I came across this description, thought it might help reinforce some of what we've been talking about.

Warp in lumber is any deviation of the face or edge of a board from flatness or any edge that is not at right angles to the adjacent face or edge (squares). It can cause significant volume and grade loss. All warp can be traced to two causes; differences between radial,tangential, and longitudinal shrinkage in the piece as it dries, or growth stresses. Warp is also aggravated by irregular or distorted grain and the presence of abnormal types of wood such as juvenile and reaction wood, Most warp that is caused by shrinkage difference can be minimized by proper stacking procedures (ch. 5). The effects of growth stresses are more difficult to control, but certain sawing techniques are effective and will be described

later.

The five major types of warp are cup, bow, crook, twist, and diamonding (fig. 8-11). Cup is a distortion of a board in which there is a deviation flatwise from a straight line across the width of a board. It begins to appear fairly early in drying and becomes progressively worse as drying continues. Cup is caused by greater shrinkage parallel to than across the growth rings. In general, the greater the difference between tangential and radial shrinkage, the greater the degree of cup. Thinner boards cup less than thicker ones. Because tangential shrinkage is greater than radial shrinkage,flatsawn boards cup toward the face that was closest to the bark (ch. 1, fig. 1-10). A flatsawn board cut near the bark tends to cup less than a similar board cut near the pith because the growth ring curvature is less near the bark. Similarly, flatsawn boards from small-diameter trees are more likely to cup than those from large-diameter trees. Due quartersawn boards do not cup. Cup can cause excessive losses of lumber in machining. The pressure of planer rollers often splits cupped boards. Cup can be reduced by avoiding overdrying. Good stacking is the best way to minimize cup.

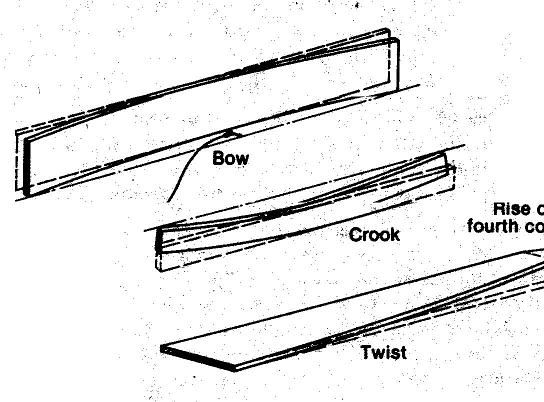

Bow is a deviation flatwise from a straight line drawn from end to end of a board. It is associated with longitudinal shrinkage in juvenile wood near the pith of a tree, compression or tension wood that occurs in leaning trees, and crossgrain. The cause is the difference in longitudinal shrinkage on opposite faces of a board. Assuming that there are no major forms of grain distortion on board faces, bow will not occur if the longitudinal shrinkage is the same on opposite faces.

Crook is similar to bow except that the deviation is edgewise rather than flatwise. While good stacking practices also help reduce crook, they are not as effective against this type of warp as they are against cup and bow.

Twist is the turning of the four corners of any face of a board so that they are no longer in the same plane. It occurs in wood containing spiral, wavy, diagonal, distorted,or interlocked grain. Lumber containing these grain characteristics can sometimes be dried reasonably flat by using proper stacking procedures. Twist, bow, and crook have definite allowable limits in the grading rules for softwood dimension lumber, so it is desirable to minimize these defects. Diamonding is a form of warp found in squares or thick lumber. In a square, the cross section assumes a diamond shape during drying. Diamonding is caused by the difference between radial and tangential shrinkage in squares in which the growth rings run diagonally from corner to corner. It can be controlled somewhat by sawing patterns and by air drying or predrying before kiln drying.

Boxed-Heart Splits

A boxed-heart split is shown in figure 8-8. These splits start in the initial stages of drying and become increasingly worse as the wood dries. The difference between tangential and radial shrinkage of the wood surrounding the pith causes such severe stresses in the faces of the piece that the wood is split. It is virtually impossible to prevent this defect.