|

6 basic assemblies

#21360

10/15/09 12:05 AM 6 basic assemblies

#21360

10/15/09 12:05 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Is anyone interested in discussing the basic ways a tie beam relates to the plate such as normal, reverse, and level assembly, dropped tie including necked tie beams, interrupted plate, and double tie beams?

This would require scaning in some sketches or photos to be clear.

Why does this interest you?

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21362

10/15/09 03:53 AM Re: 6 basic assemblies

[Re: Housewright]

#21362

10/15/09 03:53 AM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Jim, Count me in. Your terminology with pictures would help. I'd be glad to, but my picture taker is broken.

I think you are on to something that all of us could learn from. If we get this started it might catch up with "Historic Hewing Questionaire".............

Edit. Forgot to answer your question. Because it is the timberframing question.

Last edited by mo; 10/15/09 03:54 AM.

|

|

|

Re: 6 basic assemblies

[Re: mo]

#21364

10/15/09 07:42 AM Re: 6 basic assemblies

[Re: mo]

#21364

10/15/09 07:42 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Jim,

What's on your mind ?

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: 6 basic assemblies

[Re: Ken Hume]

#21365

10/15/09 09:51 AM Re: 6 basic assemblies

[Re: Ken Hume]

#21365

10/15/09 09:51 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Yes, one at a time please.

Because I can find my self falling into a rut and using just a couple of tie set-ups, and that is limiting, so a variation on a theme will open doors and allow a more creative frame.

My picture taker is broken too, shimming up a rafter and the screen broke, it will still take a picture but it is a guess.

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21368

10/15/09 12:28 PM Re: 6 basic assemblies

[Re: TIMBEAL]

#21368

10/15/09 12:28 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

I'm interested as well.....

Whatever you do, have fun doing it!

|

|

|

Re: 6 basic assemblies

[Re: Jim Rogers]

#21376

10/15/09 07:00 PM Re: 6 basic assemblies

[Re: Jim Rogers]

#21376

10/15/09 07:00 PM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Count me in boys. I've only been using one style and don't even know what to call it. I just know it's a Tie Beam used in local barn frames.

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21379

10/15/09 10:34 PM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21379

10/15/09 10:34 PM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Hi Guys;

The six catagories I listed in the first post are all I know of so I will be interested to see if there are any others.

I will see if I can digitize some drawings from Historic American Timber Joinery: A Graphic Guide.

Taking one at a time, normal assembly is called that because it was so common, at least in England and before the mid 19th century in N. America. The English tying joint is a well known example, where the tie beams sit over the plate. This is an inherently good designn because the rafters land directly on the tie and form a triangle.

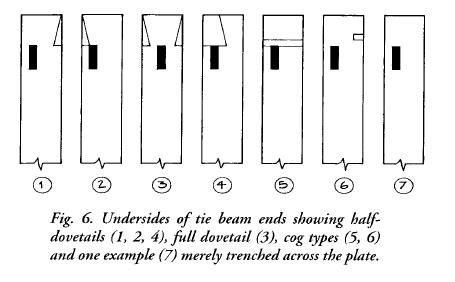

The types of notches used to restrain the plate and tie does not matter in calling this assembly normal, but an English tying joint always has a dovetail or half-dovetail and the tie is usually let into the plate 1.5 to 2 inches. The Germans seemed to use a cog, and in some normal assemblies the top of the tie and plate are flush.

If you have Historic American Timber Joinery, see page 10 for seven examples of notches that join ties to plates found in the USA.

Jim

Last edited by Housewright; 10/15/09 10:36 PM. Reason: typo

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21380

10/16/09 12:37 AM Re: 6 basic assemblies

[Re: Housewright]

#21380

10/16/09 12:37 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

I'll try to play in also Jim -

Why, because I've had the good fortune to see or even work on most of the variants on the list, that and I'm curious to see where the discussion goes.

Don't have HATJ with me, but there's alot I don't have with me...

|

|

|

Re: 6 basic assemblies

[Re: Will Truax]

#21381

10/16/09 12:42 AM Re: 6 basic assemblies

[Re: Will Truax]

#21381

10/16/09 12:42 AM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Do Collar Ties fit in here also or did you already list it by some other name?

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21382

10/16/09 09:21 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21382

10/16/09 09:21 AM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

For those of you who don't own the printed book of joints known as the "Historic American Timber Joinery" (HATJ) you can download free pdf copies from the guild site. Here, I believe is the figure that Jim is referencing:

Whatever you do, have fun doing it!

|

|

|

Re: 6 basic assemblies

[Re: Jim Rogers]

#21383

10/16/09 10:34 AM Re: 6 basic assemblies

[Re: Jim Rogers]

#21383

10/16/09 10:34 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I have switched to using cogs in the normal assembly. I think it was the perceived difficulty of cutting the half dovetails in the end bents that first drove me in that direction. I get turned inside out very easily and the cog, in my eyes, is an easier joint for me to figure, I also like how they are cut, no finicky corners to deal with.

Typically principal rafters and common purlins are used but I have seen common rafters and principal rafters used, I see this could apply additional forces on the dovetail and the cog. Which joint would work best to resist these forces?

Raising is also a deal. In a large building you need a larger crew to stand the long walls up and the difficulty of assembling the truss or a large gin pole set up to get it up in place. Of course with todays technology it is no problem. I have read this is part of the reason they switch to bent raisings it makes for a more friendly raising. And a segway to other tie configurations but let's not go there yet.

Tim

Last edited by TIMBEAL; 10/16/09 10:36 AM.

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21387

10/16/09 02:39 PM Re: 6 basic assemblies

[Re: TIMBEAL]

#21387

10/16/09 02:39 PM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

I am almost finished cutting the joinery for a covered porch. This will be for my house. I tried something different with the Tie Beam as it was going to be too low if I made it the standard below the plate method. I'm not sure if it was applied correctly but it should be plenty strong.  What would you call this Tie Joint as it is different at each end.

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21393

10/16/09 11:48 PM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21393

10/16/09 11:48 PM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Hi Will and Everybody; Thane, collars do not affect this discussion, that I can think of. But, while we are on the subject, collars are normally in compression to try not to call them a tie. The only time they are designed to be ties are when they are near the bottom of the rafters, usually they are half of two-thirds the way up the rafters and keep the rafters from sagging rather than spreading. I would call your porch frame assembly "Thane's Assembly"!! I like it. The tapered or gunstock posts in old frames in the North always taper into the building in the direction of the tie, but in the South, sometimes they put the taper in the direction of the plate like you did. Since your rafters are supported at both ends there will be no outward rafter thrust so maybe I wouldn't even call any timber in your frame a tie...."Tieless Assembly"! Sort of like a hammerbeam truss! Thanks Jim, I did not know HATJ was on the web. Yes I was referring to that drawing. Here is a link: http://www.tfguild.org/joinery/part2.pdfBy the way, if anyone sees joiinery which is not in HATJ, let Jack know so he can add it in the next edition. I think he has about 13 more joints to add. Tim, I know dovetails are very strong but they allow some slippage as they shrink. I do not know how strong a cog is. This is a good engineering question which would depend on the wood species, size of the cog, roof load etc. Here is a normal assembly barn which was taken down after a wind storm blew a rotten gable end completely off. It had common and principle rafters which tenon into a five-sided ridge. The beam directly below the tie is a binding beam. This barn was one of two 40' x 40' barns next to each other on a farm of German-American decent here in Waldoboro, Maine.  Here is a normal assembly house frame in Waldoboro, Maine with the tie and plate flush and an "eaves purlin" tenoned into the ties.  Jim

Last edited by Housewright; 10/16/09 11:53 PM. Reason: added info

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21394

10/17/09 12:16 AM Re: 6 basic assemblies

[Re: Housewright]

#21394

10/17/09 12:16 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

I tried editing but ran out of the time limit and then the edit button dissapeared. Sorry about the typos in the last post.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21395

10/17/09 12:17 AM Re: 6 basic assemblies

[Re: Housewright]

#21395

10/17/09 12:17 AM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Jim

In the Collar Tie frame I am refering to the Collar tie is located near the bottom and the end brace extends from the post to the collar tie. In this example the collar is indeed in tension and is hold things together. Even though it may not be part of this disscusion I thought it worth mentioning. Keeping in mind I am building smaller structures.

I did have a look at the on-line book of Historic American Timber Frames and am looking forward to some lively debate.

Thane

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21398

10/17/09 08:54 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21398

10/17/09 08:54 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Jim,

I find it hard to believe that a barn in such good condition as per your photos could have been allowed to be pulled down.

Why was the gable end not just repaired and placed back in position ?

Regards

Ken Hume

Looking back to see the way ahead !

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21399

10/17/09 10:36 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21399

10/17/09 10:36 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Jim

In the Collar Tie frame I am referring to the Collar tie is located near the bottom and the end brace extends from the post to the collar tie. In this example the collar is indeed in tension and is hold things together. Even though it may not be part of this discussion I thought it worth mentioning. Keeping in mind I am building smaller structures.

Thane Hi Thane, could you clear this up a bit? Are you referring to the depiction you posted or another one, if another could you post that picture? It sounds of interest. Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21400

10/17/09 11:48 AM Re: 6 basic assemblies

[Re: TIMBEAL]

#21400

10/17/09 11:48 AM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Tim & Jim Here is an example I am refering to. Though I think the king post may have an affect on this one.  I appoligize for straying from the original topic of the six Tie connections.

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21404

10/17/09 03:52 PM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21404

10/17/09 03:52 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Jim,

That is a great picture of the normal assembly. On that post I can't tell if it is checking or actually splitting from shear forces. If it splitting, could it be because the thrust from the rafters between the bents is causing the dovetail to slip (this could be from the ridge falling)?

The tie does have a dovetail on it right, or is there another connection from tie to plate? I could look up in my yellow book, but I have lent it out to some architects for their referencing.

ASIDE ROOF FRAMING: Is there any reason that the builders would not have used a purlin system into the principal rafters? Would this not reduce the thrust? Do you think they did not have the proper material for such a set up?

Last edited by mo; 10/17/09 03:53 PM.

|

|

|

Re: 6 basic assemblies

[Re: mo]

#21408

10/17/09 05:08 PM Re: 6 basic assemblies

[Re: mo]

#21408

10/17/09 05:08 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I see the check as a natural formation, it easily runs down the post from the square corner which the top plate sits in, many are like this. I also see the principal rafters holding up the majority of the roof, it is a complete unit. If you were to cut the boarding right at the principal rafters and disconnect them from the unit I could see thrust being applied to the walls. I also suppose the bay spacing could have an impact on this as well. Think of it this way if the check was due to thrust we wouldn't be looking at a picture of it now, a crack that long would not be much good with some thrust on it.

As for purlins, it could be a time issue, simpler to install rafters, the frame seem to be square ruled? and purlins were more commonly let in to the tops of the rafters and scribed. It is a newer barn and newer approaches to framing were used. It may even have been reworked 100 years ago, I am starting to guess now.

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21411

10/17/09 06:22 PM Re: 6 basic assemblies

[Re: TIMBEAL]

#21411

10/17/09 06:22 PM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

This crack may well have started as a check but but was encouraged by the thrust from the common rafters at the sides. If it is a dovetail conection at the Tie/plate then you would get some give in the first weeks after assembly as a result of some slack in the fit as well as compression. This could be as much as 1/3rd of it's total movement. In the years following as the dovetail dries and shrinks, the plate would then be allowed to further separate. On the bottom of the Tie at the back side of the post there seems to be a rather large gap in the mortise suggesting perhaps the inside portion of the post has been pulled out. I am puzzled why I don't see any pegs at that post to Tie M/T.

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21412

10/17/09 07:17 PM Re: 6 basic assemblies

[Re: Housewright]

#21412

10/17/09 07:17 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Jim, about joinery. I have showed these before, but I don't recall seeing them in HATJ. Forward if you like and I'm pretty sure I can go back and get specs on them if needed.

|

|

|

Re: 6 basic assemblies

[Re: mo]

#21414

10/17/09 08:54 PM Re: 6 basic assemblies

[Re: mo]

#21414

10/17/09 08:54 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Thane, it could be that there is not a peg, compression is all that is needed at that point. Or a blind hole, we are looking at the non reference face It is hard to tell but is there a mortice showing on the bottom of the tie just to the inside of the post?

It looks like the top plate may be rolled a bit, but it is still reasonably close at the bottom to the plate next to the post. What does the post look like from the reference face, the door side?

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21415

10/17/09 09:47 PM Re: 6 basic assemblies

[Re: TIMBEAL]

#21415

10/17/09 09:47 PM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Tim, the Teasels most definitely should be pinned - A high wind on a broadside could see the braces on the leeward side go into enough compression that they could potentially overcome the weight of the roof and jack the ties up higher than the depth of the dovetails or cogs, and spit the wall right off the building.

Not much likelihood of just the right array of nastiness lining up just so and seeing that happen, but while I do sometimes skip pegging joints that never go into tension, this isn't one to skimp on.

|

|

|

Re: 6 basic assemblies

[Re: Will Truax]

#21416

10/17/09 10:39 PM Re: 6 basic assemblies

[Re: Will Truax]

#21416

10/17/09 10:39 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

So it is most likely a blind hole. Yes, just the simple force of the braces with a wind on one side would pry the joint. A one hundred year storm.

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21417

10/18/09 12:19 AM Re: 6 basic assemblies

[Re: TIMBEAL]

#21417

10/18/09 12:19 AM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

Does anyone have any suggestions as to how this joint may have been improved so that it would not have failed like it did?

Without changing the rafter concept.

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21418

10/18/09 01:23 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21418

10/18/09 01:23 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Thane, I should have mentioned that I study historic carpentry and the catagories of assemblies I listed in the beginning are for historic frames. I find your contemporary designs interesting and add complexity to trying to catagorize this connection. Your designs also show how "traditional timber framing" is not entirely traditional and we are no longer constrained to designs from the past or to working in any one style of framing all of our careers.

Ken, there is more to the story of this barn. Several years ago the owners decided they could not afford to maintain the seven remaining farm buildings on the property so they sold salvage rights to one of the two barns to a antique lumber dealer. The dealer improperly took the wall boards of the second barn and would not return them. He was taken to court and lost and is supposed to be making payments on the damages which is an ongoing struggle to collect. The owners had the barn reboarded with new boards and I think the studs were added then. There were other rotten areas of the barn and foundation work was needed. They chose not to put more money into this building, but they are maintaining four or five of the other outbuildings.

This farm complex dates from the 1790s.

I do not know if the post is checked or split. I have seen a gunstock post split from rafter thrust when after the roof system of a barn had been changed to a ccommon rafter system and put significant outward thrust onto the plate. This check/split could be either, though I doubt there was excessive rafter thrust on the plate in this design since the ridge beam acts as a supporting ridge transferring some load to the principle rafters.

There are pegs in the rafter feet and tie/post connections. The layout face is the drive floor and the pegs are, as usual, driven from the layout face. They certainly are not clear in the photo.

Mo, I do not see the exact joint in your photo in HATJ, but Jack does not have a computer so I cannot "forward" it. I would send it to him if you email me more specifics about the building at jim.derby@hotmail.com.

I also should mention that the tie/plate joint on my second image is a simple half lap which is not shown in the drawing Jim Rogers posted for us.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21419

10/18/09 12:59 PM Re: 6 basic assemblies

[Re: Housewright]

#21419

10/18/09 12:59 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Will, I recall seeing such a joint with no pegging and have been through my photos but with no result. It clearly should be pegged but there have been frames assembled with out the the peg, inferior for sure, my question would be, does this frame have a peg or not. I peg all mine and rarely do I not peg most joints.

My statement of compression holding the joint was weak, I had a moment of absence.

I do feel that the joint, pictured, on the whole, is still strong.

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21429

10/19/09 12:54 AM Re: 6 basic assemblies

[Re: TIMBEAL]

#21429

10/19/09 12:54 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Onward to reverse assembly which is simply when the plate is on top of the tie. This is described as being "more ancient" than normal assembly by Mr. Brunskill.

The plate on top means the frame needs to be raised in bents rather than raising the sidewalls as in normal assembly; an advantage in long barns.

One use of this type in the U.S.A. is in Swisser or Sweitzer barns in parts of Pennsylvania. As the name implies, these barns are of Swiss origin, but are often built by Pensylvania-Germans called Pensylvania-Dutch, a corruption of Deutsch the name Germans call themselves.

Robert Ensminger is one of the only people who have provided written material on this type in his book The Pennsylvania Barn, pages 250-253. Here he describes turning the outside posts one-quarter turn and replacing the plate tenon with a slot for the necked down tie to slip into. The local name for this is esel fuus or mule's foot joint. This is the joint I refered to in the beginning of this thread as "slotted post", so maybe it should fall under the reverse assembly label.

I cannot find the photo I have of a turned gunstock post so I will have to keep looking.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21431

10/19/09 02:25 AM Re: 6 basic assemblies

[Re: Housewright]

#21431

10/19/09 02:25 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

Jim - I'm away from my library, What regions of PA are Sweitzers' found in ? Wondering if I'm near any.

Tim - Do know my intent was not so much to edify you as it was just that I thought it important to make it clear to all that ever happen by this thread, that teasles need be pegged.

Mo - Where is that roof system in your photographs ?

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21434

10/19/09 09:43 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21434

10/19/09 09:43 AM

|

Joined: Mar 2002

Posts: 961

Ken Hume

Member

|

Member

Joined: Mar 2002

Posts: 961 |

Hi Jim, I thought that you might like to see a logical progression of the failure of a tieing joint as per Thane's post after a period of 684 years in service :- The main reason that this building is still standing is that there is another building butting hard up against the sidewall preventing any further movement. It would appear once again that providing secondary lines of defence can head off catastrophic failure in a building. To get a measure of scale please note that the cross brace is about 9" wide and 8" thick. .jpg) Regards Ken Hume

Looking back to see the way ahead !

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21435

10/19/09 12:33 PM Re: 6 basic assemblies

[Re: Housewright]

#21435

10/19/09 12:33 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Here is a normal assembly house frame in Waldoboro, Maine with the tie and plate flush and an "eaves purlin" tenoned into the ties.  Jim [/quote] Before we move on, for clarity is the tie in this picture pegged to the post via a teazle tenon? If it is what I think it is there is nothing holding it down but gravity. The post is tenoned into just the top plate only, a good chance it is not even spiked. It does have to lift 4" or so to come apart. There is also sheathing and studs which will have to be over come to fail due to wind and the prying action on the gable ends. I am going to be using this type of joinery on the addition here at my house. The addition is between two structures, similar to Ken's latest mention of additional supportive structures. The wall system will be of 2" plank and a limited number of post, at least 4, one in each corner, maybe one set in the middle or other convenient location, this is over 43'. Ken has brought up numerous times load paths and of ways to re directing forces in leggy structures. Will Beemer's recent article in Fine Homebuilding also mentions sips add strength to hybrid buildings. Once looking at the structure as a whole it becomes stronger than if it is looked at individually. I once had an architect go through extreme measures to fabricate a hold down system for the post to foundation connection all the while paying no attention to the single peg at the teazle tenon which was the only thing other than gravity holding down the roof. Tim

|

|

|

Re: 6 basic assemblies

[Re: Will Truax]

#21437

10/19/09 02:33 PM Re: 6 basic assemblies

[Re: Will Truax]

#21437

10/19/09 02:33 PM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Hi Will - Sweitzers are "the original Pennsylvania barn", originally log then frame and stone or brick, built from 1730 to 1850 in the "barn core region" which is from the northern line of Bucks County to Washington County, MD. Also described as being centeral and south eastern PA. Look for 12:12 pitch saltbox like forebay barns with 6 to 9 foot unsupported forebays. PA barns is a large subject so this is a simplification. Many frame drawings in Ensminger's book show a tie over the plate and another dropped tie up to 4' below the plate, low enough to get a brace into the upper tie.

The one photo of a double tie which sandwiches the plate is from near Mt. Holly, Cumberland County, PA. These "headed tie beams" occure in centeral and western PA into eastern Ohio. The heads of these ties project outside the sheathing at the eaves so this type is identifiable from the road.

Tim - the photo you asked about is of the house you looked at with me in Waldoboro. The one with "thinwall framing" where the corners were a 3x9 and a 3x6 pinned together to make an L. There was were pinned tenons going into both the plate and tie.

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Will Truax]

#21438

10/19/09 03:19 PM Re: 6 basic assemblies

[Re: Will Truax]

#21438

10/19/09 03:19 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

ASIDE: Will T, First Scotts, Library of Congress Brief Description It would take more research to find out if any of the timberwork has been restored. Big earthquake in 1886, but I bet the timber did a dance with it and most of the restoring was with the masonry.

Last edited by mo; 10/19/09 03:22 PM.

|

|

|

Re: 6 basic assemblies

[Re: mo]

#21444

10/19/09 11:51 PM Re: 6 basic assemblies

[Re: mo]

#21444

10/19/09 11:51 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Yes I recall it Jim.

I also went back to the frame which has me on this topic and viewed it to refresh my mind. It is also 43' long and only the corner post have teazle tenons. All the rest down the wall have none, they are space about 8' apart, with just a half lap.

Tim

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21486

10/22/09 12:38 PM Re: 6 basic assemblies

[Re: Housewright]

#21486

10/22/09 12:38 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

The one photo of a double tie which sandwiches the plate is from near Mt. Holly, Cumberland County, PA. These "headed tie beams" occure in centeral and western PA into eastern Ohio. The heads of these ties project outside the sheathing at the eaves so this type is identifiable from the road.

Jim

Jim, I have never seen even a picture of this double tie. Any one have a picture? Were shear blocks used as well? What was the configuration of post under this? Why did they use such a thing? Were they trying to span larger distances, hence the shear block question? Could it be a fall back to log construction? Were these timbers salvaged from log barns, as in the case with some fore bay barns? Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21509

10/22/09 04:52 PM Re: 6 basic assemblies

[Re: TIMBEAL]

#21509

10/22/09 04:52 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Here's a necked tie beam from a humpty dumpty barn from PA we were hired to put back together down here in GA. The tie dropped down onto the post tops through a through mortise that extended tot he top of the post and then the plate dropped on after that. This would be reverse assembly, I suppose, as the bents were the sections that were preassembled and raised and the plates were dropped on after. Wish I had a better photo of it. It is very similar to Fig. 17 on page 7 of HATJ.  dropping the plate on.  view of assembled joint.

|

|

|

Re: 6 basic assemblies

[Re: Gabel]

#21510

10/22/09 05:04 PM Re: 6 basic assemblies

[Re: Gabel]

#21510

10/22/09 05:04 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Modern ETJ with jetty. THese are the 2nd level (1st floor if your English, 2nd for us Americans)posts rising from the jetty to the top plate. Same joint on both ends.  Same building...  And again...

|

|

|

Re: 6 basic assemblies

[Re: Gabel]

#21511

10/22/09 06:26 PM Re: 6 basic assemblies

[Re: Gabel]

#21511

10/22/09 06:26 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Gabel, That is one awesome piece of architecture!

Maybe a little off topic (Sorry Jim), but I have to ask a couple of questions..

Whats the wood species?

What's the infill?

Did you all orient any particular face characteristics to the weather? What means were used to have that exposed timber last?

Seeing the frame from the outside is really nice.

|

|

|

Re: 6 basic assemblies

[Re: Ken Hume]

#21519

10/23/09 12:38 PM Re: 6 basic assemblies

[Re: Ken Hume]

#21519

10/23/09 12:38 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Ken,

It was our contract. However, Jordan was hired on for the job as a sub-contractor.

|

|

|

Re: 6 basic assemblies

[Re: mo]

#21520

10/23/09 12:57 PM Re: 6 basic assemblies

[Re: mo]

#21520

10/23/09 12:57 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Mo,

Thanks, mo it was a nice project.

Keeping the hijack brief...

-white oak

-fiber cement backer board grooved into the sides and bottoms of all timbers with backer rod in the groove. Render (basically stucco) on that with permachink at all edges of the panels. Inside the FC panel, insulation, DW, and plaster. Only posts, plates, window studs, and window cills show inside. Not our design, but we did groove all the studs, posts, and plates and scribe each FC panel as we built each frame and install them as the frame went up.

-Tried to turn sapwood in, but couldn't always.

-All exposed sapwood was treated with a borate product (name escapes me). Not sure if anything more was done by others.

End of hijack.

|

|

|

Re: 6 basic assemblies

[Re: Gabel]

#21733

11/11/09 01:23 AM Re: 6 basic assemblies

[Re: Gabel]

#21733

11/11/09 01:23 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

There is more information about reverse assembly frames in the U.S.A. in the works. On to dropped tie framing, also known as H-bent framing. This type is very common in Dutch-, German- and English-American buildings. John Stevens mentioned in his book Dutch Vernacular Architecture in North America, 1640-1830 that H-bent framing originated in Germany, but is characteristic of Dutch-American buildings. Maine is loaded with dropped tie buildings sometimes with the large posts and close spacing in the Dutch style. The tie beam is usually joined to the post with a wedged half-dovetail joint anywhere from six inches to more than ten feet below the rafters in the case of anchor beam barns. I find that the plates in buildings with the tie dropped more than about two feet often bow outward. The posts often bow, also. Below is a image of a poorly designed dropped tie where the tie and braces landed in the same part of the 6" x 6" post leaving very little strength to resist the outward thrust of the rafters. Two of the posts broke at this joint. Note the iron dog helping to hold the joint together.  Here is my house, possibly built in 1851 in Waldoboro, Maine. There is a board shelf from the plate to the interior wall, if you are wondering what "that thing" is. The 4" x 6" tie beams are the floor joists and run the full width of the house (about 25 feet) supported by the vertical planks that form the interior walls, a typical detail for houses around here:  My house has iron tie rods near the middle to help the plate from bowing outward, they may help but the walls still bow a few inches even with a half-pitch roof. The tie rod is near the vertical sewer vent pipe and wraps around a large hand-spike in the tie (image from before restoration).  Sometimes wood braces with a lapped half-dovetail are used like the iron tie rod to help prevent the plates from bowing. I have not noticed anyone calling an anchor beam a dropped tie, but to me it is. Anchor beams are dropped so far I doubt they are effective, but we do not have this type of framing in New England so I have no first hand experience to know how often anchor beam barns have spreading issues in the center aisle. if they don't it must be because the side aisles act as buttresses rather than those beautiful, huge anchor beams with huge through tenons and wedges actually do much! Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21734

11/11/09 03:15 AM Re: 6 basic assemblies

[Re: Housewright]

#21734

11/11/09 03:15 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Quickly, before I fall face first onto my key board... in the geometric workshop we built a small Dutch frame with H-bents. They were about 4' apart, I never checked them. So in a Dutch frame the anchor beams, as we called them were close together, and in the Maine barn with the dropped tie they are space at a much greater distance. This applies far more force on them than the closer spaced Dutch house frames allowing the bow in the plate. We discussed this in the workshop as well, I think it was during a slide show which Jack presented in the evening.

It was hard for me not to call the anchor beams ties.

I saw a similar close spaced H-bent house locally here in Lubec which was taken down, it was reported to have been built be a Scottish fellow in his late teens, very Dutch if you ask me.

Tim

|

|

|

Re: 6 basic assemblies

[Re: TIMBEAL]

#21737

11/11/09 11:36 AM Re: 6 basic assemblies

[Re: TIMBEAL]

#21737

11/11/09 11:36 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

As I was thinking more about it, the bent spacing was closer to 3'.

Tim

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21739

11/11/09 10:57 PM Re: 6 basic assemblies

[Re: Housewright]

#21739

11/11/09 10:57 PM

|

Joined: Apr 2009

Posts: 235

Thane O'Dell

Member

|

Member

Joined: Apr 2009

Posts: 235 |

I'm confused now. I thought it was the English barn which used the "Dropped Tie" H-frame. I have only seen pictures of the Dutch Anchor beam. Is this what is refered to as the H-frame?

Life is short so put your heart into something that will last a long time.

|

|

|

Re: 6 basic assemblies

[Re: Thane O'Dell]

#21740

11/12/09 01:44 AM Re: 6 basic assemblies

[Re: Thane O'Dell]

#21740

11/12/09 01:44 AM

|

Joined: Feb 2006

Posts: 332

Housewright

OP

OP

Member

|

OP

Member

Joined: Feb 2006

Posts: 332 |

Hi Thane and Tim; Ethnicity of building types is a very tricky business! "English" barns use normal assembly, read this about anchor beams: http://www.dutchbarns.org/dbpsnewssp93pt2.htmJim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: 6 basic assemblies

[Re: Housewright]

#21741

11/12/09 03:04 AM Re: 6 basic assemblies

[Re: Housewright]

#21741

11/12/09 03:04 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Could it be said that the anchor beams in barns are internal members, where as dropped ties extend from one exterior wall the other? They are similar but at the same time different. While in Dutch house construction you will see " anchor beams" acting as dropped ties?

Tim

|

|

|

|

|