|

Re: What to look for in a slick? Which one to get?

#26095

03/29/11 06:56 PM Re: What to look for in a slick? Which one to get?

#26095

03/29/11 06:56 PM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

Will, the English and early Americans certainly used scribe technique as well, yet it seems they still brought the timbers up higher when they were cutting the joinery.

Also, the Germans were the least inclined of all to use gigantic timbers, yet they seem to have kept their timbers as low as anyone, and in many cases still do.

It seems to me that in many cases traditionally the joinery is not cut on the scribe floor, but the framework is all scribed and the timbers taken to another place to be cut, which allows for continuous scribing and cutting, i.e. efficient division of labor.

|

|

|

Re: What to look for in a slick? Which one to get?

#26099

03/29/11 11:52 PM Re: What to look for in a slick? Which one to get?

#26099

03/29/11 11:52 PM

|

Joined: Dec 2007

Posts: 1,882

TIMBEAL

Member

|

Member

Joined: Dec 2007

Posts: 1,882 |

I am re reading Big House, Little House, Back House, Barn, in it on page 143 there is a picture of a crew working timber, ca. 1900. The top surface of the timber appears to be just just above the knee, 20-24". That is about 10-12 inches below what I typically position my timber at. Many times I feel the 30" I work at is too high. It is good for some task, like layout, but cutting is usually more comfortable at a lower height, which I seldom take advantage of. Regardless the height, I find the slick used at any height without encumbrance, the body adjusts easily. I find no reason to not use a slick at a lower timber level, actually I find myself standing up on top of the timber some times.

|

|

|

Re: What to look for in a slick? Which one to get?

#26106

03/31/11 02:07 AM Re: What to look for in a slick? Which one to get?

#26106

03/31/11 02:07 AM

|

Joined: Jun 2002

Posts: 63

Pete Ladd

Member

|

Member

Joined: Jun 2002

Posts: 63 |

I share Timbeal's feeling that a large slick with a long handle is easy enough to use low or high - on vertical faces. Horizontal planing is easier at a high level, but I can kneel if necessary.

As to working height in general, I benefitted from a trip to Plimoth Plantation and a good conversation with a re-enactor who was ax-hewing timbers there. His working position was to have one foot on the ground, and the other foot hooked under him onto the log in a semi-kneeling/squatting manner. In effective his own weight locked him to the log and I sure it steadied his accuracy on the vertical down strokes.

I mention this because it was lower working height for the log/timber than I had been using previously when hewing. "Just above the knee" as mentioned above. Maybe that relates somehow to the joinery question.

Last edited by Pete Ladd; 03/31/11 02:08 AM. Reason: duh

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26112

04/01/11 12:11 AM Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26112

04/01/11 12:11 AM

|

Joined: May 2002

Posts: 447

Will Truax

Member

|

Member

Joined: May 2002

Posts: 447 |

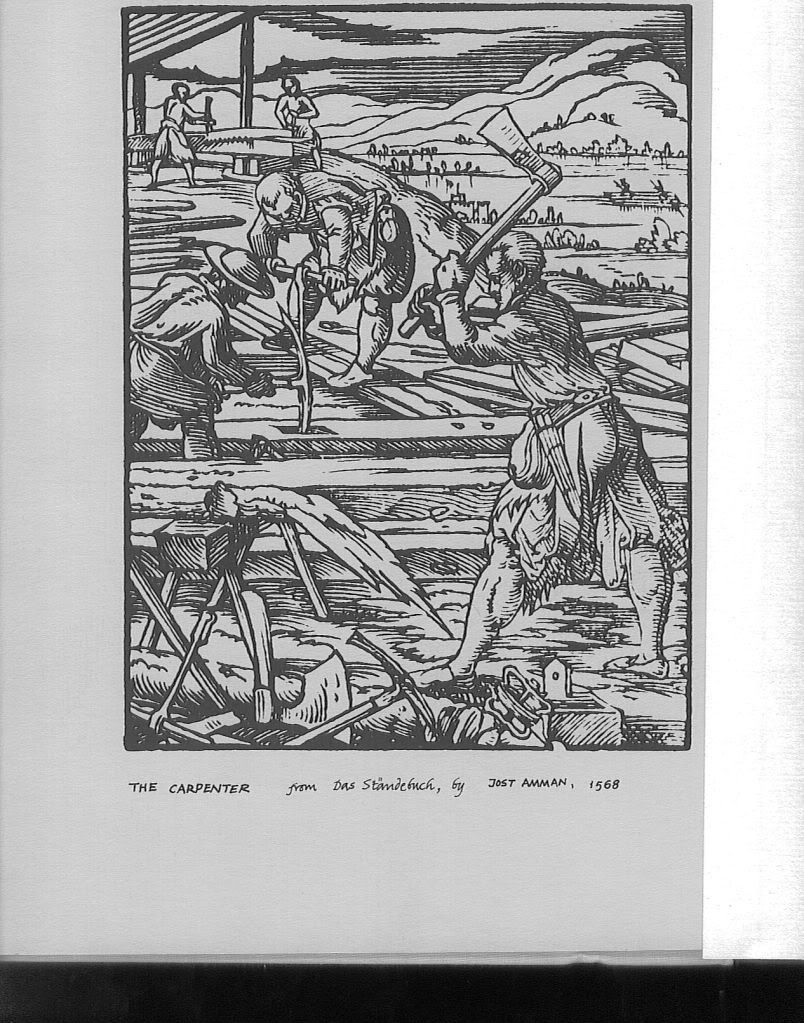

Weird – The Gremlins in this forum have to date, only been a nuisance, that and a hindrance in finding posts. But now they seem to have kicked it up a notch, and have somehow made my post to this thread go missing ??? DL – I wasn't saying that big wood and scribe were the universal driving forces, just some of the contributing factors, in the use of tooling intended to work timber low, like scribe is and the efficiency of keeping things on or near the scribe floor. I was again not suggesting that these were the only factors. I'm also well aware that the English and its colonists here in America scribed by tradition, I am surrounded by it, blessed to live on a rural road peppered with buildings built in the1760's and 70's in the building boom that erupted as long strife came to an abrupt end at the conclusion of the F&I. Houses and barns which here on the road still outnumber all those that have been built since. Scribed English tying is the rule here in Northern New England, these layout methods practiced here for a full two centuries, a mark Square rule is only now just about to reach. I've also been in many English English frames having been frame spotting in the UK more than once. I've been scribing houses, barns and bridges for near twenty years, having learned from a Brit framer many years ago now. Many of these years spent here on the ridge, in what might be described as a typical carpenters yard. I mention this to demonstrate why it is I might have some understanding as to the flow of work in a scribe yard. Most timber goes into at least two layups and stays in or near that area until the final drop it will see, and only then moves to the cutting area, posts plates and ties typically staying put because this flat level area tends to double as the assembly area. Secondary members which go into only one layup, go into a pile, waiting to be cut, as a needed something to do to keep the crew busy on rainy days under smaller covered workstations Division of labor and approach to the work in the scribe yard is not driven by hierarchy, or a desire to scribe continuously, that is just how a scribe yard works, most of the cutting is post layout. It is driven by circumstance and the weather. Its akin to swinging an ax day in day out to cut joinery. With the daily doing comes the understanding that the methods you are using are working for you because they worked for those we are following.  I've always been fond of this Ammon woodcut of a probable German carpenters yard because it shows hewing at what I see as the appropriate height, and it would seem almost backwards to many. What is seen as the logically low work is happening high, while most tasks related to the cutting of joinery are happening low.

|

|

|

Re: What to look for in a slick? Which one to get?

#26114

04/01/11 01:42 AM Re: What to look for in a slick? Which one to get?

#26114

04/01/11 01:42 AM

|

Joined: May 2010

Posts: 946

D L Bahler

Member

|

Member

Joined: May 2010

Posts: 946 |

Will,

Thanks for the reply

I didn't intend that all timbers got carted off the scribe floor, obviously that would be impractical.

Das Ständebuch, by Jost Amman. Interesting.

This, I can tell you, is a Swiss carpenter's setup. The reason I say that is because the name, Jost Amman, is typically Swiss. The name Jost, spelled Yost, is to this day used among the Amish in America, and spelled Jost is a fairly common name in Switzerland. The surname Amman, also, is immediately recognizable to me as the name of one Jacob Amman, from whom the Amish derive their name. This fellow, in fact, was from Zürich.

Judging from this, and from what I know from study, this would have been a typical South German/Swiss/Austrian setup of this time period. Notably missing are later developments such as the stichaxt (whose immediate predecessor, the Kreuzaxt, is seen twice)

Also notice that you don't see any saws (aside from the big crosscut) or chisels, neither of which are used much if at all in the German tradition. How many of you would be comfortable cutting your mortises without a chisel? Or even without a saw?

Also, Will, notice that these guys seem to have another thing in common with your setup, the majority of their timbers are out in the open, but in the upper left corner you can see there is a shelter of sorts.

The works of Amman are very valuable for such observations, he is said to have paid great attention to detail and accuracy, and his works have been used to gain tremendous insights into this period. Das Ständebuch in particular is an extremely valuable collection of woodcuts showing a number of period (1560's) artisans at work in excellent detail.

If you have any other such images, I would love to see them. I strive to use primary sources like these in my research as much as possible.

Also, I like and appreciate your insights, Will. I am merely trying to set up my work for an old-world traditional carpenter's setup, using the old ways and tools. So whenever I can hear from someone who has done it such as yourself, I eat it right up! Keep it coming...

My eventual goal is to do things just about like the picture you have here, with a few more modern tools here and there just for the fact that this is a business. I am the kind of guy that if there is any way I can make something instead of buying it, I will!

Sine I made some of my earlier comments, I have read some more, and think I may have to revise a bit.

I am becoming more and more convinced that the early American carpenter's also worked their timbers a lot lower than framers do now, and that our working habits are perhaps a product of the fact that we have been influenced by later developments in building. Does anyone have any evidence, such as drawing and engravings, to suggest that this may be a false conclusion?

If this is a true conclusion, then by extension my theory regarding the slick has to be discarded.

DLB

|

|

|

Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26123

04/02/11 10:13 PM Re: What to look for in a slick? Which one to get?

[Re: D L Bahler]

#26123

04/02/11 10:13 PM

|

Joined: Sep 2009

Posts: 6

Markus Nyman

OP

OP

Member

|

OP

Member

Joined: Sep 2009

Posts: 6 |

It is so nice to see that this topic has been revived while I have been away. I find the question of tool preferences and working heights very interesting, and it really would deserve a thread of its own. With my level of ignorance, it will take someone else though, to keep up the conversation at this stage. But I certainly yearn to see and hear more about the topic.

|

|

|

|

|