 1 1/2" or so to the end grain of the logs. I've seen a few of those.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Gabel]

#16173

07/12/08 08:32 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Gabel]

#16173

07/12/08 08:32 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I have seen very basic half lap joints, 2' long with 1-1/2" maple pegs, four of them per splice. One of the rare times I have seen hard wood used as pegging stock. The other place I have seen hard wood used is with a single peg, 1", shaved and tapered, red oak, at the dropped tie with a wedge, there was 8 of them in the whole frame, this is rare in my area. They looked much different than the spruce ones. Tim

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16178

07/13/08 11:16 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16178

07/13/08 11:16 PM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Hi I had a bin of pins laying around so here are some images of them. Near the center of the first photo is a 5/8" pin from a carrage shed. The others are typical, oak pins.   The short pin is 3" long and was holding a thin-wall type of frame together. Note the crooked point on a pin to the left. I did not have any other severly deformed pins... next time I will keep the bad pins I pull out of a frame just as examples.  Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16189

07/14/08 08:55 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16189

07/14/08 08:55 PM

|

Joined: Aug 2007

Posts: 21

Sussexoak

Member

|

Member

Joined: Aug 2007

Posts: 21 |

oak pegs of about 1/4 to 3/8 ths square were used extensively in Southern England to fix oak shingles onto timber spires.

They now use nail guns, but many oak pegs survive in the boarding.

So there are some historical uses for sheathing/roofing.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16190

07/14/08 09:30 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16190

07/14/08 09:30 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Jim, that's quite a collection... It would be neat to catalog the inventory to its perspective building. Have you done so? I know, we have lives, too, right? (wait a minute. this is our life!)

Sussexoak--

That's just what I'd been wondering about... "nailing" things on w/ treenails/pegs. It makes perfect sense that this was done. Can you get a picture sometime?

Boards/ sheathing must have been affixed this way, too.

How odd that they are square pegs! ...eaiser to produce, perhaps. Does this mean they went through a round hole?

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16206

07/15/08 09:07 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16206

07/15/08 09:07 PM

|

Joined: Aug 2007

Posts: 21

Sussexoak

Member

|

Member

Joined: Aug 2007

Posts: 21 |

Yes, square pegs in a round hole. They grip very well,abundant raw material, relatively quick and easy to produce, and durable.

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16415

08/04/08 01:39 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16415

08/04/08 01:39 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

Member

|

Member

Joined: Mar 2002

Posts: 1,198 |

Hello everyone

Relative to this topic on the use of wood pegs for unusual purposes, in the shoe making trade in the 18th century, the layers of leather for soles and attaching heels were fastened on with small wood pegs instead of tacks

NH

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: northern hewer]

#16416

08/04/08 11:31 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: northern hewer]

#16416

08/04/08 11:31 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

On a lighter side, didn't some pirates have peg legs? I bet the only shoe they had then used pegs, too. Tim

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16417

08/04/08 08:07 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16417

08/04/08 08:07 PM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Tim:

I believe pirates had "pin legs" !!

Sussex Oak:

Please post a photo of those pegs attaching the shingles-- or anything else... a remnant of a sipire post full of holes, etc. I'd love to see it.

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16422

08/05/08 09:14 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16422

08/05/08 09:14 AM

|

Joined: Aug 2007

Posts: 21

Sussexoak

Member

|

Member

Joined: Aug 2007

Posts: 21 |

Sorry not up to speed on posting photos yet.

But the oak pegs are square, 1/4 inch, and vary between 2 to 4" apart horizontally, and about 4" vertically, and protrude about 1/2 inch to 1 inch internally, and are perfect for catching old cobwebs!!!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16424

08/05/08 01:41 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16424

08/05/08 01:41 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Here is a couple of quotes from another thread that tells how to do pictures: Keep in mind a couple things when posting pics on the web:

Keep file size on the smaller size so that it uploads and downloads faster, and occupies less space. There are two ways to do this, resize the picture, or decrease the resolution. When you take a pic on your digital camera, the size is large and the resolution is high because you want high quality for printing. On the net, you don't anywhere near that high of resolution or size. I use a free program I downloaded off the web called Irfanview. It has an Image>resize command. I reduce it to the smallest standard size on there. Generally can get the file down to about 60KB, which is good for posting. Remember that when resizing, to keep the picture to a size that will fit on other peoples screen without them having to scroll to see it all.

So see how big your file size is, put your cursor over the picture file icon, right click and select properties.

Once you have sized your pic files, upload them to a picture site for hosting. I use picturetrail.com for about $20-30 a year. I think there are some free sites too, but I liked the picture trail options.

Once you have it hosted, simply open the picture, put your cursor over it and right click. You'll see the web address for the pic, copy that (highlight it and right click >copy). Then when you are in the forum post you can paste the address as a link, or use the forums image tags or link to past the address to post it as a picture instead of a link.

After you do this a couple of times, you'll see it's pretty easy. I like to up load multiple pics at once to save time. Happy posting. and: If you resize the photo to something like 800x600 it comes out the right size. And: And you don't have to slide the scroll bar left and right to see the whole picture.

The sites you store pictures on usually recommend that pictures are saved at about 800x600 for best Internet viewing.

Whatever you do, have fun doing it!

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16439

08/06/08 12:00 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: Sussexoak]

#16439

08/06/08 12:00 AM

|

Joined: Mar 2008

Posts: 570

OurBarns1

Member

|

Member

Joined: Mar 2008

Posts: 570 |

Sussexoak: If you don't want to post yourself, please send a pic to my email and I will post for us. Tim: I can see your picture! It came through.

Don Perkins

Member, TFG

to know the trees...

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16440

08/06/08 01:17 AM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: OurBarns1]

#16440

08/06/08 01:17 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I think I have it now. If I can do it Sussexoak can too. Jim recalled a size of 600x800 and FAQ's says 125x600. Is 600x800 OK? Tim

|

|

|

Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16447

08/06/08 02:37 PM Re: Pegs -- riven, sawn, drawn, turned, driven, et

[Re: TIMBEAL]

#16447

08/06/08 02:37 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

I use photobucket and they automatically resize to 800x600 when you upload to make it easy to post on threads.....

Whatever you do, have fun doing it!

|

|

|

|

|