|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32322

05/31/14 12:53 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32322

05/31/14 12:53 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Also, where do you do workshops? Have you ever done one in Northern California?

No, but if you want to host one, I'm willing to travel out there and teach you, all. Are those substantially more difficult if the pitch is other than 12/12? I haven't personally cut one other than 12/12 but I was shown how to do it, once. Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32325

06/02/14 12:15 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32325

06/02/14 12:15 PM

|

Joined: Oct 2002

Posts: 209

Will B

Member

|

Member

Joined: Oct 2002

Posts: 209 |

Regarding the step-lap versus simple birdsmouth question:

the step-lap is meant to resist rafter thrust; if there's no thrust, no need to use it and a simple birdsmouth will suffice. I think you would rarely find step-laps in buildings with purlin plates, for example, traditionally. It could be argued, though, that with shrinkage there could be the potential of thrust at the rafter foot, however small. So a step-lap would be a preferable joint at the wall plate.

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32440

07/22/14 01:31 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32440

07/22/14 01:31 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

A client of mine who is cutting his own frame asked for a step lap review. So I took some pics of the different methods. His rafter tail and step are both 2" thick. If it was 1.5", then you would use the tongue of the framing square. If it was 3.75" (for some reason), then you could rip a board and hold it alongside the square at the right pitch. So I showed him 3 ways to figure out how to lay out the joint. Method 1, and perhaps the easiest. You just need a framing square for this. Draw a perpendicular line somewhere on some lumber. If the tail is 2" thick then use the blade (the wider side) of the square. The roof pitch on this barn is 9:12. So hold 9:12 on the square, with the 9 on the edge of the timber at the line. Draw a line where it intersects the perpendicular line:  Then repeat with the blade of the square putting 12 on the corner.  Those 2 intersections give you the horizontal and vertical widths for the step lap. Now you just have to figure out which one to apply where.  At 12:12, the vertical and horizontal would be the same, right. So if the roof pitch is less than 12:12, as it is here, then the horizontal distance should be greater than vertical distance.  Continued in the next post... www.uncarvedblockinc.com

Last edited by timberwrestler; 07/22/14 01:32 PM.

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32441

07/22/14 01:44 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32441

07/22/14 01:44 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

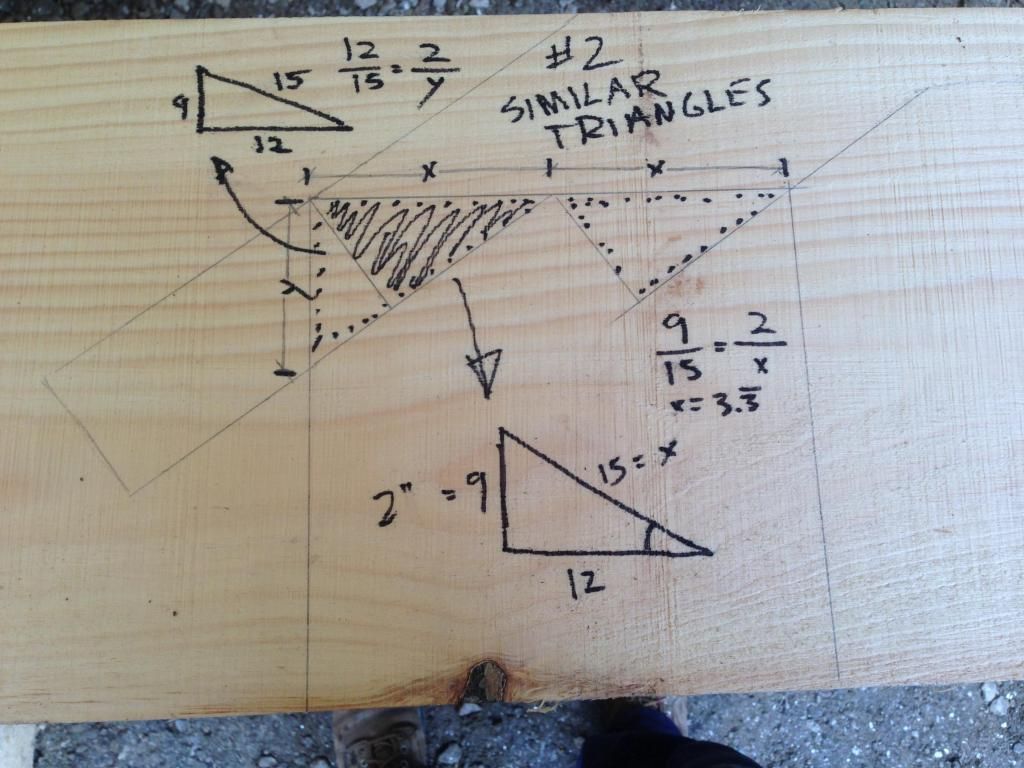

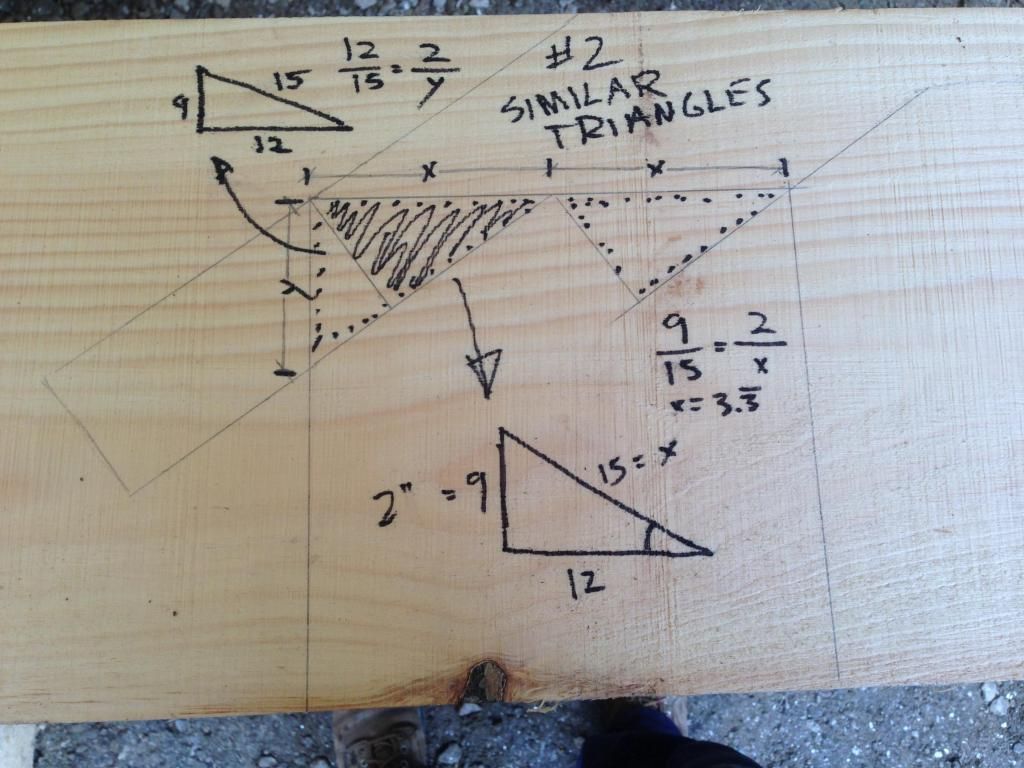

OK, here's method 2. This method is also pretty easy, and is especially easy with a 9:12. This method uses similar triangles.  It helps to draw a little cross section of the plate (this one is by no means to scale. There's a bunch of triangles in there, and if you can solve for some unknowns, then you can get all of the numbers that you need. You'll need the diagonal or hypotenuse of the roof pitch triangle. The rise is 9, the run is 12 (or maybe 10 if you're in Europe or Japan), so in this case the diagonal (also called the rafter length) is conveniently 15. It's a 3/4/5 triangle. If it's not, then you can use the Pythagorean theorem to solve for it. You want to know 'x' in the drawing, which is equivalent to the hypotenuse, or 15. We know the rise of that shaded triangle, as it's 2", which is equivalent to the rise of the roof pitch (9). Cross muliply, you get 3.33 You want to solve for 'y', which is our vertical drop, that's also equivalent to the hypotenuse (15). This time our known value is the base of that triangle, which is 2", the same as our 12. Cross multiply, you get 2.5". These numbers can be checked with another one of the methods. www.uncarvedblockinc.com

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32442

07/22/14 02:28 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32442

07/22/14 02:28 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

OK, here's method 2. This method is also pretty easy, and is especially easy with a 9:12. This method uses similar triangles.  It helps to draw a little cross section of the plate (this one is by no means to scale. There's a bunch of triangles in there, and if you can solve for some unknowns, then you can get all of the numbers that you need. You'll need the diagonal or hypotenuse of the roof pitch triangle. The rise is 9, the run is 12 (or maybe 10 if you're in Europe or Japan), so in this case the diagonal (also called the rafter length) is conveniently 15. It's a 3/4/5 triangle. If it's not, then you can use the Pythagorean theorem to solve for it. You want to know 'x' in the drawing, which is equivalent to the hypotenuse, or 15. We know the rise of that shaded triangle, as it's 2", which is equivalent to the rise of the roof pitch (9). Cross muliply, you get 3.33 You want to solve for 'y', which is our vertical drop, that's also equivalent to the hypotenuse (15). This time our known value is the base of that triangle, which is 2", the same as our 12. Cross multiply, you get 2.5". These numbers can be checked with another one of the methods. More coming. www.uncarvedblockinc.com

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32443

07/22/14 02:29 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32443

07/22/14 02:29 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

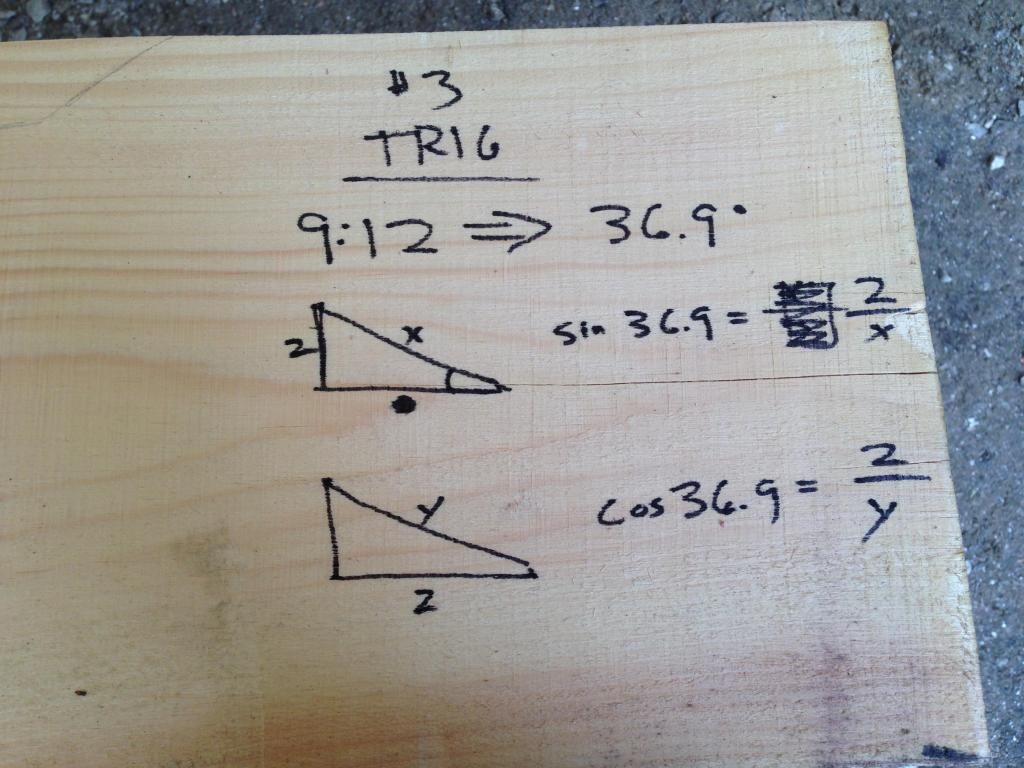

Method 3: Trig I'm not going to elaborate on this one much. Draw same triangles, find pitch angle, find known values, solve for unknowns.

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32444

07/22/14 02:44 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32444

07/22/14 02:44 PM

|

Joined: Nov 2005

Posts: 305

timberwrestler

Member

|

Member

Joined: Nov 2005

Posts: 305 |

That gives us something like this:  So I snapped lines instead of using a combo square, because the piece had a little bow in it, and sometimes it's just easier. Saw the diagonal rafter tail portion (or axe it as Will mentioned).  Clean it up with a chisel or something. Ideally, try to not dish the surface out, because the next part is referenced off that surface.  The next part is the way that I was taught, and it makes sense to me. I've tried to think of an easier way to do this, but haven't yet. So, holding chisel vertical, put corner of chisel somewhere around middle of step part, line up the top of chisel parallel to the surface below (because they're in the same plane). Keep the chisel maybe 1/4" in from the line, because it's going to want to wander.  Do the same on the other side (you're severing the end grain), then chisel out waste in middle. Repeat repeat.  Be careful as you don't want to undercut the triangle that's left in the middle. As you start to get closer, you can set a combo square a little less than what you want (less than 2"), to check for perpedicular off the rafter tail cut. Pare and chop till you get it right on. www.uncarvedblockinc.com

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32445

07/22/14 02:53 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#32445

07/22/14 02:53 PM

|

Joined: Jan 2008

Posts: 918

bmike

Member

|

Member

Joined: Jan 2008

Posts: 918 |

nice reply, thanks for sharing the pics and the process...!

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#33036

06/21/15 12:04 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#33036

06/21/15 12:04 PM

|

Joined: Jun 2015

Posts: 1

Mark_Collins

Member

|

Member

Joined: Jun 2015

Posts: 1 |

I know by now this is a really old thread, I came upon it while I was trying to remember how I laid out and cut the step laps for my barn. The layout didn't seem especially difficult but like everyone else I never found a way to make the cuts with power tools. I had 68 joints to cut and made it a sport to cut them quickly and accurately. The best way I found to cut them was to start as suggested earlier, but with a variation for the pocket.

Saw the shoulder of the seat with a good hand saw and chisel out in between.

Now, don't go for your framing chisel. Get the corner chisel. Its amazing how good a corner chisel is for hogging out the bulk of material. Forget about the corners, it'll work fine but you don't really save that much time with a corner chisel there. Use whichever chisel you have in your hand for the corners. It's also good for any mortise that's not drilled first. Get a sturdy one and hit it hard and fast and don't worry about being nice to your chisel. Stay away from the lines as you can clean up better with a flat chisel.

Drink coffee, maybe more coffee.

You've got a long row of joints that are just alike so you don't have to rethink each one and you can make good time here.

Hope this is helpful and thanks to all for the tips!

Mark

|

|

|

Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#33037

06/21/15 12:41 PM Re: Cutting Step Lap Rafter Seat

[Re: ATC]

#33037

06/21/15 12:41 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Thanks for sharing your methods.

Jim Rogers

Whatever you do, have fun doing it!

|

|

|

|

|