|

Wood Behavior

#20845

08/05/09 05:14 PM Wood Behavior

#20845

08/05/09 05:14 PM

|

Joined: Nov 2006

Posts: 850

mo

OP

OP

Member

|

OP

Member

Joined: Nov 2006

Posts: 850 |

Hi There, Got a couple of question about green wood behavior. Thought this might start an interesting thread. Questions on checking, and bowing. Although checking is natural, and I have no problem with it, it seems that if the checking is predictable it might help me understand wood further.  These questions are based on all things being equal, such as the fortune of having the heart project all the way through the timber in the same point. I understand this could be a scenario that is not always possible. 1. Rectangular timber: Is the checking in this timber going to check on the two faces in the x-axis? If this is right, is the checking going to always start first at the face(s) closest to the heart? Could the checking also happen on the faces furthest from the heart (y-axis)? 2. Rectangular timber: The heart is closer to one face on the y-axis. Could this keep the face furthest from the heart from checking? Any possible bowing from this? 3. Offset heart: Face very close to heart. Which way is this baby going to bow? Like a "C" or "D" Has anyone heard of relieving grooves to negate checking? Alot of questions.

|

|

|

Re: Wood Behavior

[Re: mo]

#20847

08/05/09 07:17 PM Re: Wood Behavior

[Re: mo]

#20847

08/05/09 07:17 PM

|

Joined: Jan 2008

Posts: 918

bmike

Member

|

Member

Joined: Jan 2008

Posts: 918 |

I think you need to assume also that this timber is free floating in space, with no direct sunlight, and no heat reflecting surface from below or the sides. Sun exposure, air movement, and if it is stacked tight to other timbers (or a wall, ground, etc.) will affect the wet and dry sides...

I'm waiting for Don Ps. Insight here... as he'll throw down a good deal of knowledge if this interests him.

|

|

|

Re: Wood Behavior

[Re: bmike]

#20848

08/05/09 07:33 PM Re: Wood Behavior

[Re: bmike]

#20848

08/05/09 07:33 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

timbers usually check on the side the heart is closest to. Usually... A lot of mortices on another face could throw it that way. Or if the face closest to the heart is knotty, the path of least resistance may be towards another face.

And yes, I've heard of running a kerf down a non show face to throw the checks that way. Same principal as a control joint in concrete (it's gonna crack, so let's make it crack where we want it to.) Haven't done it, though.

As for bowing, I've not been able to see a correlation between heart location in the timber and direction of bow -- I just looked over our cull piles (plenty of bowed timbers) and noticed that they are going both toward and away from the heart. And I noticed that some of the timbers where the heart was only an inch or so from a face were dead straight.

|

|

|

Re: Wood Behavior

[Re: Gabel]

#20871

08/07/09 09:13 PM Re: Wood Behavior

[Re: Gabel]

#20871

08/07/09 09:13 PM

|

Joined: Nov 2006

Posts: 850

mo

OP

OP

Member

|

OP

Member

Joined: Nov 2006

Posts: 850 |

Thanks for the insight Gabel.

I think I'll try a dado for 12/2, and I'll report later.

Last edited by mo; 08/07/09 09:14 PM.

|

|

|

Re: Wood Behavior

[Re: mo]

#20877

08/08/09 02:31 PM Re: Wood Behavior

[Re: mo]

#20877

08/08/09 02:31 PM

|

Joined: Dec 2005

Posts: 574

Timber Goddess

Member

|

Member

Joined: Dec 2005

Posts: 574 |

Hi mo. Good topic  I like wood. 1. Most likely the timber will check on the x-axis, closest to the heart. Unlikely it will also check on the y after that, as the side checks will be pushing the wood together towards those faces (does that make sense? I'm kinda bad at descriptive writing...) 2. First part: yup, but never guaranteed. Second part: depends on way too many factors - drying conditions, species, how it was milled, how it was stacked...as Gabel mentioned, "I've not been able to see a correlation between heart location in the timber and direction of bow" 3. See 2, second part. The Japanese will kerf the tops of their timbers and then wedge them open to keep the visible faces from checking. It doesn't need to be too deep - an inch in a 10x is plenty. I have done this before - unfortunately I haven't seen the finished product, now about 3 years old. It would be cool to know whether the kerf has made a significant difference. We have sent some cedar and larch frames to Hawaii, and they would be checked when they left our shop, but after a few weeks on the Island, the checks would close up because of the moisture there. That's pretty cool... Keep in mind that I've worked mostly with DF,larch and cedar, not hard wood... Peace *K

|

|

|

Re: Wood Behavior

[Re: Timber Goddess]

#20882

08/09/09 03:02 AM Re: Wood Behavior

[Re: Timber Goddess]

#20882

08/09/09 03:02 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

I agree with everyone. All things being equal (uhhh, right) the check will take the shortest path from heart to face. If you remember the concentric rings of cells standing around the campfire analogy. As the cells lose moisture and pull together tighter, shoulder to shoulder, but are restricted to being able to move in only half as much as they shrink in shoulder to shoulder width this creates stress in the shoulder to shoulder connection. The weakest point in the circles is where we have cut more of the concentric rings away and that stress concentrates along the rays. When tension perp becomes greater than the strength of the wood a check forms. A check is sort of like a tear in a piece of cloth, the cloth absorbs and distributes your efforts until you get a tear started and then all your effort gets concentrated to that one area and it becomes quite easy to rip. Same with wood, it is worth taking pains to try to prevent checking whenever possible, much easier said than done. In piece 3 above the stick will likely bow like this ")" right off the mill due to growth stress. But assuming it doesn't, the larger proportion of juvenile wood on the right hand face will begin to shrink lengthwise as it dries, due to the off axis microfibril angle. As the right side shrinks it will try to pull the timber into this shape "(". There's several forces at work, that's why stating anything definitively is hard to do. Most forms of warp in straight grained wood after milling would be due to reaction wood either juvenile, compression wood or tension wood. Some exceptions that come to mind are cupping and slope of grain. That is all fine in a perfect world. There are branches, zones of reaction wood, slope of grain, spiral and any number of other variables in there. Everyone crowns horizontal wood up. We also like to have any knots near an edge up on the compression edge rather than down on the tension edge. Ever notice that you almost never can do that? The slope of grain around the knot pulls length out of that side as it dries, makes it shorter and that face becomes concave, the bottom. TG brings up a good point. I stickered a load of white oak boards onto the trailer right off the saw and drove out to deliver on a bright low humidity day. It was only a few miles but by the time I got there I had checked the mess out of the wood. By the time we had talked a few minutes and then unloaded, the checks were gone. I had dried the surface cells very rapidly and they shrank over the still swollen core until the shrinkage force exceeded the wood strength, and it checked. When I stopped, the high moisture of the wood's core re-equalized. Those surface cells swelled up, closing the checks. Looked ok at that moment, but I had torn the fabric. I had a kiln operator show me the same thing, wood with dirty streaks in it. In their yard as the checks were open the dust filtered in, when the checks closed the dirt was trapped.  This is a section I cut off a 6x6 post and noticed a few hours later, after it had dried. Since the length was not restrained the shrinkage was able to go into the third dimension rather than forming a check. Also notice the convex faces, the tangential grain shrinks more than the radial grain. Imagine what happens if I push down on the "tent", a check would have to form for it to lay flat, as it would in a timber of any length. Hopefully just showing another view of the stresses.

Last edited by Don P; 08/09/09 03:13 AM.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20883

08/09/09 04:12 AM Re: Wood Behavior

[Re: Don P]

#20883

08/09/09 04:12 AM

|

Joined: Apr 1999

Posts: 245

Tom Cundiff

Member

|

Member

Joined: Apr 1999

Posts: 245 |

Very well put Don. Thank you for that fine illustration of what' s going on with the stress in wood as it dries.

Not all who wander are lost.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20885

08/09/09 04:59 AM Re: Wood Behavior

[Re: Don P]

#20885

08/09/09 04:59 AM

|

Joined: Dec 2005

Posts: 574

Timber Goddess

Member

|

Member

Joined: Dec 2005

Posts: 574 |

This is a section I cut off a 6x6 post and noticed a few hours later, after it had dried. Since the length was not restrained the shrinkage was able to go into the third dimension rather than forming a check. Also notice the convex faces, the tangential grain shrinks more than the radial grain. Imagine what happens if I push down on the "tent", a check would have to form for it to lay flat, as it would in a timber of any length. Hopefully just showing another view of the stresses. This is a very cool explanation! Visual aides and metaphors really help the spacial thinkers... Thanks Don

|

|

|

Re: Wood Behavior

[Re: Timber Goddess]

#20886

08/09/09 10:48 AM Re: Wood Behavior

[Re: Timber Goddess]

#20886

08/09/09 10:48 AM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Great thread guys...and gal. I'm soakin it up!

Thane

Life is short so put your heart into something that will last a long time.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20887

08/09/09 03:53 PM Re: Wood Behavior

[Re: Don P]

#20887

08/09/09 03:53 PM

|

Joined: Nov 2006

Posts: 850

mo

OP

OP

Member

|

OP

Member

Joined: Nov 2006

Posts: 850 |

Hey Don, Very interesting stuff, thanks for taking the time to do that!

"In piece 3 above the stick will likely bow like this ")" right off the mill due to growth stress. But assuming it doesn't, the larger proportion of juvenile wood on the right hand face will begin to shrink lengthwise as it dries, due to the off axis microfibril angle. As the right side shrinks it will try to pull the timber into this shape "(""

I understand that this could probably be a question that leads to a complicated answer. But here goes.

Could you explain the growth stress factor? Does juvenile wood shrink longitudinally at a greater rate than the "mature" wood? And at what point does one submit to the other?

Although this theoretical it would be great if we could use this knowledge in a practical example. But like you said, there are a lot of other variables that are at work.

For instance say that "3" needs to be a post, with an interior brace. Could you rightly take what we have so far an orient it correctly (leading to a whole nother' discussion on "bowing: out or in"?

I don't know the strength of these forces in relation to joined material, but I wonder if we could realize that the post is going to bow in than the brace is in compression, but if it wanted to bow out, than this might not be as good, since we would be relying on a peg for tension. Is this last paragraph frivolous? I guess this last scenario depends on how long the timber takes to go from mill to bent....?

Sorry for all those questions ladies and gentlemen...

|

|

|

Re: Wood Behavior

[Re: mo]

#20888

08/10/09 01:01 AM Re: Wood Behavior

[Re: mo]

#20888

08/10/09 01:01 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

Sorry for what! A good question is what makes us think.

I'll tackle one,

This is a good read on growth stress;

http://www.fs.fed.us/ne/newtown_square/publications/technical_reports/pdfs/2004/316papers/Cassens1GTR316.pdf#search='tension%20growth%20stress%20tree%20checking'

|

|

|

Re: Wood Behavior

[Re: Don P]

#20901

08/11/09 11:36 AM Re: Wood Behavior

[Re: Don P]

#20901

08/11/09 11:36 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

These are a couple of short articles on juvenile wood; http://www.fpl.fs.fed.us/documnts/techline/properties-of-juvenile-wood.pdfhttp://www.fpl.fs.fed.us/documnts/rips/fplrip-4701-001-western-juvenile-softwoods.pdf I'm working on a deck repair, this is one of the old deck boards that I skimmed 1/16" off of. You can see the heart. Juvenile wood shrinks lengthwise far more than normal wood. When it is surrounded by mature wood that does not shrink appreciably lengthwise it often checks crossgrain when the stresses exceed the strength of the wood. Just below the reddish heartwood is a band of what I call "peanut butter" looking grain. It is duller and lifeless looking compared to normal latewood. That's compression wood. Bad microfibril angle and loaded with lignin. It is stiffer than normal but weaker. I've caught myself using it for scaffold planks because it is heavy and stiff, it'll fool ya! It's weaker and breaks short, without warning.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20908

08/11/09 11:44 PM Re: Wood Behavior

[Re: Don P]

#20908

08/11/09 11:44 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I have some cedar deck boards with the same pattern, right down the pith. Now I know why. Thanks Don P.

Tim

|

|

|

Re: Wood Behavior

[Re: TIMBEAL]

#20910

08/13/09 01:31 AM Re: Wood Behavior

[Re: TIMBEAL]

#20910

08/13/09 01:31 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

Thanks for reading, I was starting to get lonely there  If unrestrained it would tend to cause the board to bow as it dries and shrinks,  If on an edge it would tend to cause crook. Growth stress on the board above should have made it want to bow away from the bark but the juvenile core made it bow toward the heart. This is another pair of good articles on growth stress, juvenile wood, checking, etc. One on hardwoods and one on softwoods; http://www.fpl.fs.fed.us/documnts/pdf1987/maegl87a.pdfhttp://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr129.pdf

|

|

|

Re: Wood Behavior

[Re: Don P]

#20911

08/13/09 10:32 AM Re: Wood Behavior

[Re: Don P]

#20911

08/13/09 10:32 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

A few post back there was a few comments where folks have said they have not seen the pith location effect bow in a timber. I am guessing with larger dimension stock has enough structure to over compensate the juvenile core. On boards there is less surrounding structure and the core has a bigger effect.

Tim

|

|

|

Re: Wood Behavior

[Re: TIMBEAL]

#20917

08/14/09 10:48 AM Re: Wood Behavior

[Re: TIMBEAL]

#20917

08/14/09 10:48 AM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

I would agree, that is part of it, in these last few posts I've also been picking southern pine to show the reaction wood because it has the most I've come across and is pretty easily visible. Eastern White Pine by comparison generally just lays there, its generally pretty stable stuff. The growth stresses in poplar can cause it to split right off the saw but I can't recall a juvenile bow in a stick of it. Red oak I've seen go both ways. Nature is complex and full of unique individuals. I have seen several cases of 6x8 and 8x8 milled logs (which are just boxed heart timbers) where the logs have shrunk lengthwise, leaving a gap in a butt joint in a wall of rows of timbers. Several times in "mixed southern pine" and once in western red cedar.

Going back to a comment on my white pines, the juvenile core can be a foot in diameter, so the wood in it would be weaker than one might expect if the juvenile core was small. By contrast if I let them continue to grow and each year they continue to put on 1/4", it will now be putting that 1/4" of mature wood on a larger cylinder... many more bf of mature wood per year. This might be good for boards but for timbers a compact heart might be a better thing to look for.

With boxed heart around the core hopefully the juvenile wood is encased within a healthy shell of mature wood. Then the reaction wood is in the neutral axis of a beam where stresses are low.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20919

08/15/09 12:19 AM Re: Wood Behavior

[Re: Don P]

#20919

08/15/09 12:19 AM

|

Joined: Feb 2006

Posts: 718

Dave Shepard

Member

|

Member

Joined: Feb 2006

Posts: 718 |

Interesting points regarding the juvenile wood in ewp. I cut a frame last fall, and the timbers were quite manageable. The timbers in last weeks workshop, also ewp, were much heavier. I know my trees came from an area that would have encouraged fast growth. I'm thinking that the trees in last weeks workshop must have been much slower growing.

Member, Timber Framers Guild

|

|

|

Re: Wood Behavior

[Re: Dave Shepard]

#20920

08/15/09 05:27 PM Re: Wood Behavior

[Re: Dave Shepard]

#20920

08/15/09 05:27 PM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

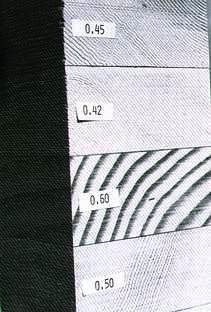

In softwoods density is somewhat independent of rate of growth. This is a picture that shows dougfir labelled with the specific gravity of each piece. The percentage of latewood is a better indicator of density than rate of growth.  Going back to my little stand of pines, I need to go in and take out the supressed trees. These are now in the understory and will have as many rings as the big boys but are a fraction of the diameter. My guess is they will have been starved of light and nutrients so will be slower grown, with a small juvenile core. But I'll bet it will be unusually light with little latewood. I expect it will be fairly stable wood since density is one thing that causes shrinkage, light low density wood doesn't shrink as much in the same species as a denser piece but is weaker.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20921

08/15/09 05:35 PM Re: Wood Behavior

[Re: Don P]

#20921

08/15/09 05:35 PM

|

Joined: Jan 2007

Posts: 217

Don P

Member

|

Member

Joined: Jan 2007

Posts: 217 |

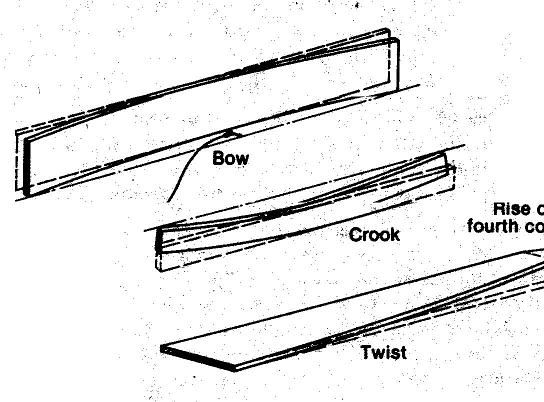

I came across this description, thought it might help reinforce some of what we've been talking about. Warp in lumber is any deviation of the face or edge of a board from flatness or any edge that is not at right angles to the adjacent face or edge (squares). It can cause significant volume and grade loss. All warp can be traced to two causes; differences between radial,tangential, and longitudinal shrinkage in the piece as it dries, or growth stresses. Warp is also aggravated by irregular or distorted grain and the presence of abnormal types of wood such as juvenile and reaction wood, Most warp that is caused by shrinkage difference can be minimized by proper stacking procedures (ch. 5). The effects of growth stresses are more difficult to control, but certain sawing techniques are effective and will be described later.   The five major types of warp are cup, bow, crook, twist, and diamonding (fig. 8-11). Cup is a distortion of a board in which there is a deviation flatwise from a straight line across the width of a board. It begins to appear fairly early in drying and becomes progressively worse as drying continues. Cup is caused by greater shrinkage parallel to than across the growth rings. In general, the greater the difference between tangential and radial shrinkage, the greater the degree of cup. Thinner boards cup less than thicker ones. Because tangential shrinkage is greater than radial shrinkage,flatsawn boards cup toward the face that was closest to the bark (ch. 1, fig. 1-10). A flatsawn board cut near the bark tends to cup less than a similar board cut near the pith because the growth ring curvature is less near the bark. Similarly, flatsawn boards from small-diameter trees are more likely to cup than those from large-diameter trees. Due quartersawn boards do not cup. Cup can cause excessive losses of lumber in machining. The pressure of planer rollers often splits cupped boards. Cup can be reduced by avoiding overdrying. Good stacking is the best way to minimize cup. Bow is a deviation flatwise from a straight line drawn from end to end of a board. It is associated with longitudinal shrinkage in juvenile wood near the pith of a tree, compression or tension wood that occurs in leaning trees, and crossgrain. The cause is the difference in longitudinal shrinkage on opposite faces of a board. Assuming that there are no major forms of grain distortion on board faces, bow will not occur if the longitudinal shrinkage is the same on opposite faces. Crook is similar to bow except that the deviation is edgewise rather than flatwise. While good stacking practices also help reduce crook, they are not as effective against this type of warp as they are against cup and bow. Twist is the turning of the four corners of any face of a board so that they are no longer in the same plane. It occurs in wood containing spiral, wavy, diagonal, distorted,or interlocked grain. Lumber containing these grain characteristics can sometimes be dried reasonably flat by using proper stacking procedures. Twist, bow, and crook have definite allowable limits in the grading rules for softwood dimension lumber, so it is desirable to minimize these defects. Diamonding is a form of warp found in squares or thick lumber. In a square, the cross section assumes a diamond shape during drying. Diamonding is caused by the difference between radial and tangential shrinkage in squares in which the growth rings run diagonally from corner to corner. It can be controlled somewhat by sawing patterns and by air drying or predrying before kiln drying. Boxed-Heart Splits A boxed-heart split is shown in figure 8-8. These splits start in the initial stages of drying and become increasingly worse as the wood dries. The difference between tangential and radial shrinkage of the wood surrounding the pith causes such severe stresses in the faces of the piece that the wood is split. It is virtually impossible to prevent this defect.

|

|

|

Re: Wood Behavior

[Re: Don P]

#20924

08/16/09 04:20 PM Re: Wood Behavior

[Re: Don P]

#20924

08/16/09 04:20 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Great info Don, thanks.....

Whatever you do, have fun doing it!

|

|

|

|

|