Best practices for wall girt joints?

#22195

01/09/10 01:47 AM Best practices for wall girt joints?

#22195

01/09/10 01:47 AM

|

Joined: Nov 2009

Posts: 80

Kevin Rose

OP

OP

Member

|

OP

Member

Joined: Nov 2009

Posts: 80 |

Hi all,

I'm currently cutting the frame for a 20 x 30 equipment shed. It will be sided with 1 x 8 vertical board and batten. I'm looking at various alternatives for attaching the horizontal 3 x 5 wall girts (spaced at 3 or 4-foot intervals between the base of the frame and the tie beams/plates).

Any thoughts on the best way to join the girts with the posts? Butt-joined after the frame is up? Or, should I be cutting some half-laps into the posts/girts? Or, perhaps a partial stub tenon? (although, due to the positioning of the frame members, I'm not thrilled about putting a girt mortise a couple inches below and in line with a brace mortise)

Thanks in advance for any suggestions!

~Kevin Rose

Northern Vermont

|

|

|

Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22197

01/09/10 02:46 AM Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22197

01/09/10 02:46 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Post length?

You could share a mortice with the brace and girt, otherwise I try to keep them 6" away. I use 3" long tenons and 1, 3/4" pins on the ends of girts. I don't use a lot of half laps, I find a simple mortice is just as or quicker than lap joints. If the lap goes all the way across the member than you can saw and chop it out, thats quick and efficient.

Can you install the girts as it goes together or do they need to be installed after the post are up?

Tim

|

|

|

Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22198

01/09/10 02:51 AM Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22198

01/09/10 02:51 AM

|

Joined: Jan 2008

Posts: 918

bmike

Member

|

Member

Joined: Jan 2008

Posts: 918 |

Kevin - I did something similar on a barn I hand cut and raised a few years ago. I did 3/4" housings and then spikes.  Put these all in after the frame was raised. Tapped them in from the outside. Spiked em - but you could also panel screw them.

|

|

|

Re: Best practices for wall girt joints?

[Re: bmike]

#22202

01/09/10 11:00 AM Re: Best practices for wall girt joints?

[Re: bmike]

#22202

01/09/10 11:00 AM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

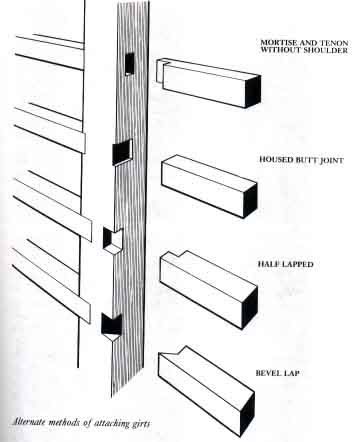

Here are some methods to attach girts:

Whatever you do, have fun doing it!

|

|

|

Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22203

01/09/10 02:31 PM Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22203

01/09/10 02:31 PM

|

Joined: Nov 2009

Posts: 80

Kevin Rose

OP

OP

Member

|

OP

Member

Joined: Nov 2009

Posts: 80 |

The posts are 10'. Can you install the girts as it goes together or do they need to be installed after the post are up? My inclination is to cut mortises for the bottom girts and install them as the frame goes together, then cut 1 1/2" half-laps for the girts that fall just below the brace mortises to preserve the integrity of the wood directly below the brace. The mid-level girts can go in after the frame is up. The shed will be set on piers with a gravel floor, therefore no sills. The bottom wall girts will be just a couple inches up from the base of the posts.

~Kevin Rose

Northern Vermont

|

|

|

Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22208

01/10/10 12:18 PM Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22208

01/10/10 12:18 PM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

When demands of assembly won't allow a nailer to be tenoned on both ends, and go up with its posts, I typically still tenon one end and Bevel Lap the other. (as above though typ with a shallow housing) Prefer it because it removes less section but still cogs the nailer into position nicely and takes fasteners well.

As an aside, I'd maybe reconsider the sills, redundancy is a wonderful thing, and a building with sills deals with a little movement in its foundation (be it stone or piers) far better than one without.

|

|

|

Re: Best practices for wall girt joints?

[Re: Will Truax]

#22209

01/10/10 04:22 PM Re: Best practices for wall girt joints?

[Re: Will Truax]

#22209

01/10/10 04:22 PM

|

Joined: Nov 2009

Posts: 80

Kevin Rose

OP

OP

Member

|

OP

Member

Joined: Nov 2009

Posts: 80 |

Will,

I hear your point about the sills. The building originally was conceived as a less substantial pole barn (for storing a tractor and implements) that evolved to a timber framed version, yet it still retains design elements from the more basic pole barn. Time will tell. Thanks for your feedback. I'm still very much a rookie apprentice at timber frame construction and appreciate any and all thoughts.

~Kevin Rose

Northern Vermont

|

|

|

Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22215

01/10/10 11:20 PM Re: Best practices for wall girt joints?

[Re: Kevin Rose]

#22215

01/10/10 11:20 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Will and Kevin, I have a smallish barn with no sills. The lay of the ground made the typical foundation cost more than I was willing to put into it. I roughed in some window cutouts from a sip panel house job and rolled cement filled tires onto them. The post went on top of the cement tires, with connecting girts about 1 foot up. It has only been 6 years so no real test of time and moving the building onto a better foundation is blowing in the wind. It is in a wet area with frost issues, still have seen no problems, yet. I agree it is not the best solution, we must do what we must.

I like the mortice and tenon and bevel lap on the other end, it hadn't crossed my mind. Ruts are sticky things at times.

Tim

|

|

|

Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22219

01/12/10 08:23 PM Re: Best practices for wall girt joints?

[Re: TIMBEAL]

#22219

01/12/10 08:23 PM

|

Joined: Feb 2006

Posts: 332

Housewright

Member

|

Member

Joined: Feb 2006

Posts: 332 |

Hi Kevin;

Your drawing is nice. As shown, you are talking about building with "inturrpted sills". The bottom nailers will act to resist minor horizontal movement of the piers, thus should be mortised and pinned.

Inturrupted sills make the raising harder than sills under the posts.

I would not worry about mortising the nailers near the braces. Historically, nailers in the walls are tenoned with approximately two inch long tenons like the top nailer in the drawing Jim Rogers provided and are rarely pinned.

Stay warm;

Jim

The closer you look the more you see.

"Heavy timber framing is not a lost art" Fred Hodgson, 1909

|

|

|

Re: Best practices for wall girt joints?

[Re: Housewright]

#22220

01/13/10 01:24 AM Re: Best practices for wall girt joints?

[Re: Housewright]

#22220

01/13/10 01:24 AM

|

Joined: Nov 2009

Posts: 80

Kevin Rose

OP

OP

Member

|

OP

Member

Joined: Nov 2009

Posts: 80 |

Jim,

Thanks for the feedback. Using the suggestions given, I'm now cutting for a pegged base of the frame. Yes, as you point out, it will be interesting to see how it all fits come raising day.

Below zero and falling . . .

Best,

Kevin

~Kevin Rose

Northern Vermont

|

|

|

|

|