|

2" auger bits

#6064

01/31/06 12:53 AM 2" auger bits

#6064

01/31/06 12:53 AM

|

Joined: Nov 2005

Posts: 15

topshelf

OP

OP

Member

|

OP

Member

Joined: Nov 2005

Posts: 15 |

Can anyone tell me a good source for 2" auger bits? It seems like not too many people make them anymore. I heard that you can get them from Irwin but only by special order. Has enyone teied using a milwaukee or dewalt self feed bit to rough out a mortise? It seems like they may stay sraighter than an auger and can easily add an extension. I am also thinking about trying to use my drill press with an adjustable stand for the beams. Any thoughts?

|

|

|

Re: 2" auger bits

#6065

01/31/06 02:43 AM Re: 2" auger bits

#6065

01/31/06 02:43 AM

|

Joined: May 2002

Posts: 218

Emmett Greenleaf

Member

|

Member

Joined: May 2002

Posts: 218 |

getting a big hole to maintain desired alignment when you drill is a challenge. Augers tend to make their own path in some woods. Shipwright bits of good quality can be controlled somewhat easier in a heavy weight drill. Cutting a 2" hole for your mortise followed by a square corner chisel may save a lil time but you are crowding the usual max dimension of the mortise.

In really heavy stock a set of clamps, a metal frame and a large electromagnet jig holding the drill (kinda like a portable drill press) has been used to keep the holes straight when boring thru for pegs. You may find a picture of this on the Franklin Farm project file.

Whatever keeps you in control is what works best.

|

|

|

Re: 2" auger bits

#6066

01/31/06 12:22 PM Re: 2" auger bits

#6066

01/31/06 12:22 PM

|

Joined: Nov 2003

Posts: 1,124

Mark Davidson

Member

|

Member

Joined: Nov 2003

Posts: 1,124 |

Try Jim Rogers "tools for sale" post in the tools forum.

|

|

|

Re: 2" auger bits

#6067

01/31/06 02:28 PM Re: 2" auger bits

#6067

01/31/06 02:28 PM

|

Joined: Apr 2002

Posts: 895

daiku

Member

|

Member

Joined: Apr 2002

Posts: 895 |

Regarding the self feed bits: You'll be forever pulling the bit out to clear the chips. Then you have to get the screw tip restarted in the hole. While trying to minimize the number of pull-outs, you inevitably leave it in too long, and the chips will jam, and you'll be pulling them out with a needle nose pliers. DAMHIKT.

CB.

--

Clark Bremer

Minneapolis

Proud Member of the TFG

|

|

|

Re: 2" auger bits

#6068

02/01/06 02:13 PM Re: 2" auger bits

#6068

02/01/06 02:13 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

I was taught and it has been my experience to not attempt to clear the chips while boring a mortise. The spiral twist of the bit should clear the chips to the surface of the timber, even in oak. Once a bit has started it path to the bottom of the mortise, it should not be stopped and removed to clear chips for the mentioned reason "you have to get the screw tip restarted in the hole." Using a boring machine with the proper sized bit for the mortise is the key. Once the bit has reached the bottom of the mortise the handles of the boring machine are turned in reverse to "back out" the lead screw tip from the thread it has created in the bottom of the mortise. This turning in reverse one full revolution of the handles will back out the tip and then you engage your lifting mechanism to lift the bit and all current chips out of the hole. We recently repaired a shear pin on a boring machine due to the operator not understanding this procedure (or old age of the worn shear pin). Understanding how to use this tool is important.  Hope this helps. Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: 2" auger bits

#6069

02/01/06 03:26 PM Re: 2" auger bits

#6069

02/01/06 03:26 PM

|

Joined: Apr 2002

Posts: 895

daiku

Member

|

Member

Joined: Apr 2002

Posts: 895 |

My point exactly. The "self feed" bits that Topshelf was referring to are shaped like a forstner bit, but with a screw tip. They have no auger to clear the chips. CB.

--

Clark Bremer

Minneapolis

Proud Member of the TFG

|

|

|

Re: 2" auger bits

#6070

02/01/06 05:24 PM Re: 2" auger bits

#6070

02/01/06 05:24 PM

|

Joined: Nov 2005

Posts: 15

topshelf

OP

OP

Member

|

OP

Member

Joined: Nov 2005

Posts: 15 |

Thanks for all the input. I was thinking about trying to build a cheap man's modern style beam drill using a drill guide or possibly using my drill press since I only have 3 or 4 posts that I need to drill mortises in. Anyone here done that?

|

|

|

Re: 2" auger bits

#6071

02/01/06 06:14 PM Re: 2" auger bits

#6071

02/01/06 06:14 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

I wouldn't try the drill press. It is easier to carry a drill to a post than a post to a drill.

For that many mortises have you considered using a t-auger? If it is sharp, it cuts well and the slower pace allows good control.

Aside from that, I would get a 1/2" drill with a big long handle out the side and a clutch to prevent injury and a 2" auger bit and make a guide to show you square in 2 directions and drill them that way. (I simply screw 2 1x6's about 7" long together in an L shape making sure the ends are cut square and then place it where the bit is in the corner as I drill the hole--it's a cheap, quick drill guide).

Or you could get a boring machine like the one in Jim's photo. They work well.

The self-feed bits such as plumbers/electricians use are practically worthless for drilling mortises because as daiku said they don't clear chips.

Also, I wouldn't worry about the bit wandering when drilling to typical mortise depth. Your chisel can make quick work of correcting any slight misalignment. I would drill any through mortises from both sides, though.

I wish I had a good source for a 2" bit, but I cut the end off a T-auger to get mine.

Good luck,

Gabel

|

|

|

Re: 2" auger bits

#6072

02/01/06 06:45 PM Re: 2" auger bits

#6072

02/01/06 06:45 PM

|

Joined: Nov 2005

Posts: 15

topshelf

OP

OP

Member

|

OP

Member

Joined: Nov 2005

Posts: 15 |

I actually bought a 2" Vintage bit off of E-bay that has a square end. I may try to cut it off and use it in my drill. It has large gaps between the augers unlike the ship auger bits of today. My concern is that mine only has a single cutting edge which I see many old Beam drills have. I see that some of the older 2" bits have 2 cutting edges. It seems like they may stay more true and not wander. I guess I should look for an old beam drill...

|

|

|

Re: 2" auger bits

#6073

02/03/06 12:36 AM Re: 2" auger bits

#6073

02/03/06 12:36 AM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Originally posted by daiku:

My point exactly. The "self feed" bits that Topshelf was referring to are shaped like a forstner bit, but with a screw tip. They have no auger to clear the chips. CB. I'm not familiar with the types of bits he was intending to use, that's why I posted the caution........

Whatever you do, have fun doing it!

|

|

|

Re: 2" auger bits

#6074

02/03/06 04:41 AM Re: 2" auger bits

#6074

02/03/06 04:41 AM

|

Joined: Dec 2005

Posts: 75

Dan F

Member

|

Member

Joined: Dec 2005

Posts: 75 |

For a heavy duty electric drill, as mentioned above, you might consider a 1 1/2" bit. I like Milwaukee's bit. It's about 6-7" long with about 4-4 1/2" of twist. Mortises more than 5" or so may require attention to chip removal. I believe Irwin still makes the long 1 1/2" bit (16" or so?)and they're decent bits althogh I've never used them for mortises. The narrower shank may lose its trueness doing the demand work of mortises.

For the most part, the critical points of the mortise are at the surface for the purpose of locating the joint. If the sides are cut a little wide (in this case by clean-up with a chisel), it won't affect the joint. The ends of the mortise should be more accurate, especially in a brace mortise.

Using a smaller bit means more hand work, but if that's what you have...... This bit has worked well for me in my boring machine too, with no modification except an extension to the shank if needed for length. Good luck.

|

|

|

Re: 2" auger bits

#6075

02/04/06 08:41 PM Re: 2" auger bits

#6075

02/04/06 08:41 PM

|

Joined: Sep 2003

Posts: 5

Chris Gunn

Member

|

Member

Joined: Sep 2003

Posts: 5 |

|

|

|

Re: 2" auger bits

#6076

02/05/06 03:36 AM Re: 2" auger bits

#6076

02/05/06 03:36 AM

|

Joined: Mar 2002

Posts: 1,198

northern hewer

Member

|

Member

Joined: Mar 2002

Posts: 1,198 |

hello all:

Well just couldn't help hopping in here, great topic.

Well from my perspective, and experience for what it may be worth, here is what I used for many years and hundreds of mortices later. My preference and what I used for quick and accurate work, and for rough hewn surfaced timber was a 2" shipwright's auger for a 2" mortice, driven by a heavy duty 1\2" electric drill (be careful). I levelled the timber using the markout lines on the end, and then using a short torpedo level along 2 of the sides of the auger started the inward travel of the bit.

I then stopped, and checked for level once again and then finished to the depth. I had a short 1" by 2" stick placed on the top of the timber, and under the case of the drill to stop the inward travel. The length of this stick was pre determined for that particular mortice, For mortices that went right through, I drilled half way from the two opposing sides, this always seemed to work well, in my books nothing works better than a shipwrights auger for accuracy. this proceedure needs help from a journeyman or helper.

NH

|

|

|

Re: 2" auger bits

#6077

02/06/06 03:20 PM Re: 2" auger bits

#6077

02/06/06 03:20 PM

|

Joined: Nov 2005

Posts: 15

topshelf

OP

OP

Member

|

OP

Member

Joined: Nov 2005

Posts: 15 |

Thanks again for you input since I am very new to this. You mention a 2" shipwrights auger bit. Do you have a good source for these? Also I was wondering about the through mortise and whether to drill as far as I could from one side and the do the remainder from the oposite side or to just go half way from each side. It seems that it would be more accurate going half way from each side. Also when you use the 2" auger bit do you just us it to drill the ends of each mortise or do you drill consecutive holes the entire length of the mortise? The feedback here was that if you drilled continous 2" holes that the overall width of the mortise would be slightly wider than 2".

|

|

|

Re: 2" auger bits

#6078

02/07/06 02:39 PM Re: 2" auger bits

#6078

02/07/06 02:39 PM

|

Joined: Mar 2002

Posts: 1,687

Jim Rogers

Member

|

Member

Joined: Mar 2002

Posts: 1,687 |

Originally posted by topshelf:

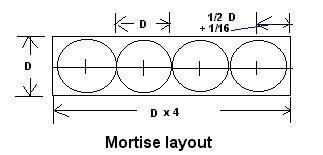

Also when you use the 2" auger bit do you just us it to drill the ends of each mortise or do you drill consecutive holes the entire length of the mortise? The feedback here was that if you drilled continuous 2" holes that the overall width of the mortise would be slightly wider than 2". When we layout a mortise we do it like this:  And we use a two inch bit to do a two inch mortise. We bore half way through from each side when doing a through mortise. We scribe the outline of the mortise with a knife to prevent the bits from "chipping out" the wood outside the perimeter of the mortise.  When laid out and bored correctly it will not be outside the lines and when squared up will be ok. Most mortises could have a housing on one side or both, and in those cases the side towards the housing will be covered by the timber with the tenon on it and the mortise shoulder will not be seen. When the mortise only has a housing on one side such as a brace mortise then care should be taken to not bore "outside the line". Hope this helps. Jim Rogers

Whatever you do, have fun doing it!

|

|

|

Re: 2" auger bits

#6079

02/08/06 12:33 AM Re: 2" auger bits

#6079

02/08/06 12:33 AM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

Originally posted by topshelf:

The feedback here was that if you drilled continous 2" holes that the overall width of the mortise would be slightly wider than 2".[/QB] In my experience that is exactly what you want. Gabel

|

|

|

Re: 2" auger bits

#6080

02/08/06 03:10 AM Re: 2" auger bits

#6080

02/08/06 03:10 AM

|

Joined: Nov 2005

Posts: 15

topshelf

OP

OP

Member

|

OP

Member

Joined: Nov 2005

Posts: 15 |

Thanks again for all the info. I never thought I would get the feedback from this forum. It is obvious you guys love what you do. Now that you have been so much help on drilling the mortise I hve two other questions to go along with it. Should I use a 2" chisel or a 1-1/2 to clean up the mortise? I know that it is probably personal preference but I would love to hear your feedback. Also can someone steer me the right direction on a tenon and rip saw? What to look for in new and used. I would prefer to pay more for quality. By the way I scored one 2" auger bit on E-bay for $3.50 plus shipping. I received it yesterday and it is awsome shape. I waon another one for $10 yesterday. Hopefully that one will be as good. I have been looking at the slicks and chisels but don't really know what to look for. It sounds like the Barr chisels are the way to go if I buy new. debating on a 1-1/2 or 2".

|

|

|

Re: 2" auger bits

#6081

02/08/06 12:39 PM Re: 2" auger bits

#6081

02/08/06 12:39 PM

|

Joined: Nov 2003

Posts: 687

Gabel

Member

|

Member

Joined: Nov 2003

Posts: 687 |

If you get only one chisel, get 1 1/2", as it will oviously do both 1 1/2 and 2" mortises.

If I were going to drill the mortises out like you, I would get a 1 1/2. Some people like to use corner chisels to square up the ends of bored mortises, but I usually don't.

Good luck

|

|

|

Re: 2" auger bits

#6082

02/09/06 01:12 PM Re: 2" auger bits

#6082

02/09/06 01:12 PM

|

Joined: Dec 2003

Posts: 31

Dan Miller

Member

|

Member

Joined: Dec 2003

Posts: 31 |

Choose your chisel width to match the width of your mortices. Akthough you will certainly find exceptions, most joinery is either 1-1/2" mortices set in 1-1/2" off the reference face, or 2" mortices set in 2". (My last project was 1-1/2" mortices set in 2"). Usually the mortice width is consistent throughout the frame. Choosing the width of your chisel to the width of the mortice will make cleaning up faster. Put a ruler to the chisel and make sure it isn't undersized. Oversized chisels can be ground.

For saws, I like an old Disston rip saw from the flea market. Rip saws are easy to re-sharpen. For x-cut, I've been using Stanley Sharptooth saws. They last for about 2 frames, and at $15 can be thought of as disposable. A good 8 point x-cut can be had from the fleas as well, but the sharpening learning curve is steeper than for rips.

Cheers,

Dan

|

|

|

Re: 2" auger bits

#6083

03/01/06 10:42 PM Re: 2" auger bits

#6083

03/01/06 10:42 PM

|

Joined: Oct 2002

Posts: 209

Will B

Member

|

Member

Joined: Oct 2002

Posts: 209 |

Caution!

Using a 2" bit originally designed for a hand tool (like a t-auger or boring machine) may not have the metallurgical qualities required for a higher speed electric drill, so take it very slow if you refit one. I'd be curious to know what an expert in metals and forging could say about this.

|

|

|

|

|