|

Re: ??s about joist height and brace placement

#25713

02/28/11 11:23 PM Re: ??s about joist height and brace placement

#25713

02/28/11 11:23 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Dan, #3, I don't feel right about. It is tension joinery and If you are looking to gain more room on the second floor the struts will protrude into the space. They may appear like they are doing something but is it worth it? Boost the size of the post, #1.

If the straw bale wall strengths the wall, it most likely won't help with the canted knee wall, in my view.

|

|

|

Re: ??s about joist height and brace placement

#25714

02/28/11 11:52 PM Re: ??s about joist height and brace placement

#25714

02/28/11 11:52 PM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

If you have to use struts, don't use straight mortise and tenons. You could use a 'suicide' tenon which is a tenon inserted into a mortise that is wider at the bottom and expanded with wedges driven into kerfs in it so that it can never come out again. This is a joint I am familiar with in furniture, but haven't come across it in framing. You have a flared mortise, as described, and a tenon with maybe 2 saw kerfs cut into it. When this joint is put together, you place a wedge in each kerf and then drive the strut home. The wedges expand the tenon inside the mortise, and it can't come back out. This joint resists tension, which is its function in furniture joinery. Or a lap dovetail could be used to resist tension. Or, like Tim says, you could just not use struts as they would interfere with interior space. Another solution is that you could build a truss with a profile kind of like this, which is sort of like an upper cruck, or a German Liegender Stuhl, depending on whether you use straight or curved supports...  This is I imagine a great departure from Jack's design.. But a higher knee wall is possible, it just may require rethinking the roof structure. note, this drawing is just a very quick sketch, there is nothing technical about it. I don't imagine that strawbales would do anything for you in resisting thrust. I don't know much about them, but imagine that any structural properties would be along the lines of bearing vertical loads

Last edited by D L Bahler; 02/28/11 11:55 PM.

|

|

|

Re: ??s about joist height and brace placement

#25716

03/01/11 12:27 AM Re: ??s about joist height and brace placement

#25716

03/01/11 12:27 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

It is already a small building, therefore the conservation of space would be on my list of things to keep in mind. Now, there is the issue of the short cantilevered joist ending in open space, unused space, so it may not be important.

I must just be a simpleton. Let's see, 7 more pieces, that is 14 more joints, times the 3 bents, that is 42 more joints. Or up size the post?

Not that I am knocking DL's sketch, I think it is a reasonable idea, and on a larger building it would be very reasonable. But the topic at hand is only 14' wide.

|

|

|

Re: ??s about joist height and brace placement

#25717

03/01/11 12:44 AM Re: ??s about joist height and brace placement

#25717

03/01/11 12:44 AM

|

Joined: Jun 2010

Posts: 49

danfink

OP

OP

Member

|

OP

Member

Joined: Jun 2010

Posts: 49 |

Thanks DL. I like the look of that. Something like that certainly could work.

I'm with TIMBEAL on this though, as I'm trying to keep this simple. Sizing up the post, or simply lowering the kneewall are fine options. I wonder with oak and hemlock posts (could all be calculated with hemlocks numbers) how high a kneewall I could get with 8x8s. I'll see if I can run those numbers looking thru these posts and my many books on hand.

|

|

|

Re: ??s about joist height and brace placement

[Re: timberwrestler]

#25732

03/01/11 11:40 PM Re: ??s about joist height and brace placement

[Re: timberwrestler]

#25732

03/01/11 11:40 PM

|

Joined: Jun 2010

Posts: 49

danfink

OP

OP

Member

|

OP

Member

Joined: Jun 2010

Posts: 49 |

Another consideration, that I can't remember whether Jack addresses, is that you'll need some kind of girt or nailer to at the level of the joists to catch the end of your flooring (assuming there is a loft space). That adds even more joinery at the post/TB location. There are few ways to improve that situation. timberwrestler, what are the ways you're referring to that could improve that situation?

|

|

|

Re: ??s about joist height and brace placement

#25748

03/02/11 03:01 PM Re: ??s about joist height and brace placement

#25748

03/02/11 03:01 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

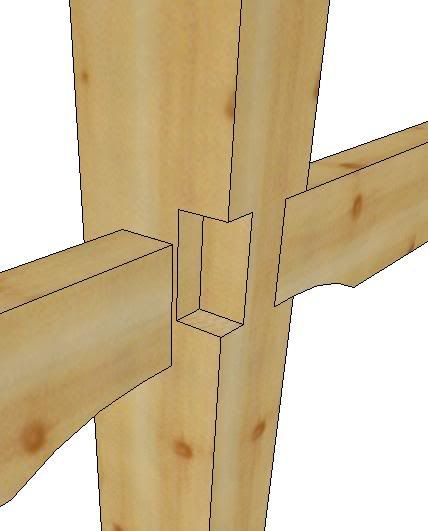

One way to attach a floor joist at the wall to a post and not create a big joinery problem is to make the floor joist a "slide-in" joist. That is you raise the frame and afterwards you slide in the joist from the outside before the siding is attached. This joist can be somewhat smaller then the joist in the middle as it will not hold up as much as the others. It will be somewhat supported by the siding being nailed to it. To make the joint not show (from the inside), a simple notch can be cut on the side of the post, large enough to hold the load and it could look like this:

Last edited by Jim Rogers; 03/02/11 03:03 PM. Reason: corrections

Whatever you do, have fun doing it!

|

|

|

Re: ??s about joist height and brace placement

#25751

03/02/11 07:05 PM Re: ??s about joist height and brace placement

#25751

03/02/11 07:05 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

Dan,

I've done what Jim mentions, with some structural screws thrown in there. If the enclosure system allows it, I've put strapping on the outside of the post that catches the flooring. With a conventionally framed wall around the frame, I've put blocking at that level. That nailer is not really taking that much weight (depending on the joist locations), it's really just to keep the ends of the flooring from flapping around.

On a separate note, I'm a big fan of Tim's idea of putting the tie beams at different heights, and using soffit tenons on one side.

Brad

|

|

|

Re: ??s about joist height and brace placement

[Re: Will B]

#25763

03/03/11 02:50 PM Re: ??s about joist height and brace placement

[Re: Will B]

#25763

03/03/11 02:50 PM

|

Joined: Jun 2010

Posts: 49

danfink

OP

OP

Member

|

OP

Member

Joined: Jun 2010

Posts: 49 |

Hey Will,

Could you please point me to a source(s) that can 1)explain/walk me thru the type of calculations you did here for my post size in regards to height, load, and removal of wood after joinery, and 2)list the various values for different species of wood. I want to qualify my feeling that Oak and Hemlock will work structurally with a taller kneewall, especially if Oak will be used for the posts in the middle bent. In the meantime I'll see what I can find.

Dan

|

|

|

Re: ??s about joist height and brace placement

#25764

03/03/11 03:13 PM Re: ??s about joist height and brace placement

#25764

03/03/11 03:13 PM

|

Joined: Jan 2008

Posts: 918

bmike

Member

|

Member

Joined: Jan 2008

Posts: 918 |

|

|

|

Re: ??s about joist height and brace placement

#25779

03/04/11 03:26 PM Re: ??s about joist height and brace placement

#25779

03/04/11 03:26 PM

|

Joined: Oct 2002

Posts: 209

Will B

Member

|

Member

Joined: Oct 2002

Posts: 209 |

Dan,

Not being an enginer, I am reluctant about giving out any definitive engineering advice over the web such as an actual calculation for someone else's project, especially without seeing all of the conditions in the design. I advise you consult an engineer or the Timber Frame Engineering Council. That said, if you want to learn to figure this yourself, you could consult the books that Mike recommends, especially the tension joinery articles in the 1st volume. Design values for the various woods are also there, in the NELMA grading manual and the National Design Specification Supplement published by the AFPA. Calculating the new centroid based on the removed material in the post can get a bit complicated, but I would recommend some of the books in the Parker/Ambrose simplified structural design for builders series. We also cover much of this material, and the calculation I used, in our Timber Frame Design and Joinery Decisions course at Heartwood. I'm reluctant to just throw this calculation out there because there are many underlying assumptions and data that need to be considered, and the calculation needs to be done with a background understanding of basic engineering, such as where to find design values for the wood. In our design course we have a week to build up to this sort of calculation, but it's too much to do here.

|

|

|

|

|