|

What to look for in a slick? Which one to get?

#25588

02/22/11 04:54 PM What to look for in a slick? Which one to get?

#25588

02/22/11 04:54 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

Having nibbled with chisels for a little while, I realize a need for a larger tool more appropriate for larger joinery jobs. So, I am looking to obtain a slick, which will be used mainly for grand scale furniture projects and some light framing jobs. It is however possible that I might find some use for it in more than just one or two log home building projects as well. The typical materials to be worked will be scots pine and spruce, which are abundant here in Finland.

The two tools available from my supplier are the 60mm and 85mm slicks by Robert Sorby. I gather that these are probably quality tools, does anyone have more perspective on this? Ergonomy is a priority to me, what should I be looking for in a slick in that respect?

Another question is the breadth of the cutting edge. With 60mm and 85mm slicks available, how should I decide upon the right size? How does the width of the tool relate to the size of the joints used? Basically, if I end up ordering either one of the Sorbys, I will have to decide which one is optimal for me.

|

|

|

Re: What to look for in a slick? Which one to get?

#25598

02/23/11 01:51 AM Re: What to look for in a slick? Which one to get?

#25598

02/23/11 01:51 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

In timber framing on a large scale, I find the slick indispensable. The only time I don't use it is if it does not fit in the pocket or housing. How about a 2" chisel just sharpened a little different. Give the edge a slight radius to the cutting edge, and on the bottom, not the bevel side, hone or reshape so it is not flat but has a belly in it, just like a large slick should have.

I am also starting to discover I like a longer handle. The slick I use has a nice but shorter handle, I am thinking of adding a foot or so to a new handle, pushing it to 3'. What lead me to this is the scarf slick I have been using it has a wonderful long handle on it, it is like a great big gouge, it really hogs the wood off. I'm not sure what makes the longer handle nicer, could be the mechanics of it, more body behind it.

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: TIMBEAL]

#25602

02/23/11 09:45 AM Re: What to look for in a slick? Which one to get?

[Re: TIMBEAL]

#25602

02/23/11 09:45 AM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

The thought of getting a slick for myself actually arose from the fact that I found myself supporting my chisels against my waist or shoulder while paring some of the joints. Now especially when working with the chisel in a vertical position, I find it difficult to get my posture just right, which made me think I could benefit from using a longer tool instead.

Rounding the back never crossed my mind, but I can see how this helps in the paring process. I will probably try that out with my regular paring chisel, it really seems like a very good idea, especially in terms of getting a smoother finish with less effort. And if I figure this out correctly, having the back ever so slightly curved, also results in the cutting edge coming out with a slight radius when the bevel is ground flat.

But I won't be giving up the idea of obtaining a slick just yet. I'm in no hurry, though. So I have plenty of time to ponder any options that might come by.

|

|

|

Re: What to look for in a slick? Which one to get?

#25603

02/23/11 11:15 AM Re: What to look for in a slick? Which one to get?

#25603

02/23/11 11:15 AM

|

Joined: Aug 2009

Posts: 306

Cecile en Don Wa

Member

|

Member

Joined: Aug 2009

Posts: 306 |

Hello,

Putting a radius on the cutting edge will complicate cleaning out the corners at the bottom of a mortise where everything should meet at right angles. It will make paring easier though. I wonder why you would round the back instead of the bevel if your intention is to alter the radius of the cutting edge. It seems, along with reducing friction that it would make sharpening more difficult.

You do have more (and better) options than the Sorby one, that is unless you are trying to avoid added transportation. Dieter Schmid, in Berlin or Rudolph Dick, in Metten have very nice slicks. Their Japanese ones - which have hollow backs - might even be better suited to the kind of work you describe you are doing. If you were a Frenchman or German you would probably choose for a bisaiguë or demi-bisaiguë.

Greetings,

Don Wagstaff

|

|

|

Re: What to look for in a slick? Which one to get?

#25607

02/23/11 12:15 PM Re: What to look for in a slick? Which one to get?

#25607

02/23/11 12:15 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

Don, sharpening a belly on a slick or chisel is not difficult, just apply a little more pressure on the edges when it is laid flat on the stone. This of course will rub some the wrong way and go against their grain, such is the way when working with wood. It is not much of a belly, with a straight edge applied to the back of the slick you can see daylight at the ends, I dare not guess at the amount, but I can see it is not flat.

I try to think of a slick as being sharpened in a similar way as a single bevel hewing axe. The same effect, in the slick and the mentioned 2" chisel, is of course not as pronounced. It leaves the tool with a leading edge which is able to skew across fibers in effect easing the process. It need not be so rounded that it effects how it cuts in the bottom of the mortice.

Hand plane blades are sharpened this way as well. If one was on the ball, which I am not, they could have a number of them for different jobs and needs. One blade does not fit all jobs.

|

|

|

Re: What to look for in a slick? Which one to get?

#25620

02/23/11 10:06 PM Re: What to look for in a slick? Which one to get?

#25620

02/23/11 10:06 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

I love the slick. I really did not start to use one for awhile and then was nudged to pick up the tool. I like to use it on mortise sides. If you mortise needs a little more width, you are only tiring your self out if you aren't using the slick. Big cutting edge and mass. Thrust it down the mortise and your done.

I put a radius on my straight edge Barr slick. I also had the smithy straighten up the whole tool a little bit so dropping plumb was easier to reference by eye. For the radius, I spent some time with a file. To sharpen, I like to take the stone to it. Slipstones work well.

|

|

|

Re: What to look for in a slick? Which one to get?

#25621

02/23/11 11:58 PM Re: What to look for in a slick? Which one to get?

#25621

02/23/11 11:58 PM

|

Joined: Feb 2006

Posts: 718

Dave Shepard

Member

|

Member

Joined: Feb 2006

Posts: 718 |

mo, were you able to put a file to the Barr chisel? I often take the soft steel off of my framing chisels with a file, so that I only have to work on the hard steel with the coarse diamond stone. The file won't touch the hardened steel on my chisels or slicks. I mostly use my slicks for working on large surfaces, like parts of a scarf joint. Sometimes for paring off tenons. Large tenons, like those on an anchorbeam, I use the broadaxe, the same as when they were built originally.

Member, Timber Framers Guild

|

|

|

Re: What to look for in a slick? Which one to get?

#25631

02/24/11 12:52 PM Re: What to look for in a slick? Which one to get?

#25631

02/24/11 12:52 PM

|

Joined: Nov 2006

Posts: 850

mo

Member

|

Member

Joined: Nov 2006

Posts: 850 |

Hey Dave, I remember trying many files that just glided across without doing a thing. I think that finally did it might have had some bling bling on it. Didn't get a true radius. I was occupied for a many hours just to knock down the corners from right angles to slight arcs, it looks like a good jack plane iron now, as far as top view.

|

|

|

Re: What to look for in a slick? Which one to get?

#25633

02/24/11 03:36 PM Re: What to look for in a slick? Which one to get?

#25633

02/24/11 03:36 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

Rounding the back of a paring chisel or slick ever so slightly would have the effect of making it a little less prone to dig in at the corners. In plane blades, which are mostly used bevel down, it is the bevel side which is cambered slightly. Don, I assume that by demi-bisaigue you mean something like this mortising ax: http://www.mehr-als-werkzeug.de/product/708364/D-Mortise-Axe/detail.jsf . The one by Stubai appears to have pretty similar proportions. Does someone here have first-hand experience on using one of these, or a bisaigue for that matter? Mo, my exact thoughts about the mortises. And the broader the cutting edge gets, the more force you need to use to push it through. Mortises aren't my primary concern, though. Most of the work can be done with a chisel and a mallet. But trimming those tenons to fit snugly takes some effort with tools that are more than undersized. My broadest chisels are unfortunately also the shortest.

|

|

|

Re: What to look for in a slick? Which one to get?

#25638

02/24/11 10:13 PM Re: What to look for in a slick? Which one to get?

#25638

02/24/11 10:13 PM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

TWhat you have pictured there Markus, is not the demi besaigue, but a similar tool Demi Besaigue is the French name for a German tool, which is known as a Stichaxt or Stossaxt. Sometimes this is in English called a push axe. It occupies a gray area somewhere between the axe and the chisel. It is often referred to as the 'German Slick' and the Germans refer to the slick as being an American or British thing. http://www.traditionalwoodworker.com/1-3...tinfo/598-4500/There is one you can get in the US, made by Ochsenkopf I have one, and I love it. It is useful for a number of things, and is perhaps more versatile than the slick. Traditionally it is used in Germany as an all purpose cleanup tool. Used to clean mortises and other such joints like a slick, but also used to smooth timber faces -instead of an adze or a variety of hand planes- which it works rather well at. The French Besaigue is a development of the German Stichaxt (which itself is a variation of the older Kreuzaxt, which in one form is more or less what you have linked to there.) in which a heavy duty mortising chisel has been added at the other end. both tools are essentially used the same way. To use the stichaxt, you need to have the timber fairly low to the ground, so that you stand mostly above it. You will see in old pictures from Germany and France that the timbers are always low to the ground, never worked high up on horses. This is necessary because you use your body weight to work the stichaxt. You work in a kneeling position with one hand on the tools short handle and the other a few inches down on the body, and with a rocking motion push the tool across the wood. It can make very fast work of removing relatively large quantities of wood. The Kreuzaxt from which it was developed is essentially a twibil, and was originally used to rough out mortises that had first been bored out. eventually they just decided to take the wooden handle off of it. It is not clear what all it was used ofr originally, but eventually it came to be used as a cleanup tool. The Besaigue may or may not have been originally French, as I understand it is generally considered to have been invented somewhere in or around Alsace, a historically German speaking region that is part of France today. It is important to note that the Germans have a specific system of tools worked out for timber framing. They are well adapted to their style of joinery, and perhaps more importantly well adapted to each other. The Stichaxt is just one of these tools. If It were an american tool, we would probably call it a chisel, but the Germans mostly used axes to do things that we would use chisels and saws for, and so they saw it as one of a series of axes used to cut a frame. hence the name Stichaxt (Axt being one word in German for axe)

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: Markus Nyman]

#25643

02/25/11 01:19 AM Re: What to look for in a slick? Which one to get?

[Re: Markus Nyman]

#25643

02/25/11 01:19 AM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

[quote=Markus Nyman]Rounding the back of a paring chisel or slick ever so slightly would have the effect of making it a little less prone to dig in at the corners. In plane blades, which are mostly used bevel down, it is the bevel side which is cambered slightly.

Yes, a good point I believe I over looked. I do not sharpen my plane blades the same as my slick. I don't know what got into me!

When it comes to mortice and tenon work, I find the axe and slick do most of the work, other than crosscutting with the saw.

DL, any specific sharpen points to the Stichaxt? As it is used in reference to an axe, is it sharpened in a similar manor?

|

|

|

Re: What to look for in a slick? Which one to get?

#25645

02/25/11 02:20 AM Re: What to look for in a slick? Which one to get?

#25645

02/25/11 02:20 AM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

The business end of the stichaxt is more or less a giant chisel. It is single beveled, and the direction of the handle determines how the tool is handed. If the handle goes off to the right, then it is right handed. The angle of the bevel is about the same as that of my framing chisel. Mine is a bit over 17 1/2 inches long, and about 5" wide at the handle. It is 1 3/4 inches in the body. The back may or may not be slightly convex, depending on who makes it. I need to make one correction to my previous post concerning how to use it. The correct posture is not simply kneeling, but rather kneeling with one knee resting on the timber being cut and the other extended out to the side. The timber needs to be at the proper height so that this is comfortable. The top of the timber might be about the height of a chair. You should always have the timber turned so that you are cutting down when using the stichaxt. You can cut horizontally, but it works better to always cut down. Here are some pics that may help clarify things for you.  First a size comparison, next to a 1 1/2" framing chisel notice the beveled sides, which help the tool to cut more efficiently.  and a closeup of the business end so you can see the bevel hope this answers your questions, Tim

|

|

|

Re: What to look for in a slick? Which one to get?

#25656

02/25/11 12:31 PM Re: What to look for in a slick? Which one to get?

#25656

02/25/11 12:31 PM

|

Joined: Aug 2009

Posts: 306

Cecile en Don Wa

Member

|

Member

Joined: Aug 2009

Posts: 306 |

Hello,

All these different variations are sure interesting but also maybe diversions. I'll be keeping my eyes open next time I go to France or Germany for a chance to get a hold of some of these different old time tools though.

I'm using the slick from that smidt up in McCall for the past 12 or so years and have always been pleased with it. Some of the things I like about it include the ergonomics of the handle, that it has swells and ridges, and mostly the flared and rounded knob at the end. It means I can get good grip and resistance and apply pressure from many positions. There is nothing wrong with the steel and tempering, though it will deflect before it chips I have noticed. I think they do go a bit overboard with grinding and polishing though.

I don't know about altering the geometry of its cutting edge. This I have never felt the need to do. But I will comment on the shape of the blade over-all. For me, the top side, that is the area behind the bevel, being overly rounded, makes it more difficult to prop up and steady during sharpening than it needs to be. It is nice that you can lay a hand over the blade for guiding and apply some pressure and not have sharp edges there, and I'm glad the smidt was thinking about this when forging the tool but it does minimize the bevel's surface contact when you lay it up to the stones.

Greetings,

Don Wagstaff

Last edited by Cecile en Don Wa; 02/25/11 12:34 PM.

|

|

|

Re: What to look for in a slick? Which one to get?

#25698

02/27/11 08:55 PM Re: What to look for in a slick? Which one to get?

#25698

02/27/11 08:55 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

Bahler, A stichaxt seems like a feasible alternative to a slick. Your detailed description is most helpful. What I will have to do is give some thought to my workflow, in order to choose for the tool best suited for my purposes.

Don, that's a good point about the rounded top side. My combination of a Tormek and a small diamond lap stone somewhat evades any issues with steadying the tool, though.

The japanese slicks seem to have straight handles. Rehandling, however still remains an option. I'm really two minds about the slightly hollowed backs. They do make flattening effortless, but yet I'm slightly suspicious about the whole thing. I realize though, that it's a feature well thought out.

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: Markus Nyman]

#25744

03/02/11 03:09 AM Re: What to look for in a slick? Which one to get?

[Re: Markus Nyman]

#25744

03/02/11 03:09 AM

|

Joined: Jul 2009

Posts: 29

Devin Smith

Member

|

Member

Joined: Jul 2009

Posts: 29 |

I have two slicks and use both pretty regularly. One is a 4" Witherby-- great steel. Its sharpened dead flat on the back and with a radius on the bevel side. I use it for fine precise shaving and flattening mostly. Its a beatiful tool, so I tend to baby it a bit. The radiused bevel can be used "upside down"-- cutting with the bevel edge down-- to nice effect. Removes wood quickly, if need be, and also can be used to create a nice scalloped texture-- almost like a adzed surface. My other slick-- a 3" no-name "cast steel" is much better for gross wood removal, and also the one I'm a bit more willing to beat up on a bit. It is "rockered" on the backside as Tim is (I think) describing, which lets you pull your cut out when it tries to dig in too much (something that tends to happen when you remove a lot of wood quickly. It also gives you hand clearance for paring things with the grain in the middle of a timber. I have the bevel edge sharpened straight and square to the sides-- which also facilitates cleaning out occasional 3" wide mortises-- which I usually use for a tongue and fork joint at the peak, and in other special circumstances. I normally use a framing chisel to clean out normal 1 1/2" or 2" pockets. I've used the Barr slick some as well-- a friend owns one. Though it seems like a nice tool, I much prefer the older slicks like the ones I own. Its biggest limitation as I see it is that its way too light. So much of the slick's function derives from weight and momentum. You sharpen it up to a razor edge and focus on pushing its mass in a straight line. Inertia takes care of the rest. The Barr tool is so light that it makes you work much harder and the tool moves around a lot more. Its shape is also awkward in my opinion-- I think I would like it more if it were more straight rather than having the blade curve upward so much. A nice slick is a pleasure to use.

|

|

|

Re: What to look for in a slick? Which one to get?

#25855

03/09/11 10:36 PM Re: What to look for in a slick? Which one to get?

#25855

03/09/11 10:36 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

Thanks everyone for your advice. Not only did I find out more about slicks, but learnt a valuable lesson on tuning my chisels to my needs. I ended up grinding a radius on the bevel side of my two inch one. I think it still needs a little more curvature; I'll work on that.

After some more frustration with my little, good-for-next-to-nothing tools, I ended up ordering the mortising ax I showed you earlier on. I quite like the wooden handle, and the fact that I can always turn it into a froe when my nerves fail me for good. I'll keep looking for that real broad mother of a slick. Knowing myself, I will eventually obtain every tool known to man as far as the state of my finances admit. However considering my mortgage, that day won't be dawning anytime soon.

|

|

|

Re: What to look for in a slick? Which one to get?

#26067

03/27/11 02:31 PM Re: What to look for in a slick? Which one to get?

#26067

03/27/11 02:31 PM

|

Joined: Jun 2002

Posts: 63

Pete Ladd

Member

|

Member

Joined: Jun 2002

Posts: 63 |

I thinkDevin has very good points. To my mind a "slick" is not a 2" chisel but a much wider and heavier tool.

A heavy tool carries momentum that helps to shave and pare down the inside face of a mortise, or across the flat of a scarf table. (In fact the etymology of the word comes from "slice.") The mass also damps and steadies the motion. That leaves one's energy available for precise guidance, rather than providing brute force, and the long handle allows very good control of the angle. A razor edge is mandatory.

I use a lightly radiused edge, and the slick functions as a giant plane. Lovely tool - when I am handling it I feel I'm channeling the spirit of medieval craftspeople.

Pete

Last edited by Pete Ladd; 03/27/11 02:33 PM. Reason: oops

|

|

|

Re: What to look for in a slick? Which one to get?

#26071

03/27/11 05:15 PM Re: What to look for in a slick? Which one to get?

#26071

03/27/11 05:15 PM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

The difference in the continental 'slicks' is that you are relying on a different weight source for the momentum of the cut. With an English-style slick, you have a massive tool whose own mass is enough to keep it going. With the continental variety you are positioning your body above the cut and relying on your own mass, which is significantly greater than the tools, to make the cut.

The big difference I see is that the tools are adapted to different ways of working. German and French carpenters worked with their timbers on or very close to the ground, and so they can very easily put their own mass behind a cut. English and American carpenters liked to put their timbers up much higher, where it is impractical to try and put your weight behind a cut, and so instead they make very large tools with a great deal of mass of their own.

If you are going to be working with timbers at or above waste height, then you had better use a slick, if you will be working with timbers lower than this than you should use you body weight to your advantage as much as possibly, in which case the continental varieties may prove more effective.

It should also be noted that the English were typically working with much bigger things than the Germans were, for example joint sizes. German mortises are a lot smaller, and a smaller tool is needed. English mortises are huge, so a huge tool is nice.

If you are going to be doing things the way most American TF'ers do it, then you should use the familiar style of slick -it is adapted to this way of working. If you however opt to work with low timbers, the Stichaxt is a great way to go

DLB

|

|

|

Re: What to look for in a slick? Which one to get?

#26085

03/29/11 02:45 AM Re: What to look for in a slick? Which one to get?

#26085

03/29/11 02:45 AM

|

Joined: Jun 2002

Posts: 63

Pete Ladd

Member

|

Member

Joined: Jun 2002

Posts: 63 |

DLB, Interesting points.

I suppose the next question is "why" do timber working heights differ? Because of the tools? (A chicken-and-egg puzzle?)

Pete

|

|

|

Re: What to look for in a slick? Which one to get?

#26086

03/29/11 03:28 AM Re: What to look for in a slick? Which one to get?

#26086

03/29/11 03:28 AM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

Who knows?

I would guess, this is just a guess here, that there are a number of factors that go into working heights, and no small part of that I imagine would be purely cultural.

I know that most craftsmen in the west tend to work on elevated benches so they can work comfortably standing up, but in Asia most craftsmen work in a squatting position, while in many cases the tools they use are more or less identical, or at least fundamentally similar.

My guess, then, is that the biggest reason originally for timber heights is cultural preferences. Somebody in England perhaps decided it would be more comfortable to work with timbers up high, while Continental carpenters continued working them down low. Then I suppose over the course of the Middle Ages the tools adapted to how they worked with the wood, as did joinery and methods.

Of course there is probably a lot more to it than this, usually things really aren't so simple but have a number of factors affecting them.

DLB

|

|

|

Re: What to look for in a slick? Which one to get?

#26095

03/29/11 06:56 PM Re: What to look for in a slick? Which one to get?

#26095

03/29/11 06:56 PM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

Will, the English and early Americans certainly used scribe technique as well, yet it seems they still brought the timbers up higher when they were cutting the joinery.

Also, the Germans were the least inclined of all to use gigantic timbers, yet they seem to have kept their timbers as low as anyone, and in many cases still do.

It seems to me that in many cases traditionally the joinery is not cut on the scribe floor, but the framework is all scribed and the timbers taken to another place to be cut, which allows for continuous scribing and cutting, i.e. efficient division of labor.

|

|

|

Re: What to look for in a slick? Which one to get?

#26099

03/29/11 11:52 PM Re: What to look for in a slick? Which one to get?

#26099

03/29/11 11:52 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I am re reading Big House, Little House, Back House, Barn, in it on page 143 there is a picture of a crew working timber, ca. 1900. The top surface of the timber appears to be just just above the knee, 20-24". That is about 10-12 inches below what I typically position my timber at. Many times I feel the 30" I work at is too high. It is good for some task, like layout, but cutting is usually more comfortable at a lower height, which I seldom take advantage of. Regardless the height, I find the slick used at any height without encumbrance, the body adjusts easily. I find no reason to not use a slick at a lower timber level, actually I find myself standing up on top of the timber some times.

|

|

|

Re: What to look for in a slick? Which one to get?

#26106

03/31/11 02:07 AM Re: What to look for in a slick? Which one to get?

#26106

03/31/11 02:07 AM

|

Joined: Jun 2002

Posts: 63

Pete Ladd

Member

|

Member

Joined: Jun 2002

Posts: 63 |

I share Timbeal's feeling that a large slick with a long handle is easy enough to use low or high - on vertical faces. Horizontal planing is easier at a high level, but I can kneel if necessary.

As to working height in general, I benefitted from a trip to Plimoth Plantation and a good conversation with a re-enactor who was ax-hewing timbers there. His working position was to have one foot on the ground, and the other foot hooked under him onto the log in a semi-kneeling/squatting manner. In effective his own weight locked him to the log and I sure it steadied his accuracy on the vertical down strokes.

I mention this because it was lower working height for the log/timber than I had been using previously when hewing. "Just above the knee" as mentioned above. Maybe that relates somehow to the joinery question.

Last edited by Pete Ladd; 03/31/11 02:08 AM. Reason: duh

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26112

04/01/11 12:11 AM Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26112

04/01/11 12:11 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

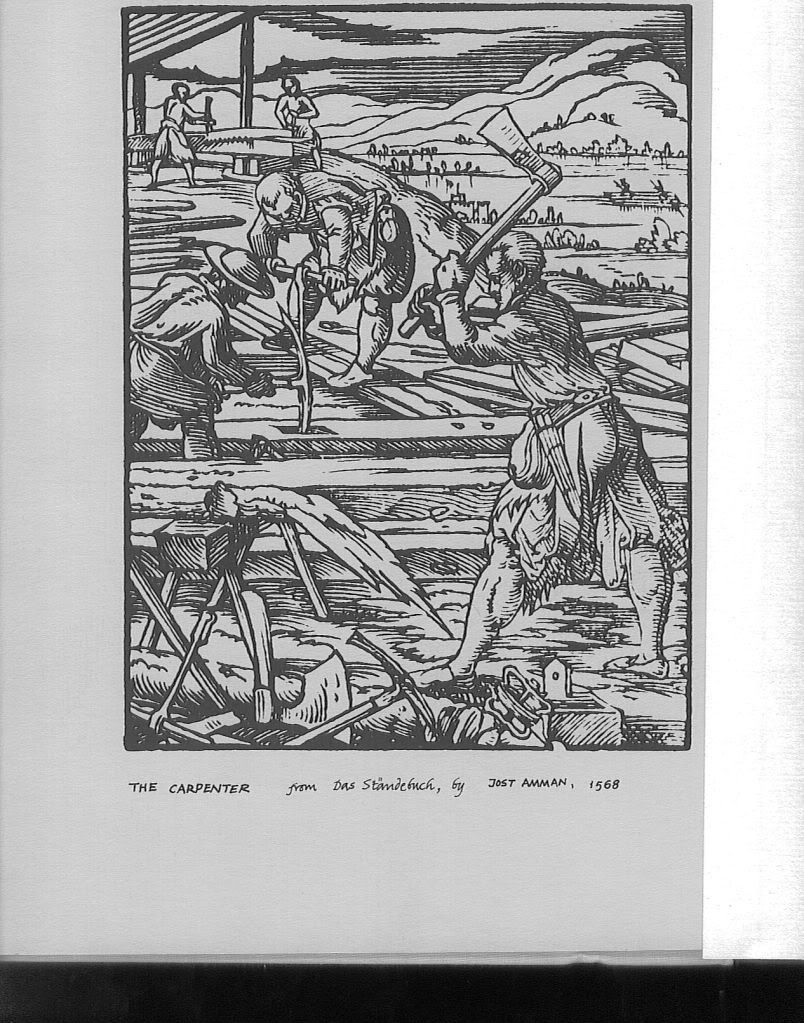

Weird – The Gremlins in this forum have to date, only been a nuisance, that and a hindrance in finding posts. But now they seem to have kicked it up a notch, and have somehow made my post to this thread go missing ??? DL – I wasn't saying that big wood and scribe were the universal driving forces, just some of the contributing factors, in the use of tooling intended to work timber low, like scribe is and the efficiency of keeping things on or near the scribe floor. I was again not suggesting that these were the only factors. I'm also well aware that the English and its colonists here in America scribed by tradition, I am surrounded by it, blessed to live on a rural road peppered with buildings built in the1760's and 70's in the building boom that erupted as long strife came to an abrupt end at the conclusion of the F&I. Houses and barns which here on the road still outnumber all those that have been built since. Scribed English tying is the rule here in Northern New England, these layout methods practiced here for a full two centuries, a mark Square rule is only now just about to reach. I've also been in many English English frames having been frame spotting in the UK more than once. I've been scribing houses, barns and bridges for near twenty years, having learned from a Brit framer many years ago now. Many of these years spent here on the ridge, in what might be described as a typical carpenters yard. I mention this to demonstrate why it is I might have some understanding as to the flow of work in a scribe yard. Most timber goes into at least two layups and stays in or near that area until the final drop it will see, and only then moves to the cutting area, posts plates and ties typically staying put because this flat level area tends to double as the assembly area. Secondary members which go into only one layup, go into a pile, waiting to be cut, as a needed something to do to keep the crew busy on rainy days under smaller covered workstations Division of labor and approach to the work in the scribe yard is not driven by hierarchy, or a desire to scribe continuously, that is just how a scribe yard works, most of the cutting is post layout. It is driven by circumstance and the weather. Its akin to swinging an ax day in day out to cut joinery. With the daily doing comes the understanding that the methods you are using are working for you because they worked for those we are following.  I've always been fond of this Ammon woodcut of a probable German carpenters yard because it shows hewing at what I see as the appropriate height, and it would seem almost backwards to many. What is seen as the logically low work is happening high, while most tasks related to the cutting of joinery are happening low.

|

|

|

Re: What to look for in a slick? Which one to get?

#26114

04/01/11 01:42 AM Re: What to look for in a slick? Which one to get?

#26114

04/01/11 01:42 AM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

Will,

Thanks for the reply

I didn't intend that all timbers got carted off the scribe floor, obviously that would be impractical.

Das Ständebuch, by Jost Amman. Interesting.

This, I can tell you, is a Swiss carpenter's setup. The reason I say that is because the name, Jost Amman, is typically Swiss. The name Jost, spelled Yost, is to this day used among the Amish in America, and spelled Jost is a fairly common name in Switzerland. The surname Amman, also, is immediately recognizable to me as the name of one Jacob Amman, from whom the Amish derive their name. This fellow, in fact, was from Zürich.

Judging from this, and from what I know from study, this would have been a typical South German/Swiss/Austrian setup of this time period. Notably missing are later developments such as the stichaxt (whose immediate predecessor, the Kreuzaxt, is seen twice)

Also notice that you don't see any saws (aside from the big crosscut) or chisels, neither of which are used much if at all in the German tradition. How many of you would be comfortable cutting your mortises without a chisel? Or even without a saw?

Also, Will, notice that these guys seem to have another thing in common with your setup, the majority of their timbers are out in the open, but in the upper left corner you can see there is a shelter of sorts.

The works of Amman are very valuable for such observations, he is said to have paid great attention to detail and accuracy, and his works have been used to gain tremendous insights into this period. Das Ständebuch in particular is an extremely valuable collection of woodcuts showing a number of period (1560's) artisans at work in excellent detail.

If you have any other such images, I would love to see them. I strive to use primary sources like these in my research as much as possible.

Also, I like and appreciate your insights, Will. I am merely trying to set up my work for an old-world traditional carpenter's setup, using the old ways and tools. So whenever I can hear from someone who has done it such as yourself, I eat it right up! Keep it coming...

My eventual goal is to do things just about like the picture you have here, with a few more modern tools here and there just for the fact that this is a business. I am the kind of guy that if there is any way I can make something instead of buying it, I will!

Sine I made some of my earlier comments, I have read some more, and think I may have to revise a bit.

I am becoming more and more convinced that the early American carpenter's also worked their timbers a lot lower than framers do now, and that our working habits are perhaps a product of the fact that we have been influenced by later developments in building. Does anyone have any evidence, such as drawing and engravings, to suggest that this may be a false conclusion?

If this is a true conclusion, then by extension my theory regarding the slick has to be discarded.

DLB

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26123

04/02/11 10:13 PM Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26123

04/02/11 10:13 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

It is so nice to see that this topic has been revived while I have been away. I find the question of tool preferences and working heights very interesting, and it really would deserve a thread of its own. With my level of ignorance, it will take someone else though, to keep up the conversation at this stage. But I certainly yearn to see and hear more about the topic.

|

|

|

|

|