Hi All,

Sorry about the new username, this is Don P. I apparently broke off my key in the lock awhile ago. Anyway...

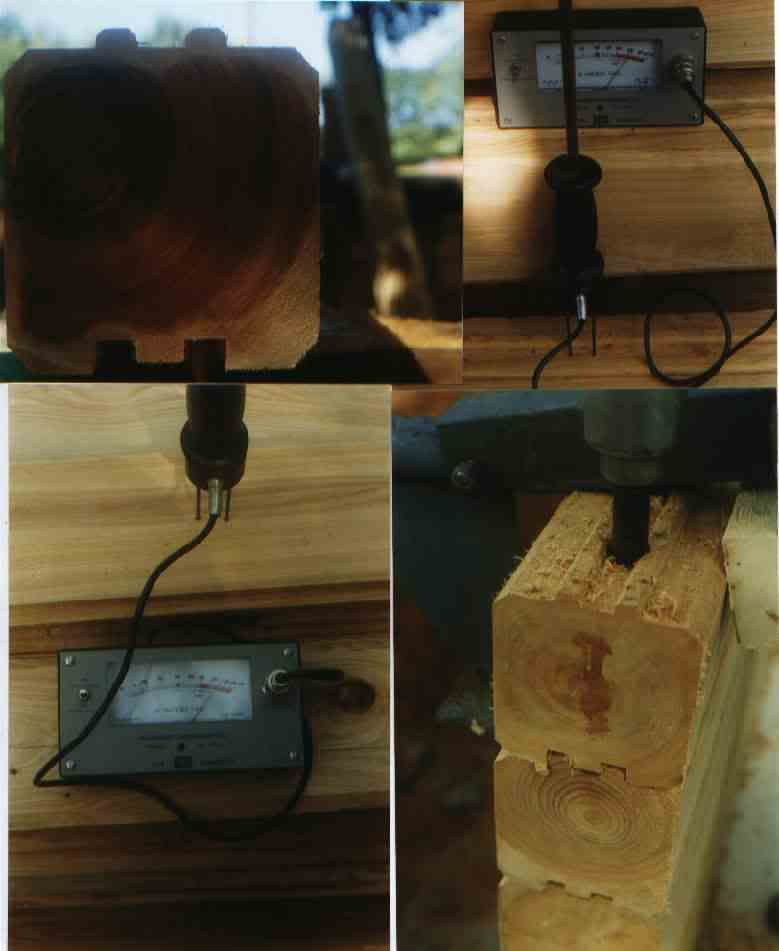

I use an older Delmhorst pin type meter with 3" insulated pins on their largest slide hammer. These meters are basically measuring resistance between the pins, in billionths of an ohm from what I understand, and convert that to a moisture content. an insulated pin reads only at the tips, so as I drive them in I'm reading the mc at the depth the pins are at. As I drive in I'm reading the "moisture gradient" from shell to core.

A high gradient is telling me that the shell is drying and shrinking around a still green and swollen core, great checking potential. A uniform reading tells me the wood is probably approaching emc... which is not a fixed moisture content anywhere. It averages about 12% in an outdoor (unheated) under shelter location here, in the VA Blue Ridge.

Gabel is pretty much right on in his comments, free moisture is the moisture within the cell lumen, bound moisture is the moisture that is chemically wrapped up with the cellulose within the cell wall itself. The point where the free moisture has left the cell cavity but has not yet begun to leave the cell wall is called the "fiber saturation point". As the bound moisture leaves the spaces within and between the cell wall fibers shrinkage begins, mechanical properties change.

A couple of interesting things happen right there, fungi need free water, as the wood dries below FSP fungi lose interest. FSP is a cell by cell point not an entire stick of wood point, remember the gradient above, the shell can be well below the FSP while the core is well above it. Drying commodity lumber down below the FSP is one way of making sure it won't decay while dead piled in a lumberyard... if they store it properly. Nowhere in the US is 19% emc though, the wood still has drying and shrinking to do from that point down to EMC. As the fibers dry they become tougher and stronger, carpenter ants cannot chew through them easily, they go looking for saturated wood.

The moisture content of a living tree does not drop in winter and in fact is sometimes higher in hardwoods where the leaves are not there to cause transpirational losses. Evergreens are evergreen because they are still growing and photosynthesizing through the winter... whenever the temperature allows the sap to flow. Winter cutting does give the wood the opportunity to dry with low moisture gradient through a period when fungi are halted by the cold, hopefully by the following spring the wood is below FSP and you can stay bright and fungi free, so there is good reason to winter cut but it isn't because sap goes down, it doesn't. Cells that embolize die, a tree cannot re-establish a broken water column.

This is a shot of my meter in some supposedly 17% cypress logs that were sold by a crook.

The top left part of the pic shows a dry shell... below fiber saturation point and a wet core, above fsp. When you can see the moisture you are seeing the free water in the cell lumen. When it looks dry you can say that it is below FSP for that species, that is all you can say at that point, but that is no small amount of knowledge right there.

If you know the temperature and relative humidity you can determine the equilibrium moisture content. The thermometer/hygrometer is giving that part of the equation here. If you look up the emc you'll see the meter is pretty much agreeing with those conditions. It's always a moving target, the temp and rh would have been a bit different a few hours before that and were surely a little different a few hours later so the emc will be within a % or so of that reading.

Timbeal had the most accurate suggestion, meters are ok but weight is the most accurate way to determine moisture content.